| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

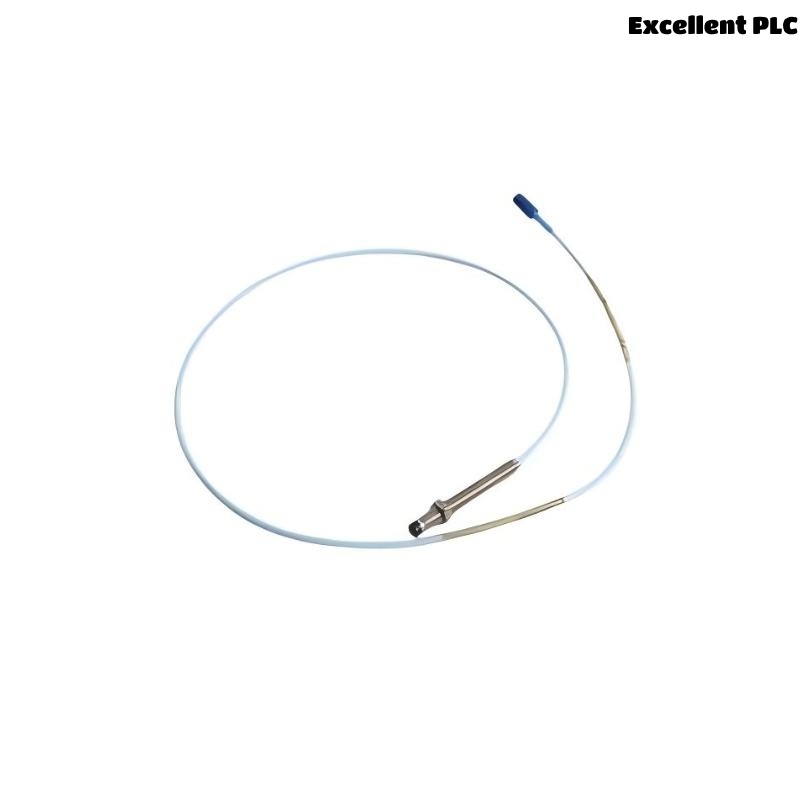

The Bently Nevada 330102-00-96-05-02 3300 XL 8 mm proximity probe is a high-precision sensor designed for monitoring the health of rotating machinery in industrial settings. Part of Bently Nevada’s renowned 3300 XL series, this proximity probe is engineered for durability and accuracy in measuring the displacement and vibration of rotating shafts, providing valuable insights into the condition of critical equipment. It plays a vital role in predictive maintenance, helping industries avoid costly downtime by detecting issues before they result in failures.

With an inductive sensing principle, the 3300 XL proximity probe offers high sensitivity and repeatability, making it ideal for applications that require high reliability and precision. The compact design, with a total length of just 0.5 meters and a lightweight build of 0.161 kg, makes this probe suitable for environments where space is limited, and accurate measurements are essential.

Its rugged design ensures it can perform well even in harsh industrial environments, including those found in power plants, manufacturing facilities, and other industries where machinery health is critical to maintaining production uptime.

Product Specifications:

| Parameter | Description |

|---|---|

| Model | 330102-00-96-05-02 |

| Proximity Type | 3300 XL 8 mm |

| Total Length | 0.5 meters |

| Weight | 0.161 kg |

| Probe Type | 8 mm probe |

| Operating Temp | -40°C to +85°C |

| Output Type | Linear Voltage |

| Frequency Range | 2 Hz to 100 kHz |

| Voltage Output | 10 to 30 VDC |

| Mounting | Standard mounting configuration |

| Compliance | CE, UL |

Applications:

The Bently Nevada 330102-00-96-05-02 proximity probe is widely used in various industrial applications where monitoring of rotating equipment is essential. Some of its primary uses include:

-

Turbine Monitoring: It is highly effective for monitoring turbines in power plants, ensuring smooth and efficient operation by providing early detection of shaft displacement and vibration issues.

-

Compressor Monitoring: This probe is also used to monitor compressors, helping operators identify mechanical problems before they lead to system failure.

-

Pump Health Monitoring: The 3300 XL probe is ideal for use with industrial pumps, detecting vibrations or displacement that could signal mechanical problems.

-

Condition Monitoring Systems: Integrated with condition monitoring systems, the 3300 XL probe provides critical data that allows operators to monitor the health of machinery in real time.

-

High-Speed Machinery: With a frequency range from 2 Hz to 100 kHz, the probe is suited for high-speed applications, providing real-time feedback on machinery health for industries that rely on fast-moving components.

-

General Industrial Applications: The probe can be deployed across a range of industries, including manufacturing, oil and gas, chemical processing, and mining, providing valuable insights into machinery performance and health.

Advantages:

-

Precision and Accuracy: The 3300 XL proximity probe offers exceptional accuracy in measuring vibration and displacement, ensuring that machine performance is constantly monitored with high reliability.

-

Compact and Lightweight: With a length of 0.5 meters and a weight of 0.161 kg, the probe is ideal for installations where space is limited or where weight constraints are a concern.

-

Broad Operating Temperature Range: The probe can function in extreme environments with temperatures ranging from -40°C to +85°C, making it suitable for a variety of industrial environments.

-

Durability in Harsh Environments: Built to withstand challenging industrial conditions, the 3300 XL probe is resistant to vibration, dust, moisture, and other harsh factors that can affect measurement quality.

-

Low Maintenance Requirements: The proximity probe is designed for minimal maintenance, which helps to reduce operational costs and downtime in industrial applications.

-

Compliance with Global Standards: With CE and UL certifications, the probe meets stringent international standards for safety and quality, ensuring reliable operation across various industries.

-

Versatility in Application: It is versatile enough to be used in a wide range of applications, from high-speed machinery to large turbines, offering exceptional flexibility for users.

-

Reliable Integration: The 3300 XL probe easily integrates into Bently Nevada’s 3500 system and other third-party condition monitoring systems, ensuring compatibility with a broad range of monitoring solutions.

FAQ (Frequently Asked Questions)

-

What is the total length of the Bently Nevada 3300 XL 8 mm proximity probe?

-

The total length is 0.5 meters.

-

-

How much does the 3300 XL proximity probe weigh?

-

The probe weighs 0.161 kg.

-

-

What is the operating temperature range for this proximity probe?

-

The probe operates in temperatures ranging from -40°C to +85°C.

-

-

What type of output does the 3300 XL 8 mm proximity probe provide?

-

The probe provides a linear voltage output, making it compatible with most industrial monitoring systems.

-

-

What is the frequency range of the 3300 XL 8 mm proximity probe?

-

The frequency range is from 2 Hz to 100 kHz, allowing it to monitor both low and high-frequency vibrations.

-

-

Can the 3300 XL proximity probe be used in hazardous environments?

-

The probe is designed for industrial environments but may require additional certification for use in hazardous or explosive areas. Please verify specific certification requirements.

-

-

Is the Bently Nevada 3300 XL probe compatible with other condition monitoring systems?

-

Yes, it can be integrated into Bently Nevada’s 3500 monitoring system, as well as other compatible systems.

-

-

What industries benefit the most from using the 3300 XL proximity probe?

-

The 3300 XL probe is beneficial for industries such as power generation, oil and gas, manufacturing, and mining, where rotating machinery health is critical.

-

-

How does the 3300 XL proximity probe help with predictive maintenance?

-

By providing real-time displacement and vibration data, the probe helps identify potential issues before they result in machinery failure, allowing for proactive maintenance.

-

-

Is the installation of the 3300 XL proximity probe difficult?

-

No, the probe is designed for easy installation, with standard mounting configurations that ensure a seamless integration into existing monitoring setups.

-

Recommended Models (Same Series/Related Models)

| Model | Description |

|---|---|

| 330102-00-96-05-02-01 | 3300 XL 8 mm Proximity Probe with extended cable length for large systems. |

| 330102-00-96-05-02-03 | 3300 XL 8 mm Proximity Probe designed for high-temperature applications. |

| 330102-00-96-05-02-04 | 3300 XL 8 mm Proximity Probe with integrated diagnostics for real-time monitoring. |

| 330102-00-96-05-02-05 | 3300 XL 8 mm Proximity Probe with enhanced shielding for harsh industrial environments. |

| 330102-00-96-05-02-06 | 3300 XL 8 mm Proximity Probe for high-speed machinery with extended frequency response. |

| 330102-00-96-05-02-07 | 3300 XL 8 mm Proximity Probe for large rotating equipment with increased measurement range. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 24701-28-10-00-040-00-02 | High-performance control unit with robust diagnostics for process automation. |

| 330103-00-12-10-12-00 | Versatile module designed for standard industrial control and monitoring tasks. |

| 330103-00-12-15-01-05 | Advanced version with additional I/O ports and real-time data processing capabilities. |

| 24702-28-11-00-045-00-03 | Compact model optimized for integration in smaller systems with high control accuracy. |

| 330104-00-12-20-05-10 | Industrial-grade controller with expanded network communication features for large systems. |

| 330105-00-13-10-15-02 | Enhanced model with higher reliability and fail-safe mechanisms for critical operations. |

Excellent PLC

Excellent PLC