| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

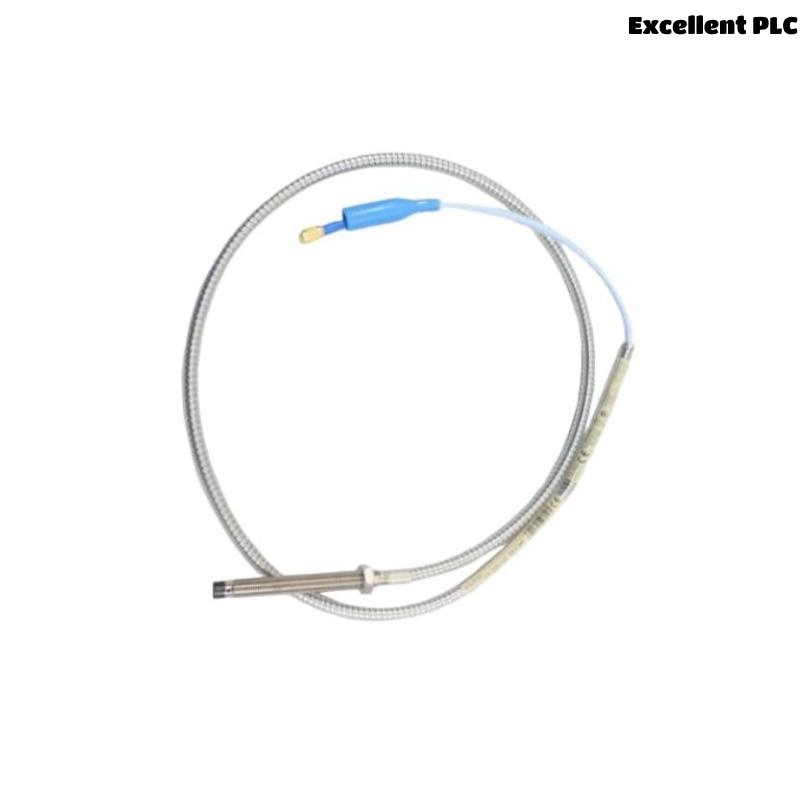

The Bently Nevada 330102-03-20-10-02-05 3300 XL 8 mm Proximity Probe is a precision-engineered sensor designed for continuous measurement of shaft vibration, axial displacement, and machine condition monitoring in critical rotating equipment. As part of the globally recognized 3300 XL series, this proximity probe is a trusted solution for industries such as power generation, oil & gas, petrochemical, manufacturing, and heavy industry, where equipment protection is vital.

Utilizing advanced eddy-current, non-contact sensing technology, the 3300 XL probe ensures highly accurate measurements of shaft movement and vibration, providing real-time data to monitoring and protection systems. With its 8 mm tip, durable construction, and compatibility with harsh industrial environments, it forms a core element of machinery protection systems designed to extend equipment life and prevent unplanned downtime.

Key Features

-

8 mm Probe Tip Diameter: Provides precise shaft vibration and displacement measurement for critical machinery.

-

Non-Contact Eddy Current Technology: Ensures wear-free, reliable operation without physical contact with machine components.

-

20 ft Cable Length: Pre-configured probe with a 20-foot integral cable for extended installation flexibility.

-

Robust Industrial Design: Stainless steel probe body offers excellent resistance to vibration, contaminants, and harsh operating conditions.

-

Wide Operating Temperature Range: Capable of withstanding high and low temperatures for diverse industrial applications.

-

High Sensitivity and Stability: Detects small vibrations or shaft displacements with superior accuracy.

-

Seamless System Integration: Fully compatible with Bently Nevada 3300 XL extension cables, Proximitor sensors, and monitoring systems.

-

Easy Installation: Standard thread mounting ensures straightforward setup in turbines, compressors, pumps, and motors.

-

Global Certifications: CE, ATEX, and RoHS compliant for safe, international deployment.

-

Long Service Life: Designed for durability and minimal maintenance in continuous monitoring applications.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 330102-03-20-10-02-05 |

| Product Type | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm (0.315 inches) |

| Cable Length | 20 feet (6.1 meters) integral cable |

| Sensing Technology | Eddy-current, non-contact |

| Measurement Range | 0 to 2 mm (adjustable based on system configuration) |

| Operating Temperature Range | -40°C to +120°C |

| Frequency Response | DC to 20 kHz |

| Mounting Thread Size | 3/8-24 UNF standard thread |

| Electrical Connection Type | Compatible with 3300 XL Proximitor and extension cables |

| Protection Class | IP67 (dust-tight and water-resistant) |

| Certifications | CE, ATEX, RoHS compliant |

| Dimensions | Total Length : 1.0 meter |

| Weight | 0.323 kg |

Industry Applications

-

Power Generation: Shaft vibration and axial displacement monitoring in turbines, generators, and auxiliary systems.

-

Oil & Gas: Vibration monitoring for compressors, pumps, and rotating machinery in upstream, midstream, and downstream operations.

-

Petrochemical and Chemical Processing: Protection of critical machinery in refineries, chemical plants, and industrial processes.

-

Manufacturing: Ensures reliable operation of motors, conveyors, compressors, and production equipment.

-

Mining and Heavy Industry: Monitors heavy-duty machinery such as crushers, mills, and large pumps for vibration abnormalities.

-

Water and Wastewater Treatment: Vibration detection in pumps, turbines, and motors to prevent failures.

-

Marine and Offshore: Ensures reliable performance of rotating equipment in harsh marine environments.

Product Advantages

-

Non-Contact Measurement: Prevents wear on both probe and rotating equipment, ensuring long operational life.

-

High Precision Monitoring: Ideal for detecting small-scale shaft vibrations or axial displacements to prevent damage.

-

Rugged Construction: Stainless steel design withstands vibration, contaminants, and challenging environments.

-

Extended Cable Configuration: 20 ft integral cable simplifies installation in remote or hard-to-access locations.

-

Fully Compatible with 3300 XL Systems: Seamless integration with Bently Nevada Proximitor sensors and monitoring equipment.

-

Industry-Proven Performance: Trusted across industries for reliable, long-term machine protection.

-

Global Certification Compliance: Meets international safety and environmental standards, suitable for worldwide applications.

-

Wide Application Flexibility: Supports monitoring in turbines, compressors, pumps, motors, and other rotating assets.

-

Minimal Maintenance: Designed for reliable, continuous operation with low maintenance demands.

-

Real-Time Data Acquisition: Provides immediate, real-time vibration data to facilitate proactive maintenance strategies.

Frequently Asked Questions (FAQ)

-

What does the 330102-03-20-10-02-05 Proximity Probe monitor?

It measures shaft vibration, radial displacement, and axial movement in rotating machinery. -

What is unique about the 20 ft cable length?

The integral 20 ft cable allows for installations where the monitoring equipment is positioned further from the probe. -

What type of sensing technology does this probe use?

It utilizes eddy-current, non-contact technology for precise and wear-free vibration measurement. -

Is the probe compatible with other Bently Nevada systems?

Yes, it integrates with Bently Nevada 3300 XL Proximitor sensors, extension cables, and monitoring equipment. -

What industries typically use this proximity probe?

Common industries include power generation, oil & gas, petrochemical, manufacturing, mining, and water treatment. -

What is the probe’s operating temperature range?

The standard operating temperature range is -40°C to +120°C. -

Is the 330102-03-20-10-02-05 suitable for hazardous environments?

Yes, it meets ATEX and CE standards for use in potentially hazardous or explosive environments. -

Can the probe be installed in high-vibration areas?

Yes, its robust design allows for installation in high-vibration industrial environments. -

How is the probe installed?

It uses a standard 3/8-24 UNF threaded mounting arrangement for secure and precise installation. -

What is the measurement range of this probe?

The probe typically provides a measurement range of 0 to 2 mm, configurable based on system setup.

Related Models

| Model | Description |

|---|---|

| 330102-00-20-10-02-05 | 3300 XL 8 mm Proximity Probe with standard 20 ft cable. |

| 330102-00-25-10-02-05 | 3300 XL 8 mm Proximity Probe with extended 25 ft cable. |

| 330104-00-09-10-02-00 | 3300 XL Reverse Mount Proximity Probe for tight installations. |

| 330101-00-16-10-02-05 | 3300 XL 8 mm Proximity Probe with extended length. |

| 330130-040-00-00 | 3300 XL Standard Extension Cable for proximity probes. |

| 330180-91-05 | Velomitor Piezoelectric Velocity Sensor for machinery condition monitoring. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3500/15-05-05-00 | 3500 Series Power Supply Module for monitoring systems. |

| 3500/22M-01-01-00 | Transient Data Interface Module for machinery diagnostics. |

| 3500/33-01-00 | 16-Channel Relay Module for alarm control and protection. |

| 330101-00-14-10-02-05 | 3300 XL 8 mm Proximity Probe for general vibration monitoring. |

| 3500/40-02-00 | 3500 Digital Output Module for critical system control. |

| 330130-045-00-05 | Extension Cable for 3300 XL Proximity Probe configurations. |

Excellent PLC

Excellent PLC