| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

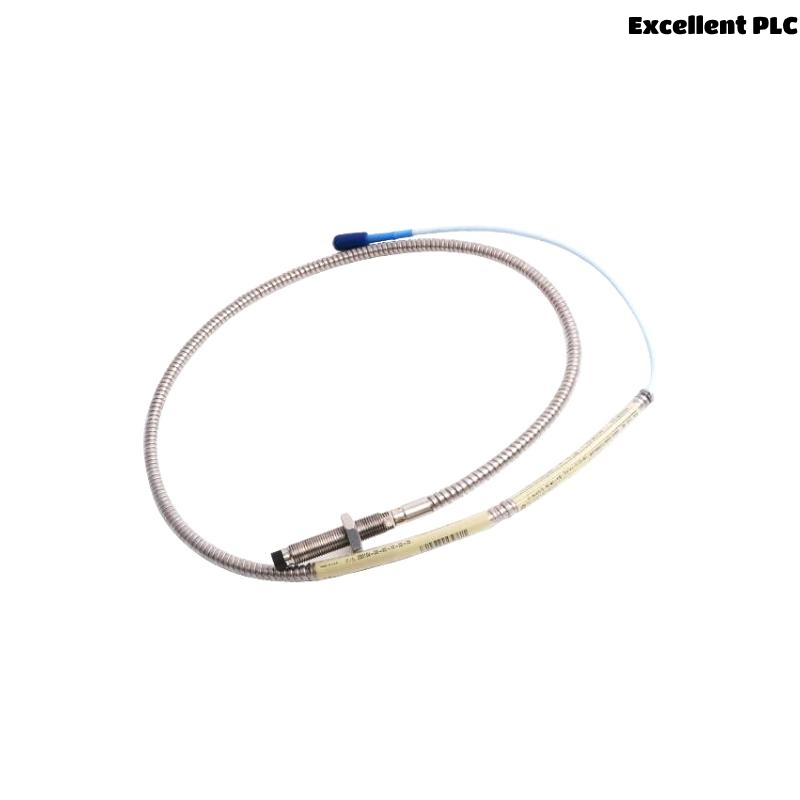

The Bently Nevada 330103-00-03-10-01-05 is a high-performance proximity probe from the renowned 3300 XL 8mm Proximity Transducer System series, designed and manufactured by Bently Nevada, a division of Baker Hughes. This system is engineered specifically for critical machinery monitoring, offering reliable, continuous, and accurate measurements of shaft position and vibration in a wide range of industrial equipment.

The 330103 probe features an 8mm tip diameter, a robust stainless steel construction, and is capable of surviving harsh industrial environments including high temperatures, vibration, and corrosive atmospheres. It is widely used in turbine machines, compressors, pumps, and gearboxes, where precise shaft displacement monitoring is required.

This model adheres to the American Petroleum Institute (API) 670 standard, making it a trusted choice in the oil and gas, power generation, and petrochemical sectors.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330103-00-03-10-01-05 |

| Series | 3300 XL 8mm Proximity Transducer System |

| Tip Diameter | 8 mm |

| Case Material | AISI 304 Stainless Steel |

| Total Length | 1.0 meter |

| Connector Type | Miniature coaxial connector |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Linear Range | 2 mm (80 mils) nominal |

| Output Voltage Range | -2 V to -18 V DC |

| Operating Temperature Range | -35°C to +177°C (-31°F to +350°F) |

| Probe Thread Size | 3/8-24 UNF-2A |

| Weight | 0.323 kg |

| Compliance | API 670, CE, RoHS |

| Typical Applications | Shaft vibration, axial thrust position, eccentricity |

Product Applications

The Bently Nevada 330103-00-03-10-01-05 proximity probe is widely used in mission-critical industrial applications where real-time vibration and position monitoring are essential. Key applications include:

-

Gas and Steam Turbines

-

Centrifugal Compressors

-

Industrial Pumps

-

Gearboxes and Motors

-

Hydroelectric and Wind Turbines

-

Marine Propulsion Systems

Its ability to provide precise displacement measurements makes it indispensable for predictive maintenance and condition monitoring.

Product Advantages

-

API 670 Compliance: Ensures compatibility with industry standards for critical machinery protection.

-

Robust Construction: Stainless steel housing provides excellent durability and corrosion resistance.

-

High Accuracy and Sensitivity: Delivers reliable measurements even under extreme conditions.

-

Wide Operating Temperature Range: Supports deployment in both cryogenic and high-heat environments.

-

Flexible Configuration: Available in multiple lengths and configurations to suit various installation scenarios.

-

Low Noise Performance: Superior signal clarity for accurate monitoring and diagnostics.

-

Field-Proven Reliability: Trusted across industries for long-term stability and performance.

-

Complete System Integration: Seamlessly works with 3300 XL extension cables and drivers for full system integration.

Frequently Asked Questions (FAQ)

-

What is the main use of the 330103-00-03-10-01-05 proximity probe?

It is used to measure the vibration and position of rotating machinery shafts in real-time. -

What makes this probe compliant with API 670?

It meets API 670 criteria for sensitivity, linearity, and environmental durability. -

Can this probe operate in high-temperature environments?

Yes, it can operate at temperatures up to 177°C (350°F). -

What is the output signal type of the probe?

It provides a voltage output that is proportional to the shaft’s position from the probe tip. -

What is the linear range of this proximity probe?

The linear range is typically 2 mm (80 mils). -

Is it compatible with other Bently Nevada systems?

Yes, it is designed to be compatible with the 3300 XL system, including drivers and extension cables. -

How long is the probe cable?

This model comes with a 1.0 meter cable. -

Can the probe be used in corrosive environments?

Yes, the stainless steel body ensures protection in corrosive and industrial environments. -

Is field calibration necessary?

Factory-calibrated for standard shaft materials, but field calibration may be required for different target materials. -

What is the expected lifespan of this probe?

With proper installation and maintenance, it can last several years in continuous operation.

Recommended Related Models (Same Series or Functionally Similar)

| Model Number | Description | Cable Length | Tip Diameter | Notes |

|---|---|---|---|---|

| 330103-00-05-10-01-05 | 5m probe cable length version | 5 meters | 8 mm | Longer cable for extended applications |

| 330104-00-03-10-01-05 | Reverse mount version of proximity probe | 3 meters | 8 mm | Suitable for confined spaces |

| 330130-040-00-00 | Extension cable for 3300 XL 8mm series | 4 meters | N/A | Pairs with probe and driver |

| 330180-90-00 | Proximitor sensor driver for 3300 XL probes | N/A | N/A | Required for signal conditioning |

| 330106-05-30-10-02-00 | Probe with armor and special connectors | 5 meters | 8 mm | Enhanced mechanical protection |

| 330171-XX-XX | Mounting bracket assembly for probes | N/A | N/A | Used for stable installation |

Popular Bently Nevada Models (Same Brand)

| Model Number | Function | Application | Key Feature |

|---|---|---|---|

| 3500/22M | Keyphasor Module | Rotating machinery monitoring | Provides once-per-turn pulse output |

| 3500/42M | Vibration Monitor | Turbines, Compressors | Measures radial, axial vibration |

| 330500 | Accelerometer | Bearing condition monitoring | Piezoelectric sensor |

| 3500/15 | Power Supply Module | System power management | Redundant configuration supported |

| 190501 | Velocity Sensor | Motor and pump monitoring | Non-contact velocity measurement |

| 330980 | Air Gap Sensor | Generator stator monitoring | Accurate distance detection |

Excellent PLC

Excellent PLC