| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

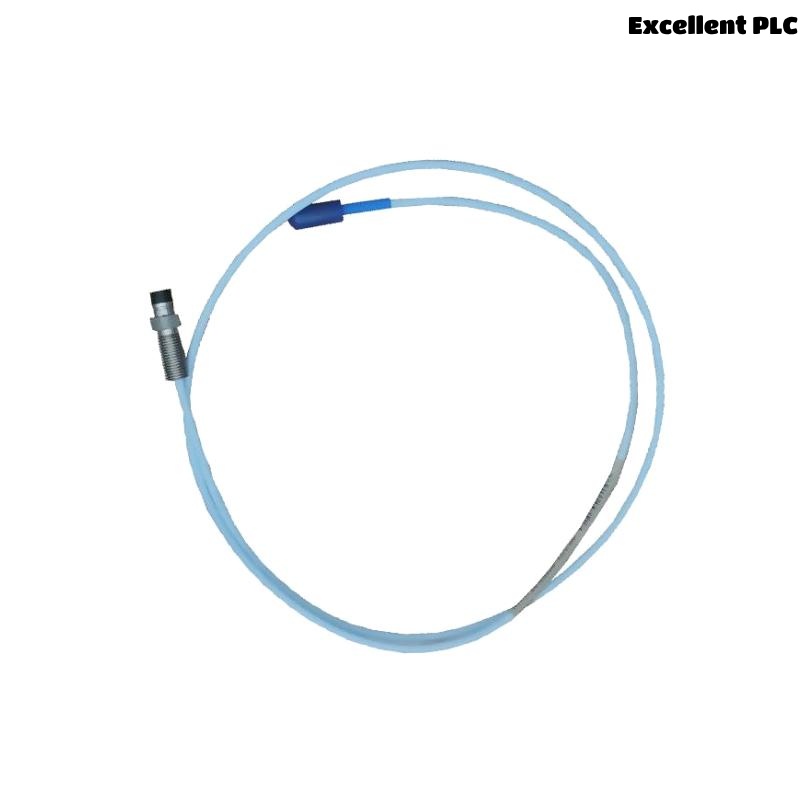

The Bently Nevada 330103-00-03-10-02-00 is a part of the 3300 XL 8mm Proximity Transducer System, a rugged and highly accurate proximity probe solution designed to monitor the dynamic behavior of rotating machinery. It operates based on eddy current measurement principles to detect the relative movement of conductive targets (usually shaft rotors), offering real-time, continuous output signals for vibration, displacement, and thrust measurements.

Manufactured by Bently Nevada, a leader in machine condition monitoring systems, this probe is tailored to meet API 670 compliance and operates reliably in hostile industrial environments such as oil refineries, power plants, and chemical facilities. This specific configuration comes with a 3-meter probe cable and uses the standard 8 mm tip that ensures compatibility with common Bently Nevada transducer systems and proximitor drivers.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Model | 330103-00-03-10-02-00 |

| Series | 3300 XL 8mm Proximity Transducer System |

| Sensing Principle | Eddy current (non-contact displacement measurement) |

| Probe Tip Diameter | 8 mm |

| Tip Material | PPS (Polyphenylene Sulfide), encapsulated |

| Body Material | AISI 304 Stainless Steel |

| Thread Type | 3/8-24 UNF-2A |

| Unthreaded Length | 30 mm |

| Overall Probe Length | 95 mm (excluding connector) |

| Total Length | 1.0 meter |

| Connector Type | Miniature coaxial connector (for extension cable) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Linear Range | 2 mm (80 mils) nominal |

| Voltage Output Range | -2 V to -18 V DC |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Humidity | 100% condensing, sealed electronics |

| Weight | 0.323 kg |

| Compliance Standards | API 670, CE Marked, RoHS |

| Compatible Drivers | 3300 XL Proximitor (e.g., 330180 or 330400) |

Product Applications

The 330103-00-03-10-02-00 proximity probe is essential in industrial machinery protection and diagnostics. Common application areas include:

-

Steam and Gas Turbines

-

Centrifugal and Axial Compressors

-

Canned Motor Pumps and Gear Pumps

-

High-speed Gearboxes

-

Generators and Motors

-

Hydraulic Machinery and Expanders

This probe supports real-time shaft vibration, position, and thrust monitoring, allowing maintenance teams to make predictive decisions, minimize unplanned downtime, and protect expensive rotating assets.

Product Advantages

-

Certified for API 670 Compliance

Built to match the specifications required for critical rotating equipment across oil and gas sectors. -

Accurate and Stable Measurement

Delivers high-fidelity signal output for accurate proximity and vibration readings across the entire linear range. -

Durability in Harsh Environments

Constructed with corrosion-resistant stainless steel and a sealed probe tip for long-term service in wet, high-vibration, and thermally extreme conditions. -

Interchangeability and System Compatibility

Fully compatible with Bently Nevada’s 3300 XL extension cables and drivers, enabling flexible system design and retrofit upgrades. -

Thermal Stability

Consistent performance across a broad operating temperature spectrum—ideal for turbines, compressors, and other high-heat machinery. -

Low Noise Output

Designed with electromagnetic shielding to minimize signal distortion due to electrical noise or RF interference.

Frequently Asked Questions (FAQ)

-

What is the function of the 330103-00-03-10-02-00 proximity probe?

It provides non-contact displacement measurements for shaft vibration and position monitoring in rotating machinery. -

How does it differ from other 3300 XL probes?

This version has specific configuration codes (e.g., “10-02-00”) which define its thread type, connector orientation, and target calibration. -

Can this probe be installed in high-temperature locations?

Yes, it supports continuous operation up to 177°C, suitable for turbine and compressor environments. -

Is the probe cable integral or detachable?

The probe has an integral 3-meter cable that connects to an extension cable via a coaxial connector. -

Does this probe require a dedicated driver?

Yes, it must be paired with a 3300 XL Proximitor driver such as 330180 or 330400 to condition the signal. -

What kind of shaft material is it calibrated for?

Factory calibrated for 4140 steel shafts, with different calibration available upon request. -

Can it be mounted in a reverse configuration?

This specific model is for standard forward mount. Reverse-mount versions are available separately. -

What type of target surface does it detect?

Any conductive metal surface, typically the shaft journal or thrust collar. -

Is field recalibration needed after installation?

Not necessary if installed per Bently Nevada guidelines, but optional calibration can improve precision. -

What is the expected service life?

Typically exceeds 5 years under normal operating conditions with proper installation.

Recommended Related Models (Same Series or Functionally Compatible)

| Model Number | Description | Cable Length | Connector Type | Application Note |

|---|---|---|---|---|

| 330103-00-05-10-02-00 | XL 8mm Probe with 5m cable | 5 meters | Mini coaxial | For longer distance between probe and driver |

| 330104-00-03-10-02-00 | Reverse mount proximity probe | 3 meters | Mini coaxial | Ideal for tight or confined installation spaces |

| 330130-040-00-00 | Extension cable, 4 meters | 4 meters | Mini coaxial to proximitor | Connects probe to proximitor driver |

| 330180-50-00 | 3300 XL Proximitor Driver | N/A | Terminal strip connection | Conditions signal from 330103 probe |

| 330106-05-30-10-02-00 | XL 8mm armored probe, 5m, ruggedized version | 5 meters | Armored coaxial | Enhanced for physically demanding environments |

| 330171-XX-XX | Mounting bracket assembly | N/A | N/A | Facilitates proper probe positioning |

Popular Models from Bently Nevada (Same Brand)

| Model Number | Primary Function | Application Area | Highlight Feature |

|---|---|---|---|

| 3500/22M | Keyphasor Module | Turbines and gearboxes | Delivers once-per-turn signal for phase reference |

| 3500/42M | Vibration Monitor | Compressors, turbines | Measures radial and axial vibration |

| 3500/15E | Power Supply Module | Rack-based monitoring systems | Supports redundant power configurations |

| 330500 | Accelerometer | Bearing and casing vibration | Piezoelectric with high sensitivity |

| 190501 | Velocity Transducer | Pumps and motors | Seismic transducer for low-frequency monitoring |

| 330980 | Air Gap Sensor | Generators | Measures rotor-to-stator air gap |

Excellent PLC

Excellent PLC