| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

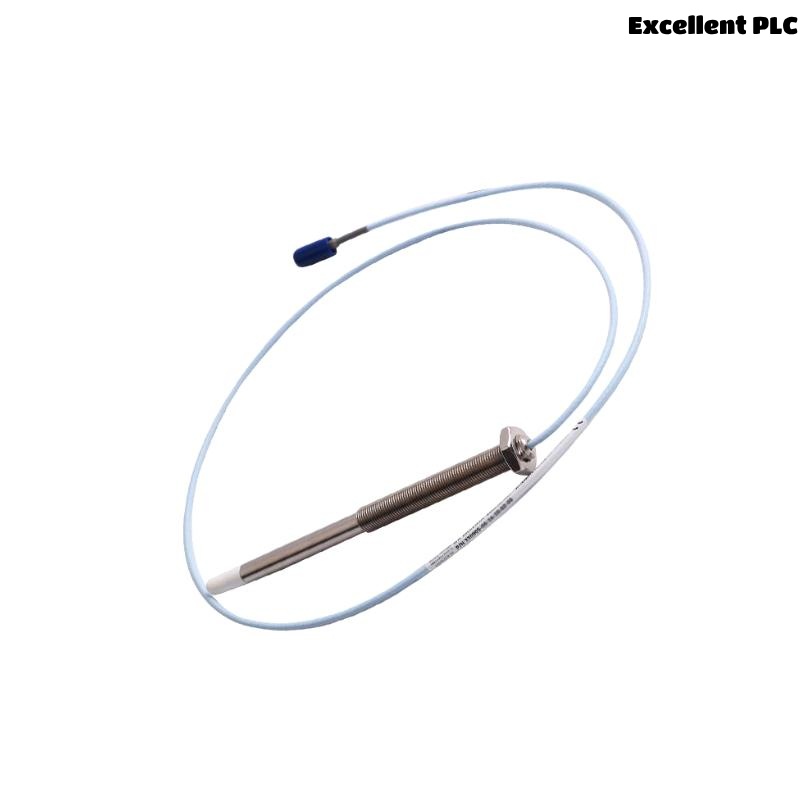

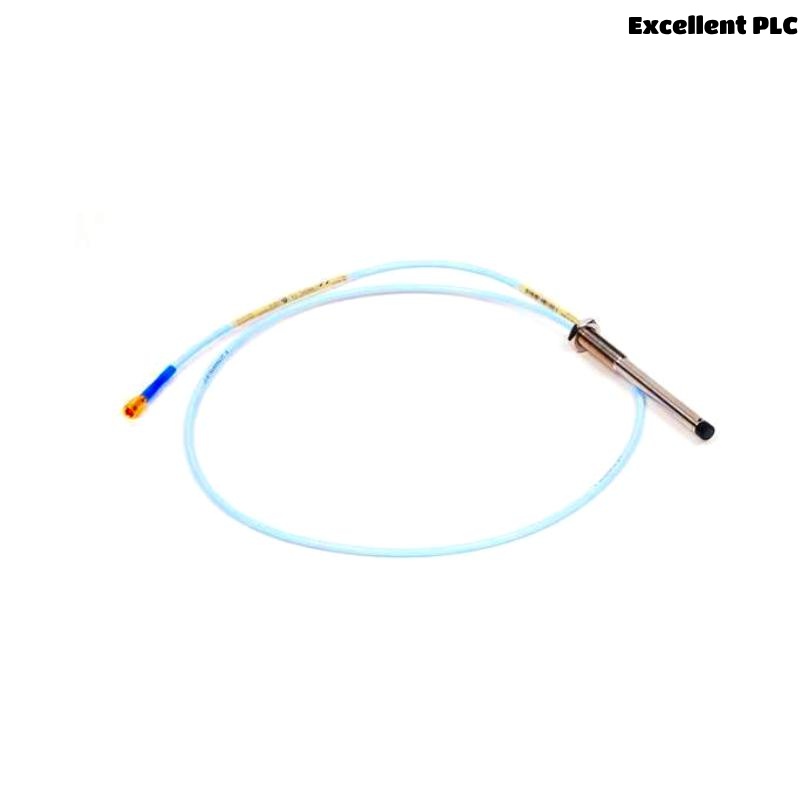

The Bently Nevada 330103-00-03-10-02-05 is a premium-grade proximity probe designed as part of the 3300 XL 8mm Proximity Transducer System, a trusted standard in the field of industrial vibration monitoring and machinery protection. Manufactured by Bently Nevada, a brand under Baker Hughes, this model delivers high-accuracy, non-contact displacement measurements of rotating shaft systems. It is engineered for harsh environments, ensuring reliability in critical machinery applications across power generation, petrochemical, and oil & gas industries.

The 3300 XL series maintains backward compatibility with older 3300 systems while offering improved immunity to radio frequency interference (RFI) and better mechanical integrity. The 330103-00-03-10-02-05 part number corresponds to a specific probe configuration including cable length, connector type, and extension cable compatibility.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330103-00-03-10-02-05 |

| Series | 3300 XL 8mm |

| Sensor Type | Proximity Probe (Eddy Current Type) |

| Sensing Element | 8mm (0.315 in) tip diameter |

| Linear Range | 2 mm (80 mils), with a sensitivity of 7.87 mV/μm (200 mV/mil) ±5% |

| Usable Gap | 0.25 mm to 2.0 mm (10 mils to 80 mils) |

| Total Length | 1.0 meter |

| Connector Type | Standard ClickLoc™ connector |

| Operating Temperature Range | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Humidity | 100% non-condensing |

| Pressure Rating | Sealed for use in high-pressure environments |

| Enclosure Material | AISI 304 Stainless Steel |

| Mounting Thread | 1/4-28 UNF-2A or M8 x 1 (depending on variant) |

| Weight | 0.323 kg |

| Compliance | CE, RoHS, CSA, ATEX (certain configurations) |

Applications

The 330103-00-03-10-02-05 proximity probe is utilized in a wide array of industrial applications where precise, real-time measurement of shaft displacement or vibration is critical. Common application scenarios include:

-

Turbomachinery Vibration Monitoring: For turbines, compressors, and pumps to prevent damage due to imbalance or misalignment.

-

Shaft Position Monitoring: Enables accurate detection of rotor dynamics and shaft centering.

-

Thrust Position Monitoring: For axial displacement analysis in thrust bearing systems.

-

Radial Vibration Monitoring: Helps detect bearing wear or mechanical looseness.

-

Condition Monitoring Systems: Integrated into predictive maintenance solutions across refineries, chemical plants, and power stations.

Product Advantages

-

Backward Compatibility: Fully compatible with older 3300 systems and standard API 670 specifications.

-

ClickLoc™ Connectors: Secure, reliable, and easy to connect in high-vibration environments.

-

Robust Construction: Built to withstand extreme temperatures, corrosive environments, and mechanical stress.

-

High Precision: Delivers accurate non-contact measurement with exceptional linearity and repeatability.

-

EMI/RFI Immunity: Superior shielding ensures accurate data even in noisy industrial conditions.

-

Ease of Installation: Threaded or clamp mount options simplify field deployment and maintenance.

-

Extended Operating Range: Supports wide temperature and environmental conditions.

-

Sealed Housing: Moisture and dust ingress protection ensures long service life.

FAQ (Frequently Asked Questions)

-

How does the 330103-00-03-10-02-05 proximity probe detect shaft movement?

It operates on the principle of eddy current sensing, where changes in the distance between the probe tip and a conductive shaft surface alter the electrical signal, providing real-time measurement of shaft vibration or displacement. -

What makes this proximity probe suitable for critical machinery monitoring?

The 3300 XL 8mm probe offers high sensitivity, robust RFI shielding, and exceptional durability under harsh industrial conditions, ensuring reliable data for protection and diagnostic systems in turbines, compressors, and other rotating machinery. -

Can the probe be used in explosive or hazardous environments?

Yes, depending on system configuration and associated proximitor modules, the probe can be certified for use in ATEX, CSA, or IECEx classified areas. Always verify certification requirements before deployment. -

What type of maintenance is required for this proximity probe?

Routine visual inspection, checking signal integrity, and verifying mounting tightness are recommended. The probe itself requires minimal maintenance unless subjected to mechanical damage or extreme contamination. -

What are the consequences of installing a probe too close or too far from the shaft surface?

Improper gap settings can result in inaccurate readings, loss of linear response, or system fault conditions. Installation should always follow manufacturer-recommended target gaps, typically around 2 mm for optimal performance. -

How is the 330103 probe calibrated?

Calibration is factory-performed and designed to be consistent across systems. However, system calibration can be verified in the field using a micrometer and corresponding signal output to ensure linearity and correct scale factors. -

Can this probe operate continuously at high temperatures?

Yes, it supports continuous operation up to +177°C (+350°F), making it ideal for applications with high ambient or process temperatures such as gas turbines or steam environments. -

What precautions should be taken during installation in high-vibration zones?

Proper cable strain relief, secure mounting with locking compound, and vibration-isolated routing of extension cables are essential to avoid loosening or signal degradation over time. -

What kind of output signal does this probe generate?

The probe generates a voltage output proportional to the distance from the target surface, typically at a scale of 200 mV/mil (7.87 mV/μm), used by proximitor modules for processing. -

Is the probe affected by surface finish or material of the monitored shaft?

Yes, while it is calibrated for standard steel targets, variations in conductivity or surface roughness may slightly affect sensitivity. It is recommended to maintain clean, smooth, and uniform shaft surfaces for consistent measurements.

Related Models from the Same Series

| Model Number | Description | Cable Length | Connector Type |

|---|---|---|---|

| 330103-00-12-10-02-05 | 3300 XL 8mm Probe with 12 ft Cable | 12 ft | ClickLoc™ |

| 330103-00-05-10-02-05 | 3300 XL 8mm Probe with 5 ft Cable | 5 ft | ClickLoc™ |

| 330104-00-05-10-02-00 | Reverse Mount Probe for tight space access | 5 ft | Radial Mount |

| 330106-05-30-10-02-00 | High-temperature 8mm Probe | 30 ft | Flameproof version |

| 330180-91-05 | Extension Cable for 3300 XL Series | 5 m | Dual-ended ClickLoc™ |

| 330130-040-00 | Proximitor Sensor | – | – |

Popular Bently Nevada Models

| Model Number | Description | Application | Key Feature |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | Data Acquisition System | Monitors dynamic events |

| 3500/42M | Vibration Monitor Module | General Vibration Monitoring | 4-channel monitoring |

| 3500/05 | System Rack for 3500 Series | System Integration | Holds up to 14 modules |

| 190501-00-08 | Velomitor Piezoelectric Velocity Sensor | Machine Vibration Monitoring | Low-frequency detection |

| 330400 | Proximitor Sensor for 5mm/8mm Probes | Signal Conditioning | For narrow space applications |

| 990-08-XX-01-00 | Keyphasor Module | Rotational Speed Monitoring | Phase reference signal detection |

Excellent PLC

Excellent PLC