| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

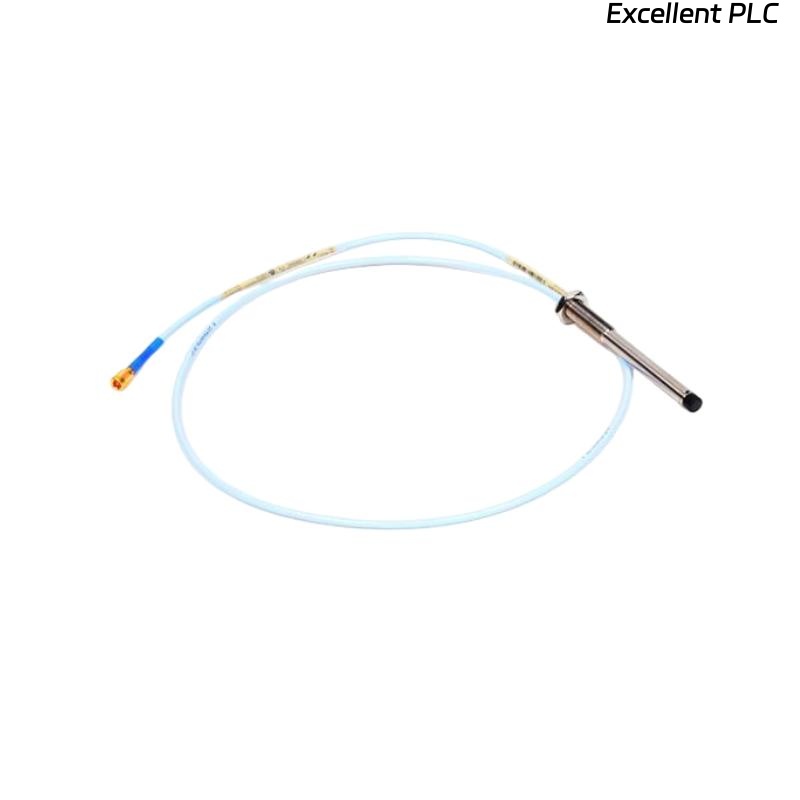

The Bently Nevada 330103-00-03-10-02-R0 is an advanced 8 mm proximity probe from the 3300 XL series, designed for high-precision vibration and position monitoring in rotating machinery. It offers exceptional accuracy, durability, and ease of integration, making it ideal for critical applications in industries such as power generation, oil & gas, and manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 330103-00-03-10-02-R0 |

| Thread Type | M10 x 1 |

| Measurement Range | 8 mm |

| Overall Case Length | 30 mm |

| Total Length | 1.0 meter (3.3 feet) |

| Connector Type | Miniature coaxial ClickLoc connector |

| Cable Type | Standard cable |

| Sensitivity | 0.5 V/mm |

| Frequency Response | 0–10 kHz |

| Probe Case Material | AISI 303 or 304 stainless steel |

| Weight | 0.323 kg |

Applications

-

Vibration Monitoring: Detects radial and axial vibrations in rotating machinery to prevent failures.

-

Shaft Position Measurement: Measures the position of shafts to ensure proper alignment and operation.

-

Keyphasor® and Speed Measurement: Provides accurate timing signals for synchronization and control systems.

-

API 670 Compliance: Meets the standards set by the American Petroleum Institute for machinery protection systems.

Product Advantages

-

High Accuracy: Provides precise measurements for critical machinery monitoring.

-

Interchangeability: Components are interchangeable without the need for individual calibration.

-

API 670 Compliance: Fully compliant with industry standards for machinery protection.

-

Robust Design: Built to withstand harsh industrial environments.

-

Easy Integration: Compatible with existing Bently Nevada systems and accessories.

FAQ

Q1: How do I properly install the 330103-00-03-10-02-R0 probe to ensure accurate measurements?

A1: Ensure the probe is securely mounted perpendicular to the shaft, maintaining the recommended gap. Avoid placing the probe near sources of electromagnetic interference.

Q2: Can this probe be used with other 3300 XL series monitoring systems?

A2: Yes, it is fully compatible with all standard 3300 XL series modules and monitoring systems.

Q3: What are the best practices for cable routing to minimize signal noise?

A3: Keep probe cables away from high-voltage lines and rotating machinery. Use shielded cable and maintain tight connectors.

Q4: How can I verify the probe is functioning correctly after installation?

A4: Use the system’s built-in self-test and check for proper Keyphasor® pulse output and vibration signal readings.

Q5: Is this probe suitable for high-speed rotating machinery?

A5: Yes, it is designed for high-speed applications up to the rated shaft RPM specified by the 3300 XL series.

Q6: How do I handle alignment issues between probe and shaft?

A6: Adjust the probe to ensure the sensing tip is centered and parallel to the shaft. Use the recommended feeler gauges for initial setup.

Q7: Can the probe operate in environments with moderate dust or moisture?

A7: Yes, the probe has a robust industrial design but avoid submerging it or exposing it to corrosive chemicals.

Q8: How do I detect a failing probe before it impacts machinery monitoring?

A8: Monitor signal consistency and Keyphasor® pulses. Anomalies like signal dropouts or excessive noise indicate potential probe issues.

Q9: Can this probe be replaced without recalibrating the monitoring system?

A9: Yes, as part of the 3300 XL series, it is interchangeable without individual recalibration.

Q10: What troubleshooting steps are recommended if vibration readings seem inaccurate?

A10: Check the gap between probe and shaft, ensure cables are correctly connected, verify system settings, and rule out electrical interference.

Recommended Models (Same Series or Related)

| Model | Description |

|---|---|

| 330101-00-03-10-02-R0 | Standard 8 mm probe with M10 x 1 thread |

| 330102-00-03-10-02-R0 | 8 mm probe with armor, M10 x 1 thread |

| 330104-00-03-10-02-R0 | 8 mm probe with armor, M10 x 1 thread, extended temperature range |

| 330140-00-03-10-02-R0 | Smooth case 8 mm probe, M10 x 1 thread |

| 330191-00-03-10-02-R0 | Extended temperature range 8 mm probe |

| 330103-00-03-10-02-R0 | 10 mm probe, M10 x 1 thread |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330104-00-07-05-01-05 | Standard industrial module for reliable system operation |

| 330104-00-10-05-01-00 | High-capacity module for enhanced data processing |

| 330104-00-12-05-01-03 | Redundant module for critical applications |

| 330104-00-15-05-01-02 | High-speed module for real-time control |

| 330104-00-18-05-01-01 | Multi-protocol module for flexible integration |

| 330104-00-20-05-01-04 | Compact, low-power module for energy-efficient operation |

Excellent PLC

Excellent PLC