| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

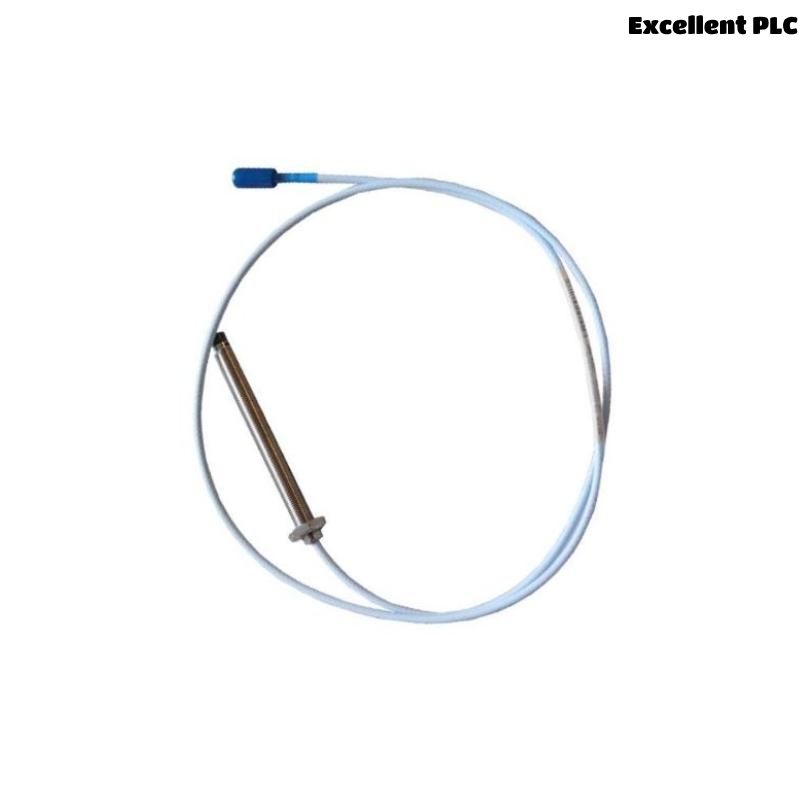

The Bently Nevada 330103-00-03-20-02-00 is a precision 8 mm Proximity Probe from the trusted 3300 XL series, engineered for high-fidelity vibration and shaft position monitoring in rotating machinery. This probe is part of the proven condition monitoring system widely deployed in critical industrial environments to detect shaft displacement and vibration patterns, enabling early fault detection and predictive maintenance.

Built for reliability and accuracy, the probe delivers robust performance under severe operating conditions including temperature extremes, mechanical shocks, and corrosive environments. It is optimized for use with the Bently Nevada 3300 XL monitoring system, ensuring seamless integration and consistent data output.

Key Features

-

8 mm probe diameter for precise proximity sensing

-

Compatible with Bently Nevada 3300 XL series monitoring systems

-

High sensitivity and wide frequency response for accurate vibration measurement

-

Constructed for extreme temperature and harsh industrial environments

-

Durable stainless steel probe body with ruggedized cable assembly

-

Supports continuous real-time monitoring of shaft position and vibration

-

Resistant to mechanical shock and vibration (100 g shock tolerance)

-

Easy installation with industry-standard connectors and mounting options

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | 330103-00-03-20-02-00 |

| Product Line | 3300 XL |

| Probe Diameter | 8 mm |

| Sensing Method | Eddy current proximity sensing |

| Measurement Range | 0 to 127 mils (0 to 3.2 mm) typical |

| Frequency Response | DC to 20 kHz |

| Operating Temperature | -40°C to +121°C (standard) |

| Cable Length | Customizable; standard options available |

| Connector Type | MIL-C-5015 or equivalent industrial connector |

| Cable Type | Shielded coaxial cable |

| Probe Material | Stainless steel probe tip with ruggedized cable |

| Vibration Resistance | Up to 30 g (10–2000 Hz) |

| Shock Resistance | 100 g, 11 ms half sine pulse |

| Weight | 0.646 kg |

| Dimensions | Total Length : 2.0 meters |

| Mounting Options | Threaded or welded mounting available |

Industry Applications

This proximity probe is widely utilized across industries requiring precision monitoring of rotating equipment:

-

Power Generation – Turbine shaft monitoring and generator condition diagnostics

-

Oil & Gas – Compressor and pump shaft vibration and position sensing

-

Mining & Metals – Critical machinery vibration monitoring

-

Chemical Processing – Reactor agitator shaft monitoring

-

Pulp & Paper – Rotating equipment vibration monitoring

-

Marine & Offshore – Propulsion shaft and auxiliary machinery condition monitoring

Product Advantages

-

Ensures accurate and reliable shaft displacement measurement

-

Robust design for operation under extreme temperature and mechanical stresses

-

Enables early fault detection to prevent costly unplanned downtime

-

Seamless integration with the trusted Bently Nevada 3300 XL monitoring platform

-

Long operational life with minimal maintenance requirements

-

Designed for easy installation and compatibility with standard system components

-

Built to withstand harsh industrial environments

Frequently Asked Questions (FAQ)

1. What type of signal output does this probe provide?

It outputs an analog voltage signal proportional to shaft proximity.

2. Is this probe compatible with all Bently Nevada monitors?

It is designed specifically for the 3300 XL series monitoring systems.

3. What standard cable lengths are available?

Standard cable lengths are offered; custom lengths can be requested.

4. What is the maximum operating temperature?

Rated for operation up to 121°C (250°F).

5. How is the probe mounted?

Supports threaded or welded mounting configurations.

6. How does it withstand harsh environments?

The probe uses stainless steel construction and ruggedized cabling for durability.

7. Can it be used to measure shaft speed?

Yes, indirectly by analyzing vibration frequency signals.

8. What is the probe’s diameter?

The diameter is 8 mm, balancing precision and mechanical strength.

9. Is the probe resistant to shock and vibration?

Yes, designed to withstand 100 g shock and high vibration levels.

10. What is the expected service life?

Typically, the probe provides years of reliable service in industrial conditions.

Related Bently Nevada 3300 XL Proximity Probes

| Model Number | Description |

|---|---|

| 330103-00-03-10-01-00 | 8 mm Proximity Probe standard version |

| 330103-00-05-05-01-05 | 8 mm Proximity Probe, high temperature |

| 330103-00-05-10-02-05 | 8 mm Proximity Probe, extended range |

| 330103-00-10-10-01-00 | 8 mm Proximity Probe ruggedized version |

| 330103-00-12-05-01-05 | 8 mm Proximity Probe stainless steel |

| 330103-00-16-10-02-05 | 8 mm Proximity Probe with special cable |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/33-02-00 | 16-Channel Relay Module |

| 3500/40M-01-00 | Proximitor Monitor |

| 3500/62 | Isolation I/O Modules |

| 3500/65-01-00 | 16-Channel Temperature Monitor |

| 990-04-XX-01 | 990 Vibration Transmitter |

| 84661-10 | Velomitor Interconnect Cable |

Excellent PLC

Excellent PLC

.jpg)