| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

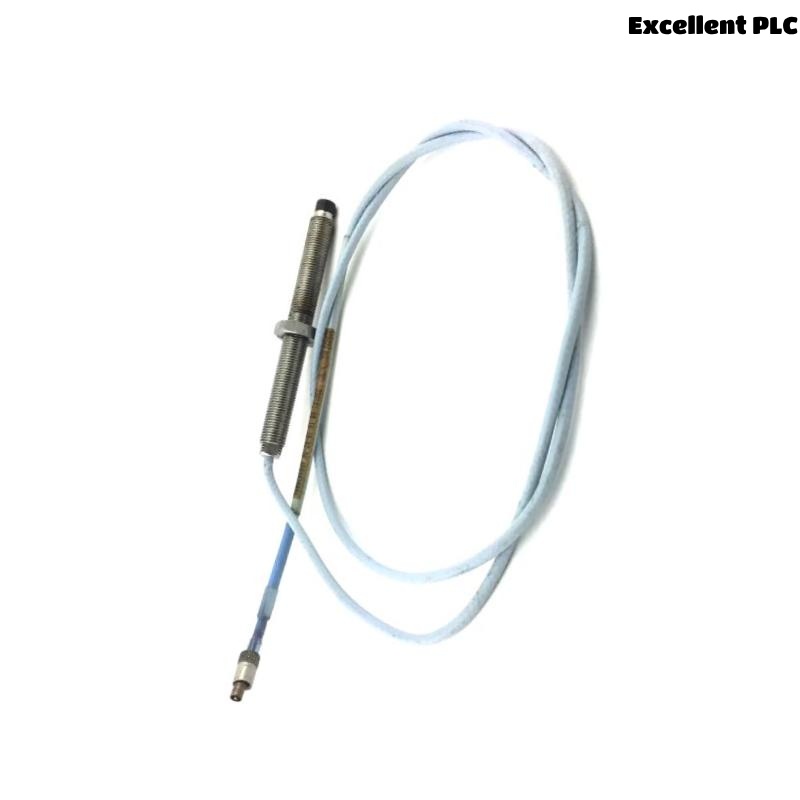

The Bently Nevada 330103-00-04-50-11-00 is a premium-quality 3300 XL 8 mm proximity probe, specifically engineered for critical machine condition monitoring and protection in demanding industrial applications. This non-contact sensor detects shaft displacement and vibration by measuring the distance between the probe tip and a conductive target (typically the rotating shaft), helping detect conditions like imbalance, misalignment, and bearing wear.

The “50” in the model number denotes a 50-mil (1.27 mm) linear range, while the “11” configuration code typically indicates specific physical or environmental configuration details such as reverse orientation or connector style, depending on the system architecture.

This model is ideal for integration into Bently Nevada’s 3300 XL system and legacy 3300 platforms.

Key Features

-

Precision eddy current sensing technology

-

8 mm probe tip suitable for standard clearance measurement

-

Calibrated for a 50-mil (1.27 mm) linear measurement range

-

High reliability in extreme industrial environments

-

Fully compatible with 3300 XL extension cables and Proximitor sensors

-

Threaded stainless steel body (M16 × 1.5 mm) for secure installation

-

Shielded design for reduced electromagnetic interference

-

Proven performance in continuous monitoring applications

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330103-00-04-50-11-00 |

| Product Series | Bently Nevada 3300 XL |

| Tip Diameter | 8 mm |

| Linear Range | 1.27 mm (0.050 in / 50 mils) |

| Sensing Range | 0.25 mm to 2.54 mm (0.010 in to 0.100 in) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) nominal |

| System Accuracy | ±0.07 mm (±0.0028 in) over linear range |

| Output Signal Type | Voltage proportional to distance (gap) |

| Mounting Thread | M16 × 1.5 mm |

| Connector Type | 10-pin Bendix-style male connector |

| Cable Length | 10 meters (32.8 ft), part of integrated assembly |

| Probe Body Material | Stainless Steel |

| Operating Temperature | -40 °C to +120 °C |

| Storage Temperature | -51 °C to +177 °C |

| Vibration Resistance | 20 g, 10–2000 Hz |

| Shock Limit | 500 g peak |

| Environmental Protection | IP65 (when properly installed) |

| Dimensions | Total Length: 5.0 meters |

| Weight | 1.615 kg |

Typical Applications

-

Shaft vibration monitoring in turbines, compressors, motors

-

Axial thrust position monitoring in high-speed rotating equipment

-

Bearing wear detection in pumps and critical process machines

-

Real-time condition monitoring in oil & gas, petrochemical, and power generation sectors

-

Machinery protection systems using Bently Nevada 3300 XL or 3500 platforms

-

Condition-based maintenance (CBM) and predictive diagnostics

-

Installations requiring extended linear range beyond standard 40 mils

Advantages

-

Extended Linear Range: Accurate measurement up to 50 mils for greater flexibility in system design

-

High Durability: Built to withstand extreme conditions including temperature fluctuations, shock, and vibration

-

System Compatibility: Seamlessly integrates with existing 3300 and 3500 Bently Nevada systems

-

Reliable Output: Stable signal output even in high electromagnetic interference (EMI) environments

-

Field Replaceable: Modular design simplifies maintenance and reduces downtime

-

Trusted Technology: Backed by decades of industry use and field-proven reliability

-

Flexible Mounting: Threaded body and cable configurations support diverse mechanical layouts

-

Zero Mechanical Contact: Non-contact design eliminates wear and prolongs operational life

Frequently Asked Questions (FAQ)

-

What does the “50” in the model number signify?

It indicates the linear measurement range of the probe: 50 mils (1.27 mm). -

What is the meaning of “11-00” in the part number?

It typically refers to specific configuration settings like connector orientation or environmental sealing; refer to OEM documentation for exact meaning. -

Is this probe compatible with 3300 XL Proximitor sensors?

Yes, it is fully compatible with 3300 XL extension cables and Proximitor sensors. -

Can the probe be used in high-vibration environments?

Yes, it’s designed to handle up to 20 g vibration and 500 g shock. -

Is the cable length fixed?

This model comes with a 10-meter cable, but other lengths may be available upon request. -

Does it require special installation tools?

Standard thread-based mounting tools are sufficient. Bently Nevada provides optional alignment tools. -

Can this be used in explosive or hazardous areas?

Use in hazardous environments depends on overall system certification and installation methods. -

What is the signal output type?

The probe produces an analog voltage signal proportional to the gap between the probe and target surface. -

What’s the probe’s body material?

Stainless steel, providing excellent corrosion resistance and mechanical strength. -

Is this model suitable for legacy Bently Nevada systems?

Yes, the 3300 XL probes are backward compatible with earlier 3300 systems.

Related and Recommended Models

| Model Number | Description |

|---|---|

| 330103-00-04-50-02-05 | Standard 50 mil 8 mm XL Probe (Bendix connector) |

| 330103-00-04-20-02-05 | 20 mil range 8 mm Probe, standard version |

| 330104-00-05-10-01-00 | Armored cable 8 mm Proximity Probe |

| 330101-00-14-10-02-05 | High-temperature 8 mm Probe |

| 330130-040-00-00 | 4-meter XL Extension Cable |

| 330180-91-05 | 3300 XL Proximitor Sensor |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/42M | Proximitor Vibration Monitor |

| 3500/22M | TDI with Buffered Output |

| 3300 XL Proximitor Sensor | Sensor for XL 8 mm and 5 mm probes |

| 7200 Series | Legacy Proximitor and Vibration Transducers |

| 990-04-70-01-00 | General Purpose Velocity Transducer |

| 3500/15 | Power Supply Module for 3500 System |

Excellent PLC

Excellent PLC