| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

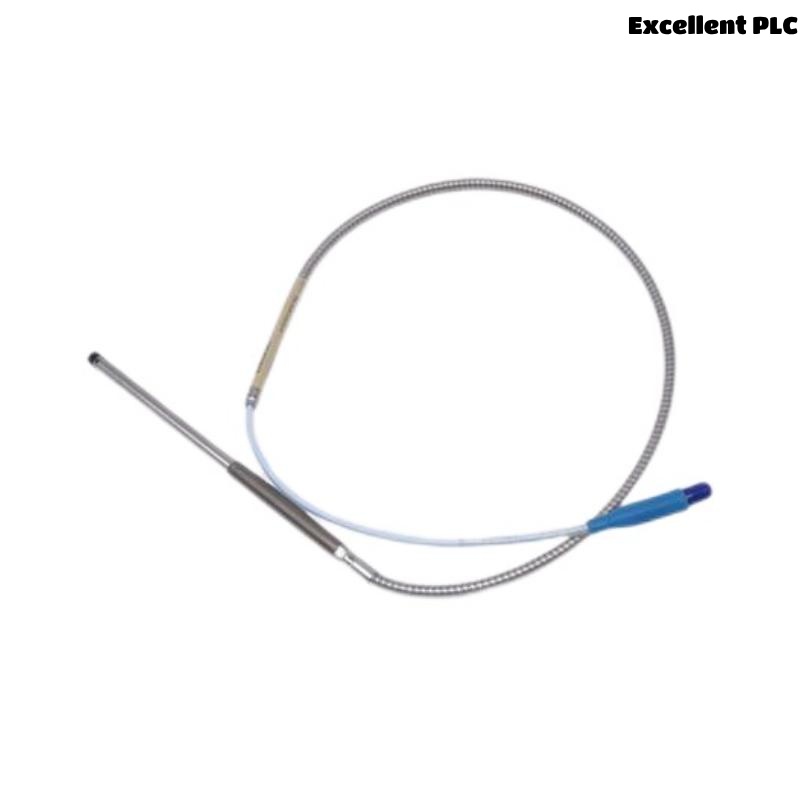

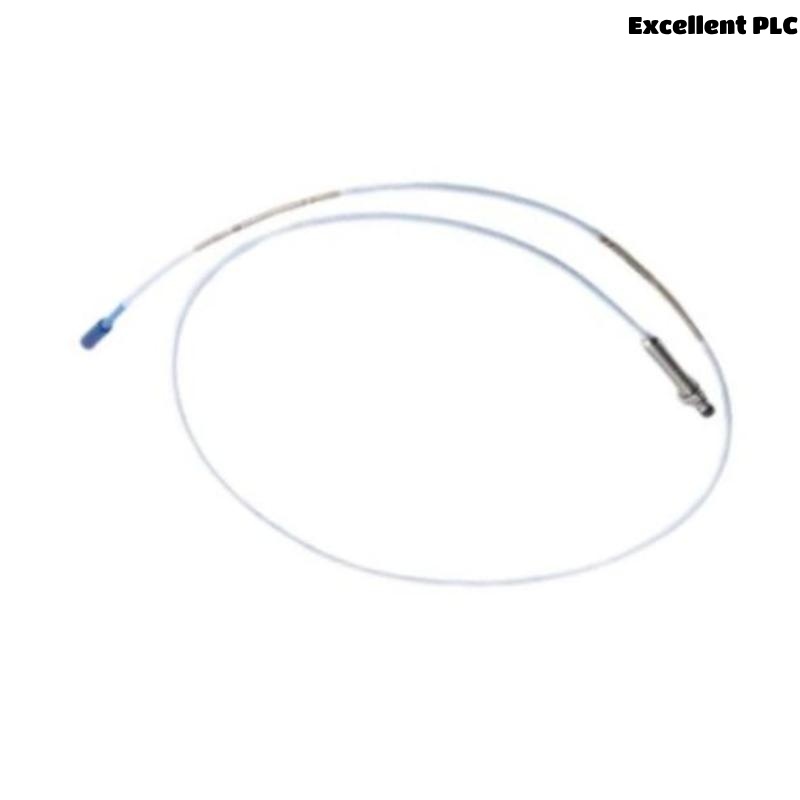

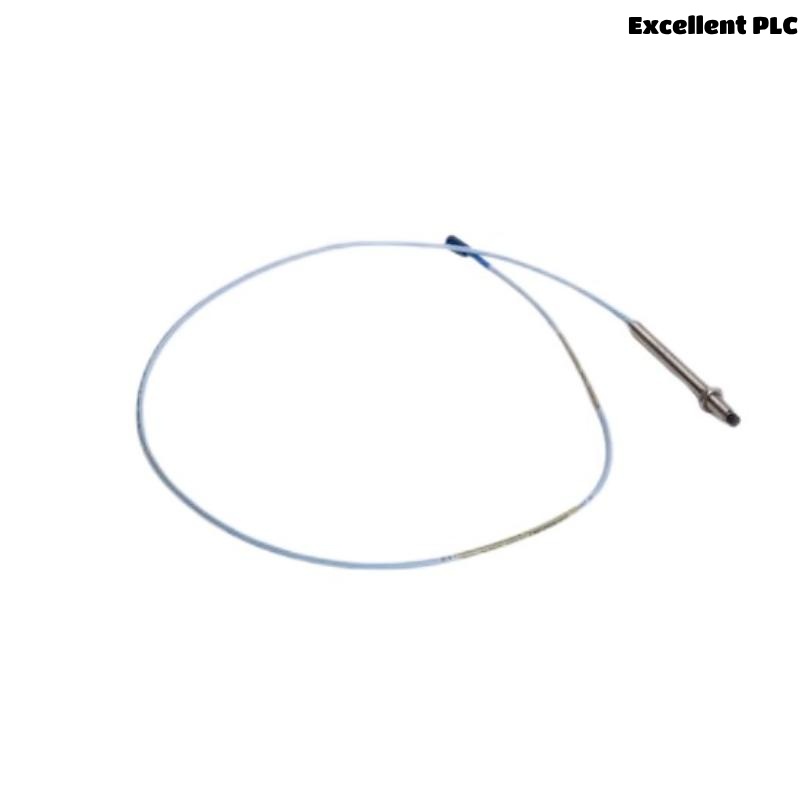

The Bently Nevada 330103-00-05-15-01-00 3300 XL 8 mm Proximity Probe is part of the high-performance 3300 XL series, engineered by Bently Nevada for accurate, stable, and durable condition monitoring of rotating machinery. Designed for rugged industrial environments, this model provides precise non-contact measurement of shaft displacement, vibration, and position.

This specific configuration features an 8 mm probe tip diameter, a 5-meter integral cable, and a straight connector. The mounting thread is 5/8-18 UNF, which allows for deeper insertion applications or compatibility with specific probe brackets. It offers robust protection against contamination and extreme temperatures, making it ideal for long-term deployment in mission-critical assets.

Key Features

-

8 mm diameter tip ensures stable displacement measurements

-

5/8-18 UNF thread suitable for standard or deeper mounting depths

-

Straight connector with durable coaxial design

-

5-meter integral cable for extended reach

-

High temperature tolerance and vibration resistance

-

Compatible with 3300 XL extension cables and Proximitor sensors

-

Excellent linearity and repeatability over extended operating ranges

-

Sealed for harsh environments (IP68 when properly installed)

-

Complies with API 670 industry standards for machinery protection

-

Part of a modular system for scalable machinery monitoring

Technical Specifications

| Item | Specification |

|---|---|

| Product Model | 330103-00-05-15-01-00 |

| Series | 3300 XL 8 mm |

| Probe Tip Diameter | 8 mm |

| Mounting Thread Size | 5/8-18 UNF-2A |

| Sensing Range | 2 mm (80 mils) |

| Linear Range | 0.25 to 2.0 mm (10 to 80 mils) |

| Connector Type | Straight coaxial connector |

| Connector Boot Orientation | Straight (0°) |

| Cable Length | 5 meters (integral) |

| Cable Type | Triaxial, low-noise, BNC-compatible |

| Probe Body Material | AISI 304 Stainless Steel |

| Operating Temperature | -35°C to +177°C (-31°F to +351°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +351°F) |

| Environmental Protection | IP68 (when properly installed and sealed) |

| Vibration Limit | 50 g peak, 10–2000 Hz |

| Shock Limit | 5000 g, 1 millisecond half-sine pulse |

| Insulation Resistance | >10⁹ ohms at 500 VDC |

| System Accuracy (Typical) | ±0.07 mm (±2.8 mils) |

| Compliance | API 670, CE |

| Dimensions | Total Length : 1.5 meters |

| Weight | 0.484 kg |

Industry Applications

The 330103-00-05-15-01-00 proximity probe is widely adopted across sectors that demand continuous, high-precision monitoring of rotating equipment:

-

Petrochemical Plants – Monitoring compressors and turbines

-

Power Generation – Steam and gas turbine shaft displacement detection

-

Oil & Gas Upstream – Pumpjack and drilling equipment integrity

-

Marine Engineering – Marine propulsion and shaft machinery monitoring

-

Mining and Heavy Industry – Crushers, mills, and gearboxes

-

Pulp & Paper Manufacturing – High-speed roller and calendar shaft monitoring

-

Aerospace Ground Testing – Jet engine rotation behavior analysis

-

Pharmaceutical Manufacturing – Sensitive mixer and reactor vibration analysis

Product Advantages

-

Extended Thread Length: Allows deeper or flexible mounting in larger bearing housings or custom assemblies

-

Straight Connector Design: Suitable for installation in open or vertically-aligned machinery spaces

-

Field Proven Durability: Designed for years of use under severe mechanical and environmental stress

-

Plug-and-Play Compatibility: Seamless integration with Bently Nevada 3300 XL systems

-

Accurate at High Speeds: Maintains signal clarity even in high-speed rotating shafts

-

No Contact Wear: Non-contact sensing eliminates physical degradation, ensuring longevity

-

Factory Calibrated: Delivers ready-to-use performance with no on-site calibration required

-

EMI Shielded: Low-noise coaxial construction resists signal interference

-

High Reliability in Dirty Environments: Resists oil, grease, and metal debris

-

Global Standard Compliance: Meets industry certifications, including API 670 and CE

Frequently Asked Questions (FAQ)

-

What does the part number 330103-00-05-15-01-00 represent?

It identifies a 3300 XL series 8 mm probe with 5 m cable, 5/8-18 thread, and a straight connector. -

Is this probe compatible with all Bently Nevada proximitor modules?

Yes, it is compatible with all standard 3300 XL Proximitor Sensors. -

What applications benefit most from the 5/8-18 UNF thread?

It’s best suited for equipment requiring deeper mounting or larger bore insertion. -

Does the probe require calibration after installation?

No, it is factory-calibrated. Periodic verification is recommended during scheduled maintenance. -

Can the probe operate in high humidity or submerged conditions?

Yes, when properly sealed, the unit complies with IP68 standards. -

What is the bend radius for the integral cable?

A minimum bend radius of 25 mm is recommended for long-term cable integrity. -

How does the straight connector compare with angled designs?

Straight connectors are optimal in open spaces, while angled connectors are used for tight or side-entry installations. -

Is this probe suitable for turbine applications?

Absolutely, it is widely used in steam and gas turbine condition monitoring. -

Can this probe be paired with extension cables of different lengths?

Yes, it works with compatible Bently Nevada extension cables of 5 m, 7 m, or 9 m. -

What is the expected service life of this proximity probe?

In standard conditions, the service life exceeds 5–10 years with proper installation.

Related Models

| Model Number | Description |

|---|---|

| 330103-00-05-10-01 | 8 mm Probe, 5 m cable, 3/8-24 thread, straight boot |

| 330103-00-05-10-12-00 | 8 mm Probe, 5 m cable, 3/8-24 thread, 90° boot |

| 330103-00-05-15-12-00 | 8 mm Probe, 5 m cable, 5/8-18 thread, 90° boot |

| 330103-00-06-15-01-00 | 8 mm Probe, 6 m cable, 5/8-18 thread, straight connector |

| 330103-00-08-15-01-00 | 8 mm Probe, 8 m cable, 5/8-18 thread, straight connector |

| 330104-00-10-10-02 | 3300 XL Extension Cable, 10 m, straight connector |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/22M-01-01-00 | Transient Data Interface Module |

| 330104-00-05-10-02 | 3300 XL Extension Cable, 5 m, straight connector |

| 330130-045-01-00 | Standard Extension Cable, 4.5 m |

| 330180-91-05 | Proximitor Sensor for 8 mm probes, 5 m cable |

| 3500/42M-01-00 | Vibration Monitor Module for Accelerometers and Probes |

| 1900/65A-00-01-01 | Compact Machine Monitor for General Purpose Applications |

Excellent PLC

Excellent PLC