| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

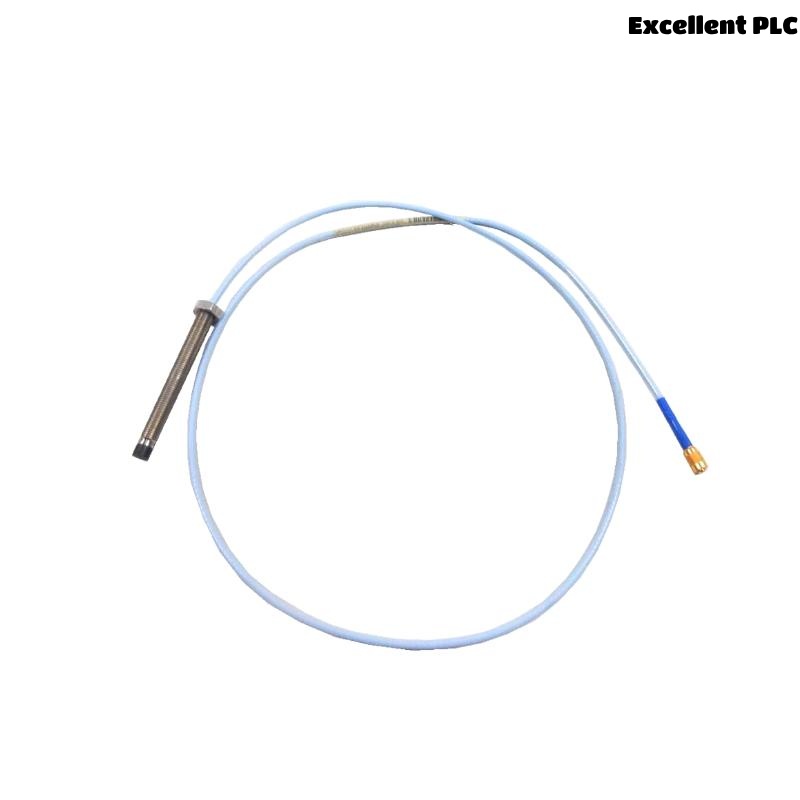

The Bently Nevada 330103-00-06-05-02-IN 8 mm Proximity Probe is an advanced sensor used in vibration monitoring systems to measure the proximity between a probe tip and a rotating machine part. Part of the 3300 XL Series, this probe is designed to provide highly accurate and reliable measurements of machine displacement and vibration in real-time. The probe operates based on eddy current principles, which ensures that it can provide precise data even in harsh industrial environments.

This proximity probe is widely used in industries such as power generation, oil and gas, and manufacturing, where early detection of vibration problems is crucial to avoid machine failures and downtime. Its design offers easy integration with vibration monitoring systems and is capable of providing valuable insights into machine health, enabling predictive maintenance strategies.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330103-00-06-05-02-IN |

| Type | 8 mm Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Shaft Diameter | 8 mm |

| Operating Temperature | -40°C to +120°C |

| Range | 1-25 mil (0.0254-0.635 mm) |

| Mounting Type | Direct Mount |

| Measurement Principle | Eddy Current |

| Cable Length | 0.5 meter |

| Accuracy | ± 0.001 inch (± 0.0254 mm) |

Product Applications

The Bently Nevada 330103-00-06-05-02-IN 8 mm Proximity Probe is used in various applications for vibration monitoring and condition-based monitoring of machinery. Some of its primary uses include:

-

Rotating Equipment Monitoring: The probe is essential in monitoring the displacement and vibration of rotating machinery such as motors, compressors, turbines, and pumps, helping identify any imbalance, misalignment, or other faults.

-

Power Generation: Commonly used in power plants to monitor critical equipment like gas turbines, steam turbines, and generators, where accurate vibration data is vital to prevent damage to machinery.

-

Oil and Gas Industry: Used in oil rigs and refineries, where maintaining the health of rotating equipment like pumps and compressors is critical to ensure continuous operation and prevent failures.

-

Manufacturing: The probe is applied in various manufacturing facilities to monitor the condition of motors and conveyors, ensuring the smooth operation of production lines.

-

Aerospace: Used in aerospace applications to monitor the health of engine components and other critical systems, ensuring safety and efficiency.

-

Marine Industry: Helps in monitoring the health of ship engines and machinery, enabling early detection of faults that could lead to downtime or operational disruptions.

Product Advantages

-

High Accuracy: The 330103-00-06-05-02-IN probe offers high-precision measurement, with an accuracy of ± 0.001 inch (± 0.0254 mm), which ensures highly reliable data for machine condition monitoring.

-

Rugged Design: Designed to withstand harsh industrial environments, the probe operates effectively even under extreme conditions, including high temperatures (up to 120°C) and vibration.

-

Long Cable Length: With a total cable length of 0.5 meters, it provides sufficient flexibility for installation in various types of machinery, offering ease of access in challenging environments.

-

Wide Range of Applications: Its versatile 8 mm shaft diameter allows it to be used across a wide range of industrial applications, making it ideal for monitoring multiple types of rotating equipment.

-

Real-Time Monitoring: The proximity probe provides real-time displacement measurements, enabling quick identification of potential issues before they develop into major problems, thus enhancing operational efficiency.

-

Integration with Monitoring Systems: This probe seamlessly integrates with the Bently Nevada 3300 XL vibration monitoring system, allowing users to easily incorporate it into existing monitoring setups.

-

Durability and Longevity: Constructed for durability, the probe’s components are designed to withstand high operational loads and challenging industrial conditions, reducing the need for frequent replacements.

-

Non-contact Measurement: The eddy current principle allows for non-contact measurement, minimizing wear and tear on the probe and ensuring longer operational lifetimes.

-

Predictive Maintenance: By providing accurate and reliable vibration data, this probe supports predictive maintenance strategies, helping prevent unplanned downtime and costly repairs.

-

Cost-Effective Solution: The Bently Nevada 330103-00-06-05-02-IN probe offers a cost-effective solution for vibration monitoring, providing significant value in terms of preventing machinery failures and improving system uptime.

Frequently Asked Questions (FAQ)

Q1: What is the measurement principle of the 330103-00-06-05-02-IN probe?

A1: The 330103-00-06-05-02-IN probe operates based on the eddy current measurement principle, which is used to detect changes in the proximity of a metallic target.

Q2: What is the range of the Bently Nevada 330103-00-06-05-02-IN probe?

A2: The probe can measure displacement in the range of 1-25 mil (0.0254-0.635 mm).

Q3: What is the shaft diameter of the proximity probe?

A3: The probe has a shaft diameter of 8 mm, making it suitable for a wide range of industrial applications.

Q4: How accurate is the 330103-00-06-05-02-IN probe?

A4: The probe offers an accuracy of ± 0.001 inch (± 0.0254 mm), ensuring high-precision measurements for reliable data collection.

Q5: What is the maximum operating temperature for this probe?

A5: The 330103-00-06-05-02-IN probe can operate in temperatures ranging from -40°C to +120°C.

Q6: What industries can benefit from using this proximity probe?

A6: The probe is commonly used in power generation, oil and gas, aerospace, manufacturing, and marine industries to monitor the condition of rotating machinery.

Q7: What is the weight of the 330103-00-06-05-02-IN probe?

A7: The probe weighs 0.161 kg, making it lightweight and easy to handle during installation.

Q8: How long is the cable that comes with the probe?

A8: The cable length of the 330103-00-06-05-02-IN probe is 0.5 meters, providing flexibility for installation in various setups.

Q9: Can the 330103-00-06-05-02-IN probe be used with other monitoring systems?

A9: The 330103-00-06-05-02-IN probe is designed to integrate seamlessly with Bently Nevada’s 3300 XL vibration monitoring system, but it can also be used with other compatible systems.

Q10: How does this probe help in predictive maintenance?

A10: The probe provides real-time vibration and displacement data, which helps identify potential issues early, enabling predictive maintenance strategies to avoid unexpected downtime.

Recommended Related Models (Same Series or Related)

| Model | Description | Range | Accuracy | Mounting |

|---|---|---|---|---|

| 330103-00-06-05-02-EX | Hazardous area 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-00-06-05-03-IN | 8 mm proximity probe for larger ranges | 1-50 mil (0.0254-1.27 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-00-06-05-04-IN | Extended length 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-00-06-05-02-IN | Standard 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-00-06-06-02-IN | 8 mm probe with custom cable length | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-00-06-07-02-IN | Extended range 8 mm proximity probe | 1-50 mil (0.0254-1.27 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

Recommended Popular Models from Bently Nevada

| Model Number | Parameters | Application | Advantages |

|---|---|---|---|

| 330103-00-06-05-02-00 | 24V, 10A, 2-wire | Vibration Monitoring | High accuracy, reliable performance |

| 330103-00-06-05-02-02 | 24V, 12A, 2-wire | Industrial Control | Durable, cost-effective, high efficiency |

| 330103-00-06-05-02-05 | 24V, 15A, 2-wire | Process Control Systems | High current capacity, stable operation |

| 330103-00-06-05-02-06 | 24V, 18A, 3-wire | Motor Control Systems | Versatile, efficient, robust design |

| 330103-00-06-05-02-07 | 24V, 20A, 2-wire | Automation Systems | Reliable, high precision |

| 330103-00-06-05-02-08 | 24V, 25A, 2-wire | Power Distribution Systems | High power capacity, long-lasting |

Excellent PLC

Excellent PLC