| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

The Bently Nevada 330103-00-06-10-02-00 is part of the 3300 XL 8mm Proximity Transducer System, designed specifically for machinery protection and condition monitoring applications. This proximity probe is widely recognized for its superior performance in monitoring shaft position and vibration in industrial rotating machinery, including turbines, compressors, pumps, and motors.

Featuring the proven eddy current sensing technology, the 3300 XL 8mm series provides accurate, stable, and reliable measurements in harsh environments. The product is fully compliant with API 670 specifications, making it an ideal choice for high-integrity applications where performance and reliability are paramount.

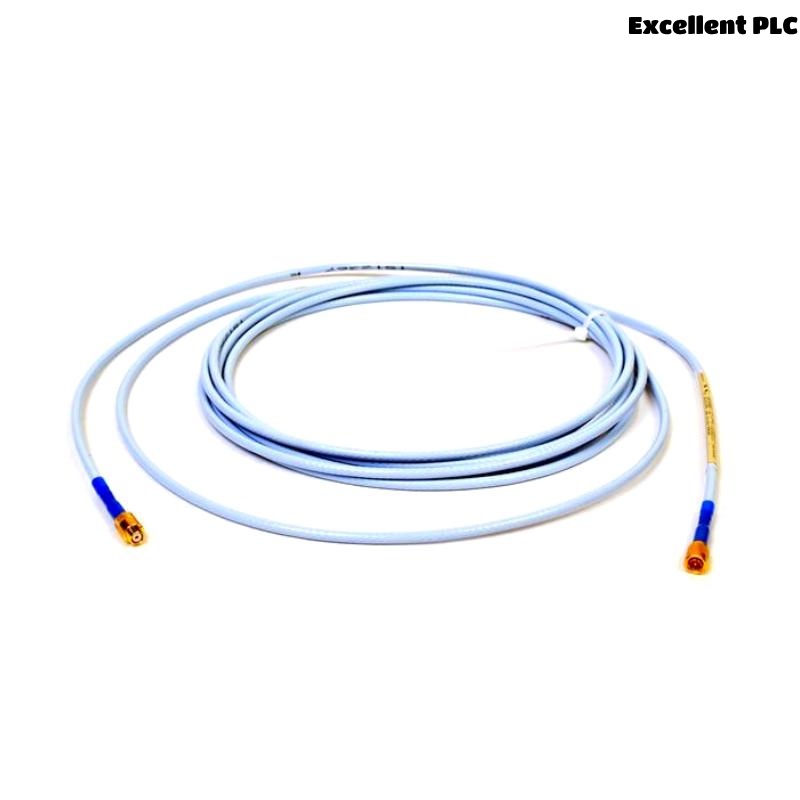

The probe system includes the proximity probe, extension cable, and Proximitor sensor, designed to operate together as a complete measurement chain. The 330103-00-06-10-02-00 variant is distinguished by its specific cable lengths and connector types, tailored for flexible configuration across a variety of installations.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330103-00-06-10-02-00 |

| Series | 3300 XL 8mm Proximity Transducer System |

| Sensing Technology | Eddy current |

| Probe Tip Diameter | 8 mm |

| Thread Size | 3/8-24 UNF-2A |

| Total Length | 1.0 meter |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 200 mV/mil (±5%) |

| Frequency Range | 0 to 10 kHz |

| Operating Temperature | -35°C to +177°C (-31°F to +351°F) |

| Pressure Rating | Up to 500 psi (34 bar) |

| Electrical Isolation | Yes, tip to case |

| Material | Probe tip: Polyphenylene Sulfide (PPS) |

| Connector Type | Miniature coaxial connector |

| Weight | 0.323 kg |

| Compliance | API 670 |

Product Applications

The Bently Nevada 3300 XL 8mm proximity probe system is utilized extensively across industries where precision machinery monitoring is critical. Common applications include:

-

Turbomachinery Monitoring

For real-time vibration and position measurements of shafts and rotors. -

Centrifugal and Reciprocating Compressors

Used for radial and axial displacement monitoring. -

Industrial Pumps

Ensures early detection of misalignment and bearing wear. -

Gas and Steam Turbines

Part of comprehensive machine protection systems. -

Motors and Generators

Facilitates condition-based maintenance strategies. -

Gearboxes

Helps detect early-stage faults in gear meshing and bearing conditions.

Product Advantages

-

API 670 Compliance

Meets the stringent criteria for safety and reliability in critical machinery protection. -

Robust Construction

Engineered to perform in high-temperature and high-pressure environments. -

Stable Calibration

Minimizes drift over time, providing long-term accuracy and reducing maintenance intervals. -

Interchangeability

Fully compatible with other 3300 XL system components, ensuring seamless integration. -

Wide Operating Temperature

Allows for versatile application in extreme industrial conditions. -

Eddy Current Accuracy

Delivers precise, non-contact measurements with minimal interference from contaminants. -

Industry Standard

Trusted by OEMs and maintenance teams worldwide for over two decades.

Frequently Asked Questions (FAQ)

-

What is the typical use of the 330103-00-06-10-02-00 proximity probe?

This model is primarily used for shaft vibration and position monitoring in critical rotating machinery. -

Is this probe compatible with older Bently Nevada systems?

Yes, it maintains backward compatibility with most 3300 systems, though specific integration should be verified. -

Can it be used in hazardous environments?

Yes, it is built with materials and designs suitable for use in explosive and hazardous areas, subject to appropriate certifications. -

How is the probe mounted?

The probe is typically threaded into a mounting sleeve or bracket near the monitored shaft. -

What makes the XL series different from older 7200 series probes?

The XL series offers improved electrical shielding, environmental protection, and extended temperature tolerance. -

Does the probe require recalibration over time?

It has excellent stability, but periodic validation is recommended, especially in mission-critical setups. -

What is the output of the system?

A voltage proportional to the distance between the probe tip and the target surface, typically 200 mV/mil. -

Can the system be field-assembled?

Yes, Bently Nevada offers field-installation kits for connectors and extension cables. -

How does it perform under high-pressure applications?

It is rated up to 500 psi, making it suitable for sealed machinery compartments. -

Is the probe affected by oil or contaminants?

No, the eddy current technology is non-contact and unaffected by most fluids and contaminants.

Related Models (Same Series)

| Model | Description | Tip Diameter | Cable Length |

|---|---|---|---|

| 330103-00-05-10-02-00 | 5 ft probe, 10 ft cable | 8 mm | 5 ft + 10 ft |

| 330103-00-08-10-02-00 | 8 ft probe, 10 ft cable | 8 mm | 8 ft + 10 ft |

| 330103-00-10-10-02-00 | 10 ft probe, 10 ft cable | 8 mm | 10 ft + 10 ft |

| 330104-00-06-10-02-00 | 8mm proximity probe with alternative connector | 8 mm | 6 ft + 10 ft |

| 330130-040-00-00 | Proximitor Sensor for 3300 XL series | — | — |

| 330180-91-05 | Extension cable for proximity probe | — | 5 meters |

Popular Models from Bently Nevada

| Model | Function | Category | Special Feature |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | Vibration Monitoring | High-speed data buffering |

| 3500/25 | Keyphasor Module | Keyphasor Signal Monitoring | Multiple Keyphasor channels |

| 3300 XL 11 mm | Proximity Probe | Proximity Detection | Extended range over 8 mm probe |

| 330104-00-05-10-02-00 | 3300 XL 8mm probe | Proximity Detection | Alternative length |

| 990-04-XX-01-00 | Velocity Sensor | Seismic Monitoring | Low-frequency measurement |

| 3701/55 | Vibration Monitor | Condition Monitoring | Compact DIN-rail form factor |

Excellent PLC

Excellent PLC