| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

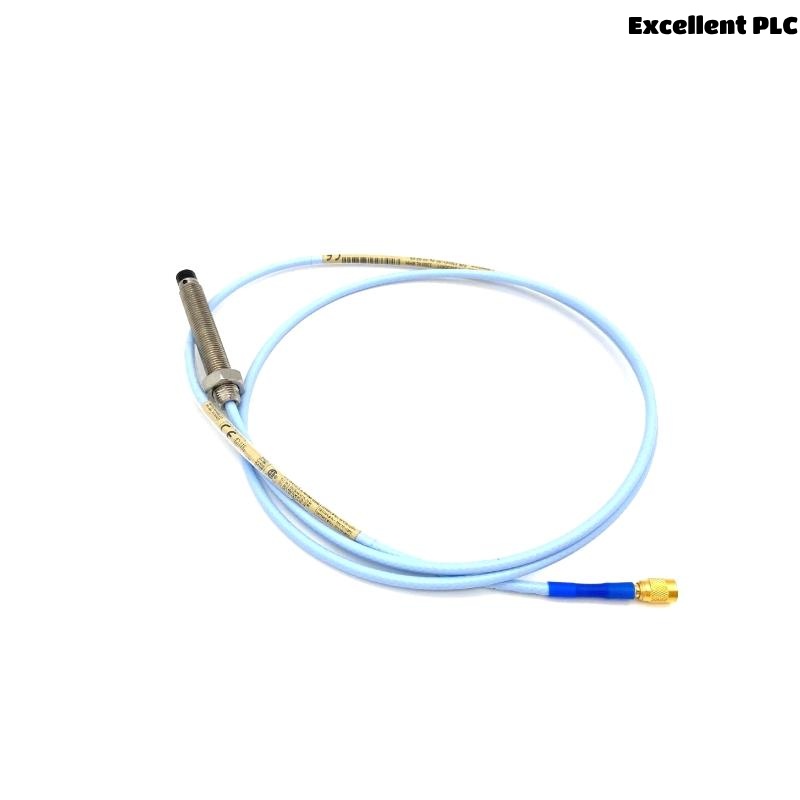

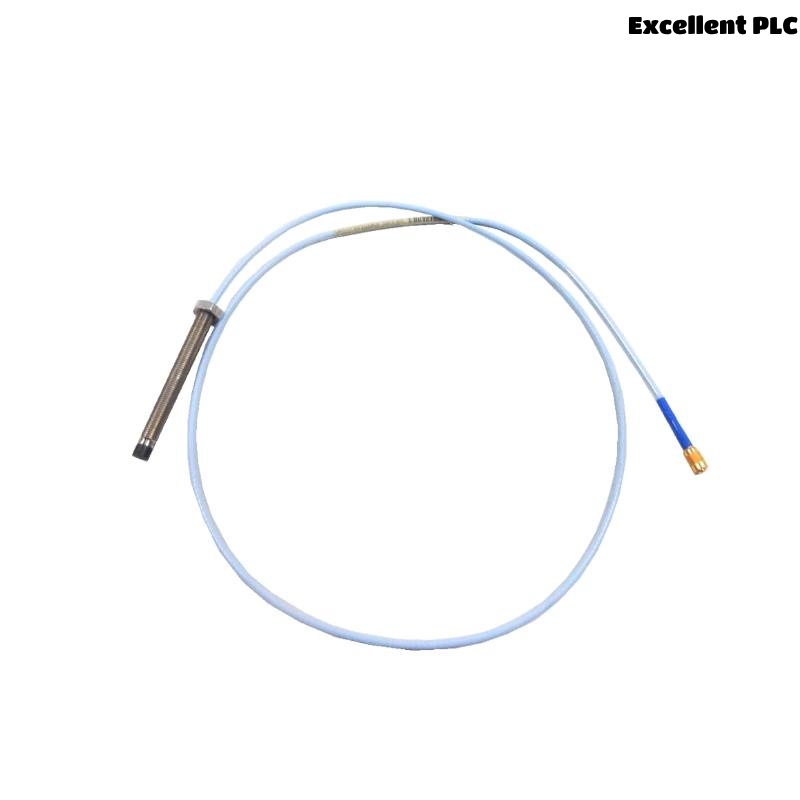

The Bently Nevada 330103-00-06-50-02-00 is a premium-grade proximity probe designed as part of the 3300 XL series, engineered for precision and reliability in vibration monitoring systems. This 8mm proximity probe serves as a critical component for non-contact shaft displacement and vibration measurement in rotating machinery. Built for industrial environments, the probe ensures accurate data collection to enable timely condition monitoring and predictive maintenance. With a robust design optimized for durability and operational stability, the 3300 XL proximity probes are trusted worldwide in critical asset monitoring applications.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330103-00-06-50-02-00 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Sensing Range | 8 mm |

| Tip Style | Potted tip with rugged housing |

| Cable Length | Typically customizable, standard |

| Operating Temperature | -40 °C to +121 °C (-40 °F to +250 °F) |

| Sensor Diameter | Approximately 8 mm |

| Total Length | 5 meters |

| Weight | 1.615 kg |

| Connector Type | MIL-C-26482 style connector or other options available |

| Housing Material | Stainless steel |

| Output Signal | AC voltage, proportional to gap |

| Mounting | Threaded or flange mounting options available |

Applications

The 3300 XL 8mm Proximity Probe is widely applied across multiple industries, particularly where monitoring of rotating equipment is critical:

-

Power Generation: Monitoring turbines, generators, and motors to detect shaft displacement and vibration anomalies.

-

Oil & Gas: Ensuring reliable operation of pumps, compressors, and gas turbines.

-

Aerospace: Vibration and shaft displacement monitoring in aircraft engines.

-

Manufacturing: Condition monitoring for high-speed rotating machinery like turbines and centrifugal pumps.

-

Marine: Monitoring propulsion systems and auxiliary machinery.

-

Pulp and Paper Industry: Machinery health monitoring to reduce downtime and improve maintenance scheduling.

-

Mining and Metals: Monitoring large motors, crushers, and mills for early fault detection.

Advantages

-

High Accuracy: The 3300 XL probe provides precise, consistent measurements essential for early fault detection.

-

Robust Design: Stainless steel housing and durable tip protect the sensor in harsh environments.

-

Wide Operating Temperature: Suitable for extreme industrial conditions.

-

Compatibility: Designed to integrate seamlessly with Bently Nevada 3300 XL monitoring systems and other compatible instrumentation.

-

Long Cable Options: Allows installation flexibility even in challenging field environments.

-

Non-Contact Measurement: Eliminates wear and reduces maintenance needs.

-

Proven Reliability: Globally recognized in critical asset monitoring, with extensive operational history.

-

Low Noise Output: Improves signal clarity for better analysis.

-

Customization: Various tip styles, cable lengths, and connector options available.

-

Industry Standard: Widely adopted in vibration monitoring, simplifying operator training and system integration.

Frequently Asked Questions (FAQ)

-

What is the sensing range of this proximity probe?

The sensing range is 8 mm, designed to accurately measure shaft displacement within this gap. -

Can the cable length be customized?

Yes, cable lengths can be tailored to fit specific installation requirements. -

Is this probe compatible with all Bently Nevada monitoring systems?

It is primarily designed for the 3300 XL system but may be compatible with other models; verification is recommended. -

What environments can this probe operate in?

It supports a wide temperature range (-40 °C to +121 °C) and is resistant to harsh industrial conditions. -

What type of signal output does the probe provide?

It produces an AC voltage output proportional to the gap between the probe tip and the target. -

How is the probe mounted?

It can be mounted using threaded or flange options depending on the specific probe variant. -

What maintenance does the probe require?

Since it is a non-contact sensor, maintenance is minimal, mostly involving periodic inspection and cleaning of the tip. -

Is the probe suitable for explosive environments?

Certain versions are rated for hazardous locations; please check the exact model specifications. -

What is the probe tip material?

The tip is typically potted or made with materials to withstand wear and environmental exposure. -

Can the probe detect shaft rubs or contact?

While designed for non-contact measurement, abnormal vibration patterns detected may indicate rub conditions.

Recommended Related Models (Same Series or Closely Related)

| Model Number | Sensing Range | Tip Size | Cable Length | Connector Type |

|---|---|---|---|---|

| 330103-00-06-40-02-00 | 8 mm | 8 mm | Custom | MIL-C-26482 |

| 330104-00-06-50-02-00 | 12 mm | 12 mm | Custom | MIL-C-26482 |

| 330105-00-06-50-02-00 | 8 mm | 8 mm | Custom | Integral Connector |

| 330106-00-06-50-02-00 | 5 mm | 5 mm | Custom | MIL-C-26482 |

| 330107-00-06-50-02-00 | 10 mm | 10 mm | Custom | Threaded Connector |

| 330108-00-06-50-02-00 | 8 mm | 8 mm | Custom | Flange Mount |

Popular Models from Bently Nevada Brand

| Model Number | Description | Application | Key Feature |

|---|---|---|---|

| 330103-00-06-50-02-00 | 8mm Proximity Probe (3300 XL) | Vibration monitoring | Rugged design, wide temp |

| 330330-00-00-00-00-00 | 3300 XL Sensor Module | Shaft displacement | Modular, high accuracy |

| 330104-00-06-50-02-00 | 12mm Proximity Probe | Large shaft displacement | Extended sensing range |

| 330150-00-06-00-00-00 | 3300 XL Monitor | System monitor | Real-time diagnostics |

| 3500/05/00-00-00-00-00 | 3500 Series Monitor | High-end vibration system | Enhanced data analytics |

| 19081-02-02-10-10-00 | 1900 Series Proximity Probe | General purpose | Compact, easy install |

Excellent PLC

Excellent PLC