| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview:

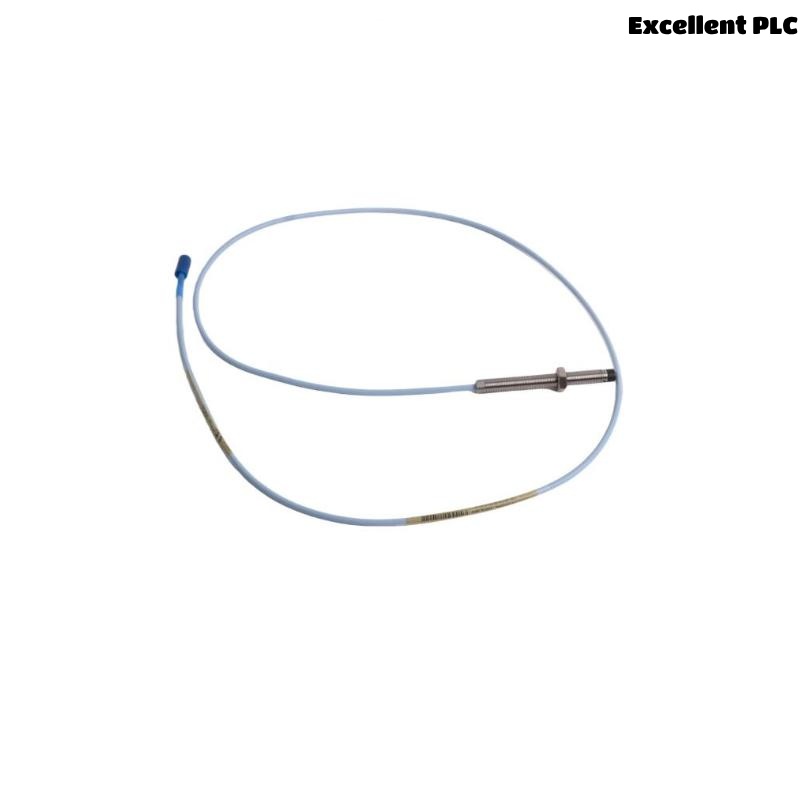

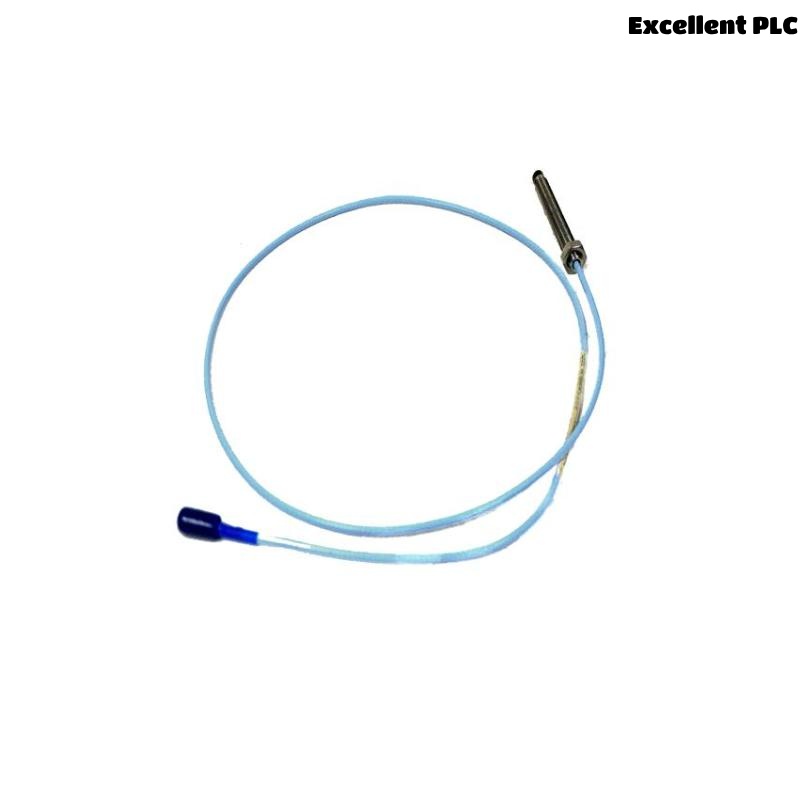

The Bently Nevada 330103-00-06-50-02-05 3300 XL 8mm Eddy Current Probe is a high-performance vibration monitoring device designed for critical machinery protection. Part of the renowned 3300 XL series, this eddy current probe is specifically designed to measure the displacement and vibration of machinery shafts, providing accurate, real-time data for predictive maintenance and fault detection.

The probe uses the eddy current principle to detect changes in the relative position of a target object. This is particularly valuable in environments where conventional methods of measurement may not be applicable due to space constraints, high temperatures, or electrical interference. The 8mm diameter of the probe allows it to be used in a wide range of applications, making it versatile enough to monitor various types of rotating machinery in industries such as power generation, oil & gas, chemical processing, and manufacturing.

The 3300 XL Eddy Current Probe is designed to be highly durable, with an extended operating life and robust performance even under harsh conditions. It ensures continuous monitoring of machinery health, providing early warnings of potential issues before they lead to costly failures or downtime.

Product Specifications:

| Specification | Details |

|---|---|

| Model | Bently Nevada 330103-00-06-50-02-05 |

| Total Length | 5.0 meters |

| Weight | 1.615 kg |

| Probe Diameter | 8 mm |

| Measurement Type | Eddy Current |

| Cable Length | 5.0 meters |

| Operating Temperature | -40°C to +85°C |

| Signal Output | Analog (4-20 mA or 0-10V) |

| Mounting Type | Direct Surface Mounting |

| Protection Rating | IP65 |

| Compliance | CE, UL Certified |

Applications:

The Bently Nevada 330103-00-06-50-02-05 3300 XL 8mm Eddy Current Probe is used in numerous industrial applications where accurate vibration and displacement monitoring are essential for the safe operation of machinery:

-

Power Generation: In power plants, the probe monitors the health of critical turbines, compressors, and other rotating machinery, ensuring smooth and efficient operation.

-

Oil & Gas: In oil rigs and refineries, the probe is used for monitoring pumps, motors, and compressors, providing vital data that prevents unplanned shutdowns and expensive repairs.

-

Chemical Processing: Used to monitor the performance of pumps, reactors, and turbines, this probe ensures optimal operation of machinery in the chemical production process.

-

Manufacturing & Heavy Industry: The probe is an ideal solution for monitoring the performance of motors, generators, and other machinery in steel mills, automotive manufacturing, and mining operations.

-

HVAC Systems: Used in HVAC systems, this probe ensures the health of cooling towers, air handlers, and blowers by continuously monitoring their vibrations and displacement.

-

Marine & Aerospace: In marine and aerospace applications, the eddy current probe is crucial for maintaining the performance of engines and turbines, minimizing downtime and preventing failure.

-

Automated Manufacturing Lines: The 3300 XL probe helps ensure the reliability and efficiency of high-speed automated production lines by monitoring machinery vibration levels in real time.

Product Advantages:

-

Highly Accurate Vibration Monitoring: The eddy current principle used by the probe provides precise vibration and displacement data, essential for detecting early signs of machine wear or failure.

-

Versatile Design: The 8mm diameter makes it suitable for a wide variety of machines, providing flexibility across different types of machinery.

-

Long Cable Length: The 5-meter cable length allows the probe to be easily positioned in hard-to-reach areas, making it perfect for large machines or tight spaces.

-

Real-time Monitoring: The Bently Nevada 3300 XL probe ensures continuous, real-time monitoring of critical machinery health, reducing downtime and preventing unexpected failures.

-

Durable and Reliable: With a rugged design, the probe operates reliably in harsh environments, with an IP65 protection rating ensuring it remains safe from dust and water.

-

Wide Temperature Range: It can function in extreme temperatures ranging from -40°C to +85°C, making it suitable for a wide range of industrial environments.

-

Easy Integration: The probe’s analog signal output (4-20 mA or 0-10V) allows for simple integration with existing control systems for monitoring and diagnostics.

-

Low Maintenance: Designed for extended use, the probe requires minimal maintenance, which contributes to reducing overall operational costs.

-

Prevents Unplanned Shutdowns: By providing early warning signals of potential issues such as shaft misalignment, bearing wear, or imbalance, the probe minimizes the risk of costly unplanned downtime.

-

Industry Proven: Trusted in critical industrial applications for over 30 years, the 3300 XL Eddy Current Probe is a well-established solution for reliable vibration monitoring.

FAQs:

-

What is the total length of the Bently Nevada 3300 XL Eddy Current Probe?

The total length of the probe is 5.0 meters. -

What is the weight of the probe?

The probe weighs 1.615 kg. -

What is the diameter of the probe?

The probe has an 8 mm diameter. -

What measurement principle does the probe use?

The probe uses the eddy current principle to measure displacement and vibration. -

What is the temperature range for operation?

The probe operates in temperatures ranging from -40°C to +85°C. -

What is the signal output from the probe?

The probe has an analog output, typically 4-20 mA or 0-10V. -

What is the protection rating of the probe?

The probe has an IP65 protection rating, making it resistant to dust and water ingress. -

What types of machinery can the probe monitor?

The probe is designed to monitor a wide variety of rotating machinery, including turbines, compressors, pumps, and motors. -

What industries benefit from using the 3300 XL Eddy Current Probe?

The probe is used in industries such as power generation, oil & gas, chemical processing, manufacturing, and HVAC systems. -

How does the 3300 XL Eddy Current Probe help prevent unplanned shutdowns?

By continuously monitoring machine vibrations and displacement, the probe provides early detection of potential issues, allowing for proactive maintenance and minimizing downtime.

Recommended Products:

| Model | Description |

|---|---|

| 330103-00-06-30-02-05 | 3300 XL 8 mm Eddy Current Probe with 3.0-meter cable length |

| 330103-00-06-70-02-05 | 3300 XL 8 mm Eddy Current Probe with 7.0-meter cable length |

| 330103-00-06-80-02-05 | 3300 XL 8 mm Eddy Current Probe with extended mounting options |

| 330103-00-06-40-02-05 | 3300 XL 8 mm Eddy Current Probe with enhanced signal processing |

| 330103-00-06-20-02-05 | 3300 XL 8 mm Eddy Current Probe for high-temperature environments |

| 330103-00-06-90-02-05 | 3300 XL 8 mm Eddy Current Probe for multi-axis vibration measurement |

Popular Bently Nevada Models:

| Model | Description |

|---|---|

| 21000-28-05-00-028-03-02 | Industrial cable for high-performance data and power transmission. |

| 21000-28-05-15-012-04-02 | 12-meter cable designed for reliable signal and power distribution. |

| 21000-28-05-15-028-04-02 | 28-meter cable optimized for industrial control systems. |

| 21000-34-05-00-030-03-02 | 30-meter heavy-duty cable designed for large-scale systems. |

| 21000-28-05-15-020-04-02 | 20-meter cable version for extended reach and enhanced durability. |

| 21000-28-05-10-012-02-02 | 12-meter cable offering high insulation and extended durability for automation systems. |

Excellent PLC

Excellent PLC