| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

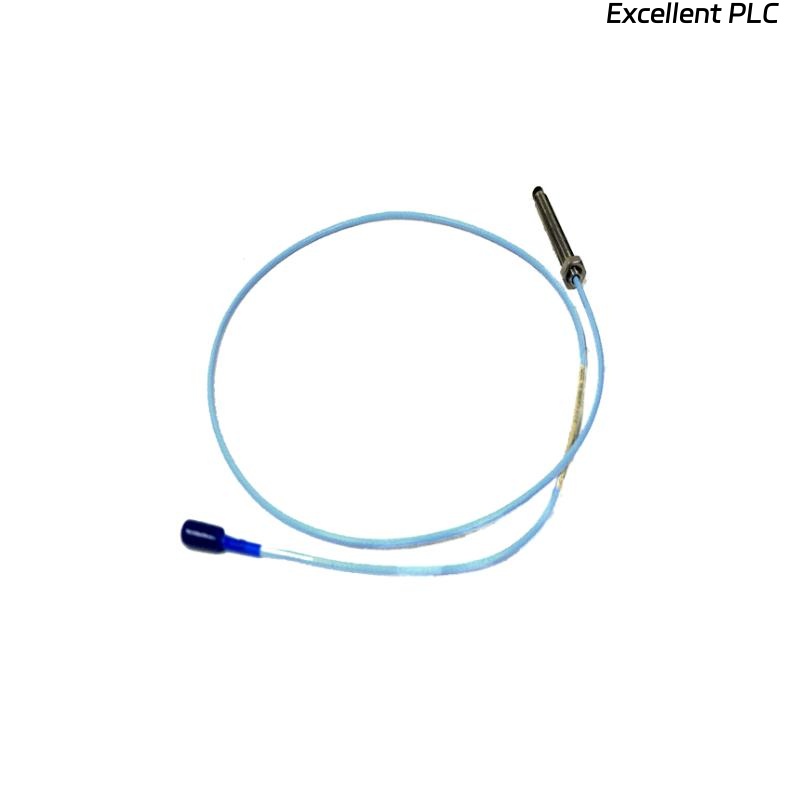

The Bently Nevada 330103-00-06-50-02-RU is an 8 mm proximity probe from the 3300 XL series, designed for accurate, non-contact measurement of shaft vibration and displacement in rotating machinery. With a 5.0-meter cable, this probe is ideal for installations requiring extended reach without compromising signal integrity. The probe tip is made of PPS (Polyphenylene Sulfide), while the housing is stainless steel, providing reliable operation in harsh industrial environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330103-00-06-50-02-RU |

| Measurement Range | 8 mm |

| Total Length | 5.0 meters |

| Weight | 1.615 kg |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Housing Material | Stainless Steel (AISI 303/304) |

| Connector Type | Miniature Coaxial ClickLoc™ |

| Cable Type | Standard Industrial Cable |

| Thread Type | M10 × 1 |

| Operating Temperature | –40 °C to +120 °C |

| Target Material | AISI 4140 Steel |

| Compliance | API 670 4th Edition |

Applications

-

Vibration Monitoring: Detect radial and axial shaft vibrations for predictive maintenance.

-

Shaft Displacement Measurement: Provides accurate data for alignment and balance optimization.

-

Keyphasor® Pulse Output: Supplies synchronization signals for machinery protection and control systems.

-

Harsh Environment Operation: Performs reliably in high temperature, humid, or dusty conditions.

Product Advantages

-

High Accuracy: Non-contact measurement with excellent repeatability.

-

Robust Construction: PPS tip and stainless steel housing withstand harsh environments.

-

Compatibility: Fully integrates with 3300 XL monitoring systems.

-

Standards Compliance: Meets API 670 machinery protection requirements.

-

Flexible Installation: 5-meter cable allows versatile positioning.

FAQ

Q1: How should the probe-to-shaft clearance be set?

A1: Use a feeler gauge to ensure the gap matches the recommended specification.

Q2: Can the probe operate across varying rotational speeds?

A2: Yes, it maintains measurement accuracy throughout the rated speed range.

Q3: How can electrical interference be minimized?

A3: Route cables away from electrical noise sources, maintain proper shielding, and secure all connections.

Q4: How is probe functionality verified after installation?

A4: Perform a system self-test and check Keyphasor® pulse and vibration signals.

Q5: Is the PPS tip compatible with all target materials?

A5: Yes, it is compatible with standard target alloys.

Q6: How is the Keyphasor® signal timing confirmed?

A6: Compare the output to a reference pulse under stable operating conditions.

Q7: Can the cable length be extended beyond 5 meters?

A7: Signal degradation may occur; please contact us for guidance.

Q8: What indicates a potential probe malfunction?

A8: Irregular pulses, dropouts, or noise spikes suggest issues with the probe or cable.

Q9: Is recalibration required when replacing the probe?

A9: No, 3300 XL probes are plug-and-play.

Q10: How can signal problems be troubleshooted?

A10: Check the probe gap, cable integrity, and grounding; for expert assistance, please contact us.

Recommended Models (Same Series / Related)

| Model | Description |

|---|---|

| 330101-00-06-10-02-R0 | 8 mm probe, 1 m standard cable |

| 330102-00-06-10-02-R0 | 8 mm armored probe, 1 m cable |

| 330103-00-06-10-02-R0 | Standard 8 mm probe, 1 m cable |

| 330104-00-06-10-02-R0 | Smooth-case 8 mm probe, 1 m cable |

| 330191-00-06-10-02-R0 | Low-temperature 8 mm probe, 1 m cable |

| 330106-00-06-10-02-R0 | Reverse-mount 8 mm probe, 1 m armored cable |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330103-00-03-10-02-RU | Standard module for reliable industrial automation |

| 330103-00-03-50-02-CN | High-capacity module for enhanced data processing |

| 330103-00-03-50-11-00 | Compact module optimized for low-power operations |

| 330103-00-03-10-01-EU | Redundant module for mission-critical system applications |

| 330103-00-03-50-01-US | Multi-protocol module for flexible system integration |

| 330103-00-03-50-12-JP | High-speed module for real-time monitoring and control |

Excellent PLC

Excellent PLC