| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview:

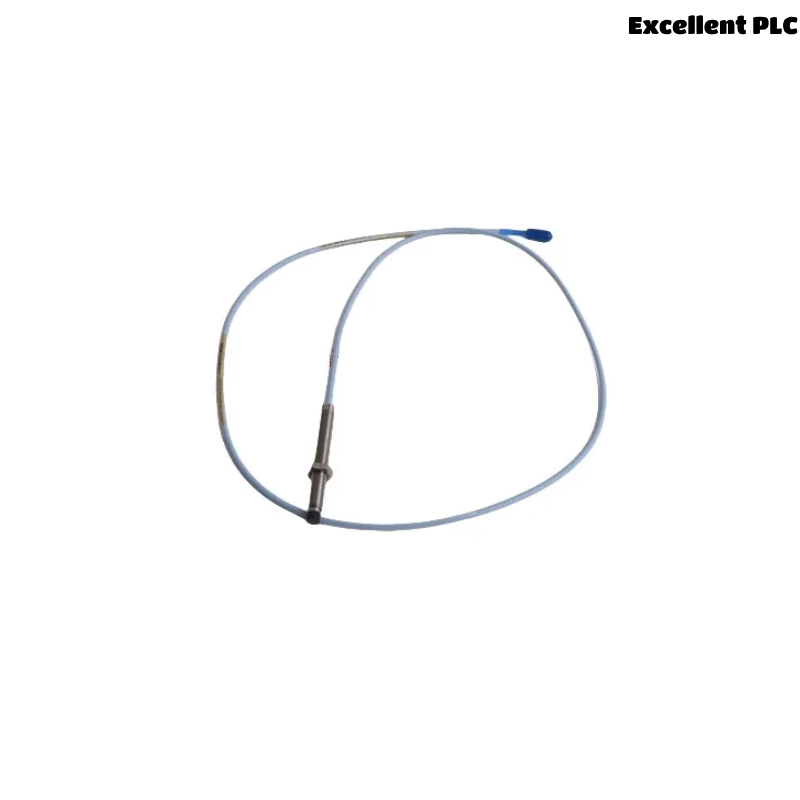

The Bently Nevada 330103-00-06-90-02-00 3300 XL 8mm Eddy Current Probe is designed for precision vibration and displacement measurement in rotating machinery, offering a robust solution for machinery protection and condition monitoring. Part of the 3300 XL series, this eddy current probe is engineered for high-performance, continuous monitoring of critical equipment, helping to prevent unplanned shutdowns and costly repairs in industries where reliability is paramount.

Utilizing the eddy current principle, the probe detects the displacement and vibration of machinery shafts, providing real-time data on the health of turbines, compressors, motors, and other rotating equipment. Its 8mm diameter design ensures compatibility with a wide range of machinery, and its 9.0-meter cable length provides flexibility in installation for both compact and expansive setups. With its high accuracy and durable construction, this probe ensures optimal performance even in harsh industrial environments.

The 3300 XL 8mm Eddy Current Probe is trusted by industries like power generation, oil and gas, chemical processing, and manufacturing for its ability to reliably monitor machinery and detect potential issues before they lead to catastrophic failures or downtime.

Product Specifications:

| Specification | Details |

|---|---|

| Model | Bently Nevada 330103-00-06-90-02-00 |

| Total Length | 9.0 meters |

| Weight | 2.907 kg |

| Probe Diameter | 8 mm |

| Measurement Type | Eddy Current |

| Cable Length | 9.0 meters |

| Operating Temperature | -40°C to +85°C |

| Signal Output | Analog (4-20 mA or 0-10V) |

| Mounting Type | Direct Surface Mounting |

| Protection Rating | IP65 |

| Compliance | CE, UL Certified |

Applications:

The Bently Nevada 330103-00-06-90-02-00 3300 XL 8mm Eddy Current Probe is an essential tool in industries where machinery health and performance are critical. Its applications include:

-

Power Generation: In power plants, the probe monitors turbines, generators, and other critical machinery to detect any vibration or displacement issues that could lead to equipment failure.

-

Oil & Gas: Used on oil rigs and in refineries, it helps protect essential equipment like compressors, pumps, and motors, reducing the risk of costly downtime.

-

Chemical Processing: The probe ensures the smooth operation of pumps, reactors, and turbines in chemical plants, providing reliable data to prevent potential failures.

-

Manufacturing & Heavy Industry: It is ideal for manufacturing environments where rotating machinery such as motors, conveyors, and mills are in constant use, offering protection and improving operational efficiency.

-

HVAC Systems: The eddy current probe is used in HVAC systems, ensuring that blowers, fans, and cooling towers are operating within acceptable vibration thresholds.

-

Marine & Aerospace: The probe plays a critical role in marine and aerospace industries, where it ensures the reliability of turbine engines and other high-precision rotating machinery.

-

Mining Operations: In mining, the probe monitors the health of crushers, pumps, and other heavy equipment used in harsh environments.

Product Advantages:

-

High Precision Monitoring: The eddy current principle ensures precise measurement of machinery vibration and displacement, which is essential for early fault detection.

-

Long Cable Length: With a 9.0-meter cable, the probe offers flexibility for installation in large machines or installations that require long cable runs.

-

Durable and Reliable: The probe is designed to withstand harsh environmental conditions, with an IP65 protection rating that ensures it remains operational in dusty and wet conditions.

-

Real-time Monitoring: It provides real-time feedback on machine health, allowing operators to take immediate action and reduce the risk of failure.

-

Wide Temperature Range: The 3300 XL probe can operate in temperatures from -40°C to +85°C, making it suitable for a wide range of industrial settings.

-

Versatility in Machinery: The 8mm diameter makes the probe compatible with a wide variety of rotating machinery, including turbines, compressors, and motors.

-

Low Maintenance Requirements: Designed for long-term reliability, this probe requires minimal maintenance, leading to cost savings over time.

-

Prevents Downtime: By continuously monitoring key parameters, the probe helps prevent unexpected failures, reducing unplanned downtime and improving overall productivity.

-

Easy Integration: The analog output (4-20 mA or 0-10V) makes it easy to integrate into existing machinery protection and monitoring systems.

-

Industry-Proven Technology: The 3300 XL series has been widely adopted for over three decades, providing a trusted solution for vibration and displacement monitoring.

FAQs:

-

What is the total length of the Bently Nevada 3300 XL Eddy Current Probe?

The total length of the probe is 9.0 meters. -

What is the weight of the probe?

The probe weighs 2.907 kg. -

What is the diameter of the probe?

The probe has an 8 mm diameter. -

What measurement principle does the probe use?

The probe utilizes the eddy current principle to measure vibration and displacement. -

What is the operating temperature range for the 3300 XL probe?

The probe operates within a temperature range of -40°C to +85°C. -

What output does the probe provide?

The probe provides an analog signal output (4-20 mA or 0-10V). -

What industries use the Bently Nevada 3300 XL Eddy Current Probe?

The probe is widely used in industries such as power generation, oil & gas, chemical processing, manufacturing, and HVAC. -

How does the probe help prevent machinery failure?

By monitoring vibration and displacement in real time, the probe detects issues early, allowing for preventative maintenance and reducing the risk of costly breakdowns. -

Is the 3300 XL probe easy to install?

Yes, the probe is designed for direct surface mounting and is easy to install on a wide range of machinery. -

What protection rating does the probe have?

The probe has an IP65 protection rating, making it suitable for use in harsh industrial environments.

Recommended Products:

| Model | Description |

|---|---|

| 330103-00-06-70-02-00 | 3300 XL 8 mm Eddy Current Probe with 7.0-meter cable length |

| 330103-00-06-80-02-00 | 3300 XL 8 mm Eddy Current Probe with 8.0-meter cable length |

| 330103-00-06-50-02-00 | 3300 XL 8 mm Eddy Current Probe with 5.0-meter cable length |

| 330103-00-06-30-02-00 | 3300 XL 8 mm Eddy Current Probe with 3.0-meter cable length |

| 330103-00-06-90-02-01 | 3300 XL 8 mm Eddy Current Probe with extended temperature range |

| 330103-00-06-60-02-00 | 3300 XL 8 mm Eddy Current Probe for specialized monitoring systems |

Popular Bently Nevada Models:

| Model | Description |

|---|---|

| 330103-00-06-50-02-05 | 3300 XL 8 mm Eddy Current Probe with 5-meter cable length |

| 330103-00-06-40-02-00 | 3300 XL 8 mm Eddy Current Probe with 4-meter cable length |

| 330103-00-06-30-02-05 | 3300 XL 8 mm Eddy Current Probe with 3-meter cable length |

| 330103-00-06-10-02-00 | 3300 XL 8 mm Eddy Current Probe for small machinery |

| 330103-00-06-60-02-05 | 3300 XL 8 mm Eddy Current Probe for advanced vibration monitoring |

| 330103-00-06-20-02-00 | 3300 XL 8 mm Eddy Current Probe for sensitive equipment monitoring |

Excellent PLC

Excellent PLC