| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

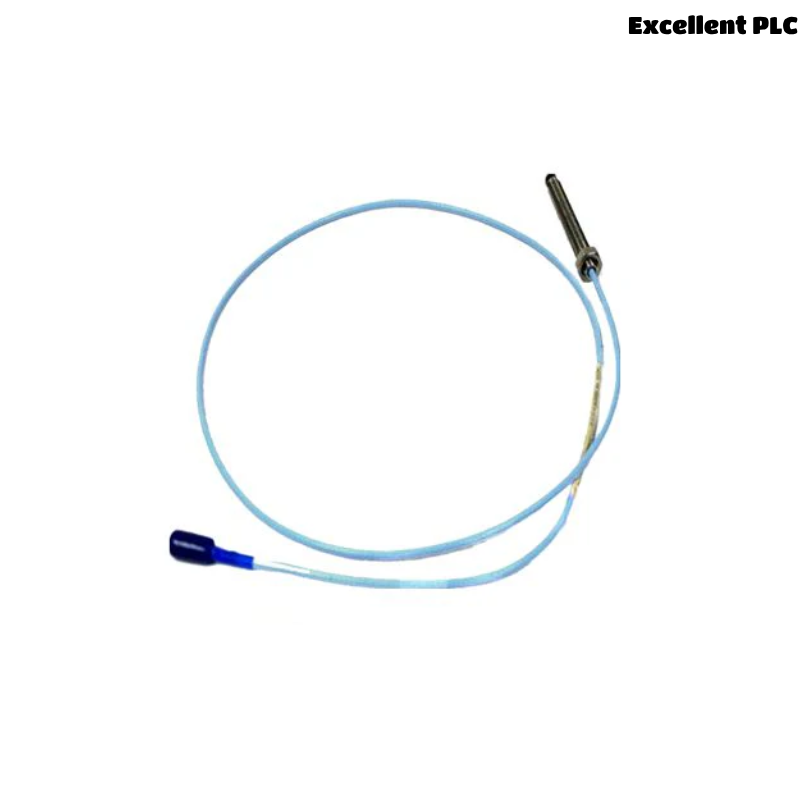

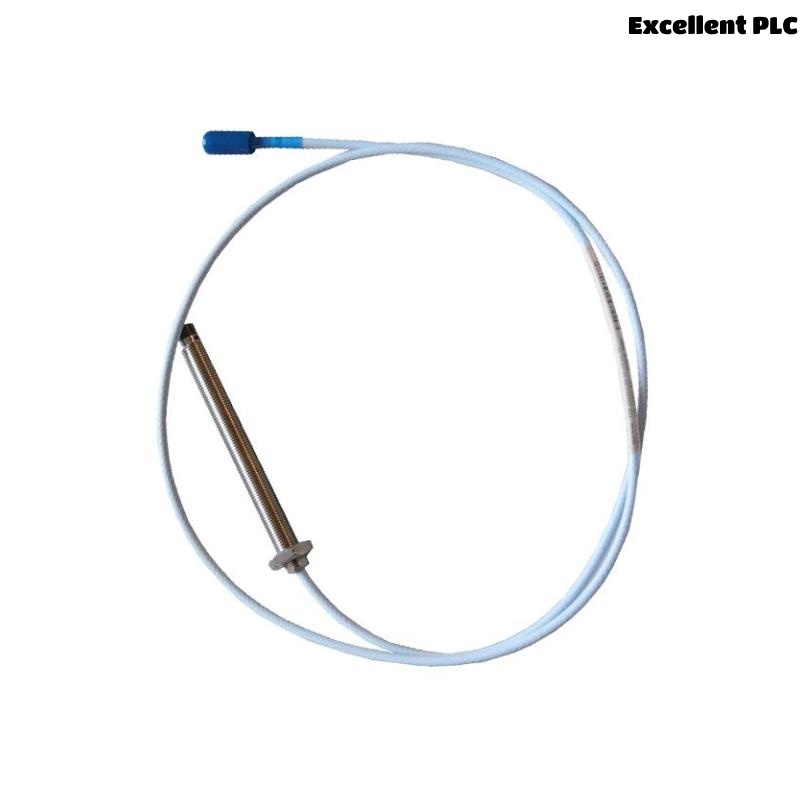

The Bently Nevada 330103-00-07-05-02-00 is a part of the 3300 XL series and is an 8 mm proximity probe designed for high-performance vibration monitoring and shaft alignment in rotating machinery. The probe is engineered to provide precise measurement of shaft vibrations, helping to detect potential machinery malfunctions before they result in failure. Its robust construction allows it to perform effectively in harsh industrial environments.

This proximity probe is integral to predictive maintenance programs, offering real-time data for ensuring machinery operates efficiently and reliably, reducing downtime and maintenance costs. The 3300 XL probe has been designed for ease of integration into various condition monitoring systems, making it a popular choice for industries relying on vibration and alignment monitoring.

Product Parameters

| Parameter | Value |

|---|---|

| Model Number | 330103-00-07-05-02-00 |

| Probe Type | 3300 XL 8 mm |

| Measurement Type | Proximity |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Diameter | 8 mm |

| Shaft Size | Suitable for shaft diameters up to 150 mm |

| Output Type | DC Voltage |

| Cable Length | 0.5 meter |

| Operating Temperature | -40°C to +120°C |

| Mounting Type | Integral Mounting |

| Sensitivity | High Sensitivity |

| Protection Class | IP67 |

Applications

The Bently Nevada 330103-00-07-05-02-00 proximity probe is primarily used in applications where the accurate monitoring of vibrations and shaft movement is critical. The common applications for this probe include:

-

Rotating Equipment Monitoring: Used in turbines, motors, compressors, and other rotating equipment to measure vibration and shaft displacement.

-

Condition-Based Maintenance: The probe plays a vital role in condition-based maintenance programs by providing valuable data to predict potential failures before they occur.

-

Alignment Monitoring: Ensures the precise alignment of rotating machinery, preventing costly damage caused by misalignment.

-

Industrial Automation: The probe can be integrated into automated systems for continuous monitoring of equipment health in various industrial environments.

-

Power Generation and Petrochemical Industries: Ideal for high-reliability industries, such as power plants and oil refineries, where uptime is crucial.

Product Advantages

-

High Accuracy: The 3300 XL series probes provide highly accurate measurements of vibration and shaft displacement, ensuring reliable data for maintenance teams.

-

Durable Construction: Designed to withstand harsh environmental conditions, the probe is built for longevity, even in demanding industrial settings.

-

Easy Installation: The probe’s integral mounting system simplifies installation and reduces setup time, minimizing downtime during equipment maintenance.

-

Long Operational Life: The high-quality materials and construction provide a long service life, making the probe a cost-effective investment for long-term monitoring.

-

Real-Time Monitoring: Delivers real-time data that allows for proactive decision-making, enabling better control over maintenance schedules and minimizing operational disruptions.

Frequently Asked Questions (FAQs)

-

What is the operating temperature range of the 3300 XL 8 mm proximity probe?

-

The probe operates in a temperature range of -40°C to +120°C, making it suitable for a wide range of industrial environments.

-

-

How is the 3300 XL probe mounted?

-

The probe features an integral mounting system, which allows for quick and easy installation onto rotating machinery.

-

-

What is the maximum shaft size this probe can be used with?

-

The 3300 XL 8 mm probe is designed for use with shafts up to 150 mm in diameter.

-

-

Is the 3300 XL 8 mm probe suitable for hazardous environments?

-

Yes, the probe is engineered to operate reliably in harsh and hazardous industrial environments, providing a high degree of durability.

-

-

What types of machinery benefit from using this probe?

-

The probe is ideal for monitoring rotating equipment such as turbines, compressors, motors, and other machinery where vibration and alignment monitoring is crucial.

-

-

How does the 3300 XL probe contribute to predictive maintenance?

-

By providing precise real-time data on shaft movement and vibration, the probe helps to detect potential problems early, enabling proactive maintenance and preventing costly downtime.

-

-

What is the output type of the 3300 XL proximity probe?

-

The probe provides a DC voltage output, which is ideal for integration with vibration monitoring and control systems.

-

-

What is the sensitivity level of the 3300 XL 8 mm probe?

-

The probe has a high sensitivity level, enabling it to detect minute changes in shaft movement and vibration, offering early warning signs of machinery malfunctions.

-

-

How do I maintain the 3300 XL probe?

-

The 3300 XL is low-maintenance but periodic calibration and visual checks are recommended to ensure optimal performance.

-

-

Can the 3300 XL 8 mm probe be used with Bently Nevada’s other vibration monitoring systems?

-

Yes, it is fully compatible with other Bently Nevada vibration monitoring systems, allowing for seamless integration into your machinery monitoring setup.

Related Models

| Model | Description |

|---|---|

| 330103-00-07-05-02-01 | 3300 XL 8 mm proximity probe with extended cable |

| 330104-00-07-05-02-00 | 3300 XL 8 mm proximity probe (different configuration) |

| 330100-00-07-05-02-00 | 3300 XL 5 mm proximity probe |

| 330106-00-07-05-02-00 | 3300 XL 12 mm proximity probe |

| 330105-00-07-05-02-00 | 3300 XL 8 mm proximity probe with higher sensitivity |

| 330101-00-07-05-02-00 | 3300 XL 8 mm proximity probe with longer cable length |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330500-00-01-10-00-00 | 3300 XL 8 mm vibration probe |

| 330350-00-01-00-00-00 | 3300 XL vibration monitoring system |

| 330420-00-01-01-01-00 | 3300 XL vibration transducer |

| 330400-00-02-10-02-00 | 3300 XL 10 mm proximity probe |

| 330101-00-01-10-00-00 | 3300 XL system with 5 mm probe |

| 350101-00-02-10-00-01 | 3500 vibration monitoring system |

Excellent PLC

Excellent PLC