| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

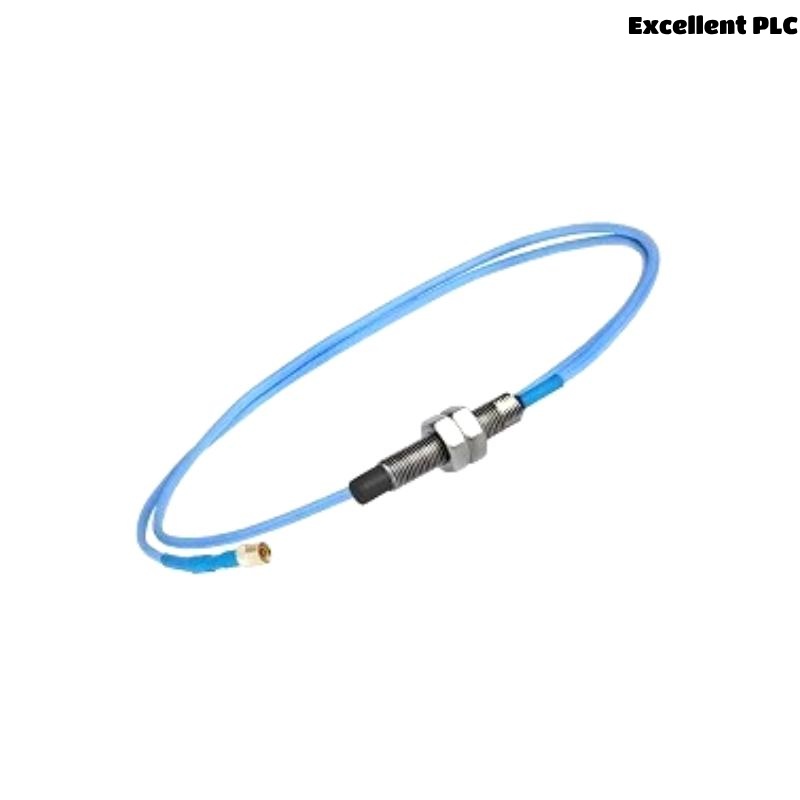

The Bently Nevada 330103-00-07-10-02-05 proximity probe is a core component of the renowned 3300 XL series, engineered to provide precise and dependable measurement of shaft displacement and vibration in rotating machinery. This 8mm probe offers a finely tuned sensing range ideal for critical machinery monitoring applications, delivering high accuracy and durability under demanding industrial conditions.

Designed to endure harsh environments, the 330103-00-07-10-02-05 features a stainless steel housing and a robust probe tip that resists wear and corrosion. It supports non-contact measurement, minimizing wear on the probe and the monitored shaft, thereby reducing maintenance frequency and costs. Its compatibility with the Bently Nevada 3300 XL monitoring system ensures seamless integration for real-time condition monitoring.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330103-00-07-10-02-05 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Sensing Range | 8 mm |

| Total Length | 1 meter |

| Weight | 0.323 kg |

| Operating Temperature | -40 °C to +121 °C (-40 °F to +250 °F) |

| Connector Type | MIL-C-26482 style military-grade connector |

| Housing Material | Stainless Steel |

| Output Signal | AC voltage proportional to target gap |

| Cable Length | Customizable based on installation needs |

| Mounting Options | Threaded or flange mounting options |

Applications

The 3300 XL 8mm proximity probe serves a broad range of industries that require continuous monitoring of rotating equipment:

-

Power Generation: Used to monitor turbines and generators for shaft movement and vibration anomalies.

-

Oil and Gas: Monitors pumps, compressors, and turbines to ensure operational reliability.

-

Aerospace: Employed in engine test stands and other rotating machinery requiring precise vibration measurements.

-

Manufacturing: Monitors motors, pumps, and gearboxes to facilitate predictive maintenance.

-

Marine: Provides shaft vibration and displacement monitoring in propulsion and auxiliary systems.

-

Mining: Used on heavy machinery such as crushers and mills to detect early wear and imbalance.

-

Chemical Processing: Ensures reliable operation of pumps and compressors in process plants.

Advantages

-

Precision Monitoring: Delivers accurate displacement measurements critical for early fault detection.

-

Durable Design: Stainless steel housing and robust tip resist corrosion and wear, even in harsh environments.

-

Wide Operating Temperature: Functions effectively between -40 °C and +121 °C.

-

Flexible Installation: Custom cable lengths and multiple mounting options accommodate various applications.

-

Non-Contact Measurement: Reduces probe and shaft wear, lowering maintenance requirements.

-

Seamless System Integration: Designed for compatibility with Bently Nevada 3300 XL monitoring systems.

-

Reliable Connectivity: Uses military-grade connectors to ensure stable, noise-free signal transmission.

-

Proven Industrial Reliability: Widely trusted in critical asset monitoring worldwide.

-

Low Maintenance Needs: Requires only occasional cleaning of the probe tip.

-

Suitable for Hazardous Environments: Specific versions certified for use in explosive atmospheres.

Frequently Asked Questions (FAQ)

-

What is the sensing distance of this probe?

It has an 8 mm sensing range for precise shaft displacement measurement. -

Can the cable length be customized?

Yes, cable lengths can be tailored to suit different installation requirements. -

What temperature range can the probe operate within?

The probe works reliably from -40 °C to +121 °C. -

What type of output does the probe generate?

It produces an AC voltage proportional to the gap between the probe tip and the target. -

Is this probe compatible with all Bently Nevada monitoring systems?

It is designed for the 3300 XL series but may work with other systems upon confirmation. -

What mounting options are available?

The probe can be mounted using threaded or flange options. -

How durable is the probe tip?

The probe tip is made from wear-resistant materials to withstand tough operating conditions. -

Does this probe require frequent maintenance?

Maintenance is minimal; periodic tip cleaning and inspection are usually sufficient. -

Is the probe suitable for use in hazardous areas?

Certain configurations comply with hazardous location certifications; confirm with the supplier. -

What connector type does this probe use?

The probe uses a MIL-C-26482 style military-grade connector for secure signal transmission.

Recommended Related Models (Same Series or Closely Related)

| Model Number | Sensing Range | Tip Diameter | Cable Length | Connector Type |

|---|---|---|---|---|

| 330103-00-06-50-02-00 | 8 mm | 8 mm | Custom | MIL-C-26482 |

| 330104-00-07-05-02-05 | 12 mm | 12 mm | Custom | MIL-C-26482 |

| 330105-00-06-50-02-00 | 8 mm | 8 mm | Custom | Integral Connector |

| 330106-00-07-05-02-05 | 5 mm | 5 mm | Custom | MIL-C-26482 |

| 330107-00-06-50-02-00 | 10 mm | 10 mm | Custom | Threaded Connector |

| 330108-00-07-05-02-05 | 8 mm | 8 mm | Custom | Flange Mount |

Popular Models from Bently Nevada Brand

| Model Number | Description | Application | Key Feature |

|---|---|---|---|

| 330103-00-07-10-02-05 | 8 mm Proximity Probe (3300 XL) | Vibration and displacement | Durable and precise |

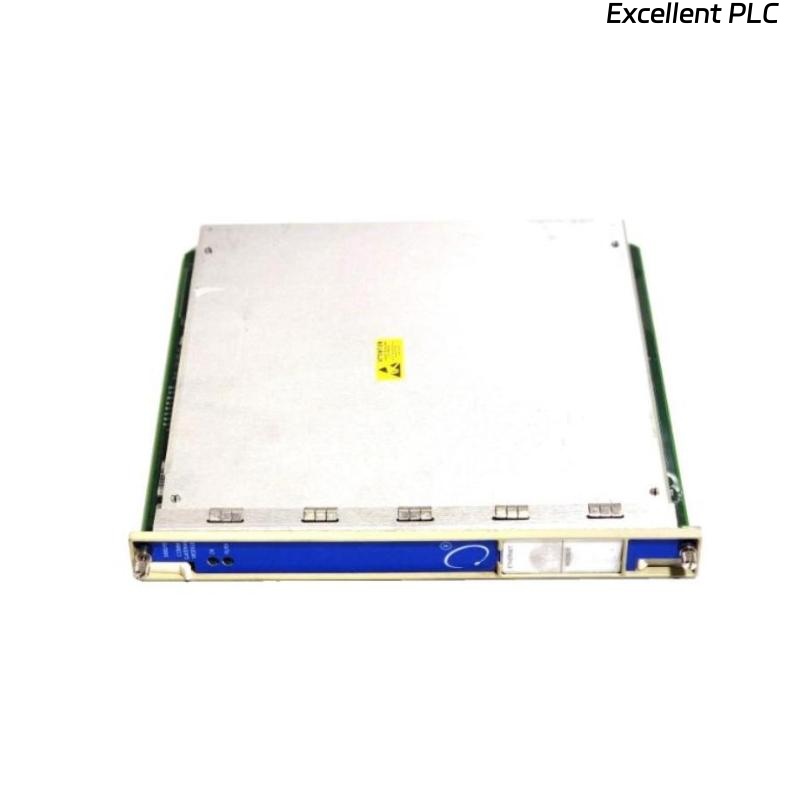

| 330330-00-00-00-00-00 | 3300 XL Sensor Module | Shaft displacement sensor | Modular and reliable |

| 330104-00-06-50-02-00 | 12 mm Proximity Probe | Large gap displacement | Extended sensing range |

| 330150-00-06-00-00-00 | 3300 XL Monitor | System condition monitor | Real-time diagnostics |

| 3500/05/00-00-00-00-00 | 3500 Series Monitor | Advanced vibration system | Enhanced analytics |

| 19081-02-02-10-10-00 | 1900 Series Proximity Probe | General purpose sensing | Compact and versatile |

Excellent PLC

Excellent PLC