| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

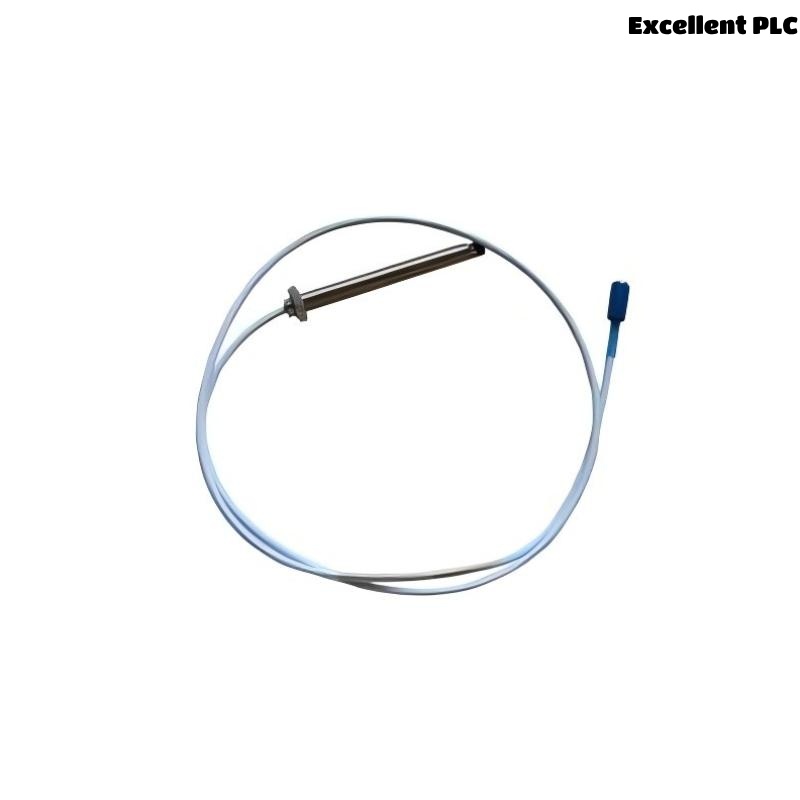

The Bently Nevada 330103-00-08-05-02-RU 3300 XL 8 mm Proximity Probe (Metric) is an advanced precision tool designed for measuring the displacement and vibration of rotating machinery components. As part of the 3300 XL series, this proximity probe offers superior measurement accuracy and sensitivity, ensuring the continuous monitoring of equipment health in industrial settings. This model, designed for metric units, is widely used in industries where critical machinery requires constant surveillance to prevent costly failures and minimize unplanned downtime.

The 3300 XL 8 mm Proximity Probe is engineered for high-performance monitoring applications and integrates seamlessly with Bently Nevada’s condition monitoring systems. It is particularly ideal for measuring shaft displacement and vibration in turbines, compressors, pumps, motors, and other rotating equipment. With its exceptional frequency range, real-time data acquisition, and precise output, this proximity probe plays a vital role in condition-based maintenance strategies.

Designed for harsh industrial environments, this proximity probe is built to withstand extreme conditions, such as high vibration, moisture, and temperature fluctuations, ensuring reliable operation even under the most challenging conditions.

Product Specifications:

| Parameter | Description |

|---|---|

| Model | 330103-00-08-05-02-RU |

| Probe Type | 8 mm Proximity Probe (Metric) |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Frequency Range | 2 Hz to 100 kHz |

| Output Type | Linear Voltage (10-30 VDC) |

| Operating Temp | -40°C to +85°C |

| Mounting | Standard Mounting (Threaded) |

| Compliance | CE, UL |

| Probe Material | Stainless Steel |

Applications:

The 3300 XL 8 mm Proximity Probe is widely used for continuous, real-time monitoring of various rotating equipment in industries that rely on high-performance machinery. Its applications extend across multiple sectors, ensuring optimal machine operation and the early detection of potential faults. Key applications include:

-

Turbine Monitoring: In power generation plants, the probe monitors turbine shaft displacement to detect issues such as misalignment, imbalance, or wear before they lead to major failures.

-

Compressor Monitoring: The probe is used in compressors to measure axial and radial displacement, helping identify mechanical problems like rotor imbalance or bearing issues that could lead to performance degradation.

-

Motor Monitoring: It helps monitor electric motors, detecting shaft misalignment, bearing wear, and other potential faults that may impact efficiency and reliability.

-

Pump Health Monitoring: In pumping systems, the probe detects shaft displacement and vibration, preventing issues such as cavitation, misalignment, or bearing failure that could damage the pump.

-

Condition Monitoring Systems: When integrated with Bently Nevada’s comprehensive condition monitoring systems, the probe provides real-time data that allows operators to take preventive action and avoid unplanned downtime.

-

High-Speed Machinery: The 3300 XL 8 mm Proximity Probe is highly effective for high-speed machinery monitoring, offering precise measurements for high-frequency vibration and displacement detection.

Industries such as power generation, oil and gas, mining, and manufacturing benefit significantly from the early detection capabilities offered by the 3300 XL 8 mm Proximity Probe.

Advantages:

-

High Measurement Sensitivity: The 3300 XL 8 mm Proximity Probe provides highly sensitive and accurate measurements of displacement and vibration, allowing early detection of even the smallest mechanical irregularities.

-

Compact Design: With a total length of 0.5 meter and a weight of only 0.161 kg, this probe is compact and easy to integrate into tight spaces, making it versatile for various applications.

-

Broad Frequency Range: Offering a frequency range of 2 Hz to 100 kHz, the probe can effectively monitor both low- and high-frequency vibrations, making it ideal for a wide range of machinery.

-

Durable Construction: Built from high-quality stainless steel, the probe is designed to withstand harsh industrial environments, ensuring durability and reliable performance in extreme conditions.

-

Real-Time Monitoring: The probe provides continuous real-time data on machinery health, allowing operators to identify and address potential issues before they result in catastrophic failure or costly downtime.

-

Low Maintenance: The 3300 XL 8 mm Proximity Probe is designed for minimal maintenance, providing long-term reliability and reducing the need for frequent service interventions.

-

Seamless Integration: It easily integrates with other Bently Nevada products, including the 3500 series of condition monitoring systems, providing a complete solution for machinery health monitoring.

-

Global Certifications: The probe complies with international standards, including CE and UL, making it suitable for deployment in various global markets.

-

Cost-Effective Solution: By offering real-time diagnostics and enabling predictive maintenance, the probe helps reduce operational costs, extending machinery lifespan and minimizing unplanned downtime.

-

Versatility in Applications: The 3300 XL 8 mm Proximity Probe is highly versatile, making it suitable for use in turbines, motors, compressors, pumps, and a wide variety of rotating machinery.

FAQ (Frequently Asked Questions)

-

What is the total length of the Bently Nevada 3300 XL 8 mm Proximity Probe?

-

The total length of the probe is 0.5 meters.

-

-

How much does the 3300 XL 8 mm Proximity Probe weigh?

-

The probe weighs 0.161 kg.

-

-

What is the frequency range of the 3300 XL 8 mm Proximity Probe?

-

The probe operates within a frequency range of 2 Hz to 100 kHz.

-

-

What type of output does the 3300 XL 8 mm Proximity Probe provide?

-

The probe provides a linear voltage output, typically in the range of 10-30 VDC.

-

-

Can the 3300 XL 8 mm Proximity Probe be used for monitoring high-speed machinery?

-

Yes, the probe is highly effective in monitoring high-speed machinery due to its broad frequency range and sensitivity.

-

-

What is the operating temperature range of the 3300 XL 8 mm Proximity Probe?

-

The probe can operate in temperatures ranging from -40°C to +85°C.

-

-

Is the 3300 XL 8 mm Proximity Probe suitable for use in turbines?

-

Yes, it is ideal for use in turbines, where it measures shaft displacement to detect issues like misalignment, imbalance, or wear.

-

-

How does the 3300 XL 8 mm Proximity Probe help with predictive maintenance?

-

By continuously monitoring vibrations and displacement, the probe helps detect early signs of potential faults, allowing for corrective action before failures occur.

-

-

What materials are used in the construction of the 3300 XL 8 mm Proximity Probe?

-

The probe is made from high-quality stainless steel, ensuring durability and resistance to harsh environments.

-

-

Can the 3300 XL 8 mm Proximity Probe be integrated with other Bently Nevada systems?

-

Yes, it can be easily integrated with Bently Nevada’s 3500 series of condition monitoring systems, providing a complete monitoring solution.

-

Recommended Models (Same Series/Related Models)

| Model | Description |

|---|---|

| 330103-00-08-05-02 | 3300 XL 8 mm Proximity Probe with extended cable for large installations. |

| 330103-00-08-05-03 | 3300 XL 8 mm Proximity Probe with enhanced temperature resistance. |

| 330103-00-08-05-04 | 3300 XL 8 mm Proximity Probe for use in high-vibration environments. |

| 330103-00-08-05-05 | 3300 XL 8 mm Proximity Probe with integrated diagnostics for real-time data analysis. |

| 330103-00-08-05-06 | 3300 XL 8 mm Proximity Probe designed for smaller machines with limited space. |

| 330103-00-08-05-07 | 3300 XL 8 mm Proximity Probe with increased accuracy for high-precision applications. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330103-06-10-50-02-00 | Standard industrial control unit with moderate I/O capabilities for general automation. |

| 330103-06-12-05-02-05 | Enhanced version with advanced diagnostics and real-time performance monitoring. |

| 330103-06-12-10-02-00 | High-performance control module with extended communication options for larger systems. |

| 330103-06-15-20-03-05 | Compact and efficient model for small-scale applications with reduced space requirements. |

| 330104-06-12-10-02-10 | Rugged design, ideal for industrial environments requiring high durability and extended temperature range. |

| 330103-06-18-25-05-00 | Advanced model with integrated network capabilities for remote monitoring and data exchange. |

Excellent PLC

Excellent PLC