| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

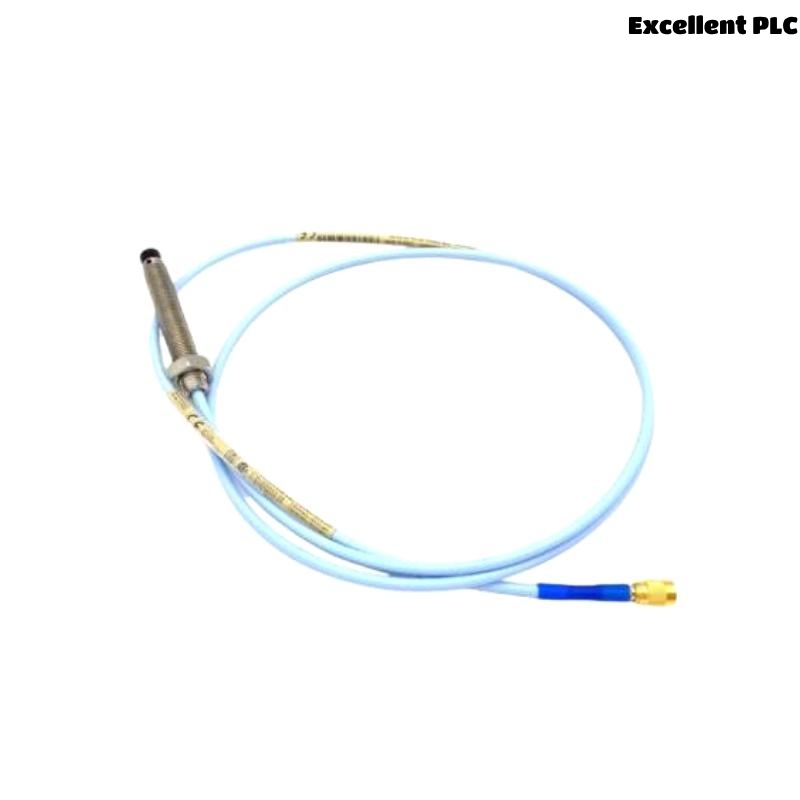

The Bently Nevada 330103-00-08-10-02-00 is an industrial-grade 8mm proximity probe engineered as part of the renowned 3300 XL series. This probe is designed to provide precise, non-contact measurement of shaft position and vibration in critical rotating equipment. The probe’s 8mm sensing tip is optimized for durability and stable signal output, making it suitable for harsh operating environments encountered in power generation, oil and gas, petrochemical, and heavy industrial sectors.

Equipped with a 10-foot cable and standard 3/8-24 UNF threaded mounting, this model ensures flexibility during installation and integration with the Bently Nevada 3300 XL vibration monitoring system. Its rugged design and reliable performance make it a trusted sensor for continuous machine health monitoring, early fault detection, and predictive maintenance programs.

Product Specifications

| Parameter | Specification |

|---|---|

| Part Number | 330103-00-08-10-02-00 |

| Product Name | Bently Nevada 3300 XL 8mm Proximity Probe |

| Tip Diameter | 8 mm |

| Thread Size | 3/8-24 UNF |

| Connector Type | Miniature coaxial connector |

| Linear Range | 0.5 mm (50 mils) |

| Output Signal | Analog voltage proportional to target distance |

| Frequency Response | DC to 10 kHz |

| Operating Temperature Range | -35°C to +177°C (-31°F to +350°F) |

| Weight | 0.323 kg |

| Total Length | Probe tip plus 10 ft cable (~2 inches probe tip length) |

| Mounting | Threaded insertion (3/8-24 UNF) |

| Compliance | API 670 compliant, RoHS |

Applications

The Bently Nevada 330103-00-08-10-02-00 proximity probe is widely utilized in:

-

Vibration and Position Monitoring on steam turbines, gas turbines, compressors, and generators.

-

Shaft Displacement Measurement for axial and radial positioning to detect misalignment or imbalance.

-

Rotating Machinery Protection systems in power plants and petrochemical facilities.

-

Hydroelectric and Wind Turbine Monitoring to track rotor behavior and mechanical integrity.

-

Pumps, Fans, and Motors where precise vibration data is crucial for maintenance decisions.

-

Condition Monitoring Programs aligned with API 670 standards.

-

Industrial Plants requiring robust, long-term machine health data acquisition.

-

Harsh Environmental Conditions such as high temperatures and mechanical vibration.

-

Integration with Bently Nevada 3300 XL Series Systems for comprehensive machinery diagnostics.

Product Advantages

-

High Accuracy and Stability: The probe delivers consistent measurements with minimal signal drift.

-

Rugged Construction: Designed to endure extreme temperatures, mechanical shock, and electrical noise.

-

Long Cable Length: The 1 meter cable provides installation flexibility in complex machinery layouts.

-

Standardized Mounting: The 3/8-24 UNF thread is widely compatible with existing machinery.

-

API 670 Compliance: Meets stringent industry standards for machinery protection.

-

Ease of Integration: Plug-and-play compatibility with the Bently Nevada 3300 XL system.

-

Superior Signal Quality: High signal-to-noise ratio ensures reliable vibration data.

-

Maintenance Friendly: Requires minimal upkeep, reducing operational costs.

-

Global Support Network: Backed by GE’s extensive service and support.

-

Non-Contact Measurement: Eliminates wear and tear, enhancing probe lifespan.

Frequently Asked Questions (FAQ)

-

What distinguishes the 330103-00-08-10-02-00 from other 3300 XL probes?

The 1 meter total length offers extended reach, suitable for larger machinery or remote sensor locations. -

What is the operating temperature range for this probe?

It functions reliably between -35°C and +177°C (-31°F to +350°F). -

How does the probe measure shaft vibration?

It senses changes in the gap between the probe tip and the rotating shaft using eddy current principles, converting displacement to voltage. -

Is this probe compatible with the original Bently Nevada 3300 system?

This model is optimized for the 3300 XL system; compatibility with older models depends on connectors and system configuration. -

What maintenance is required for this probe?

Minimal maintenance is needed; routine inspections and periodic system calibration are recommended. -

Can this probe be used in hazardous locations?

Use requires certified enclosures and adherence to safety standards applicable to the environment. -

What connector type does this probe use?

A miniature coaxial connector ensures a stable and noise-resistant connection. -

Is the cable length customizable?

Standard total length is 1 meter other cable lengths may be available on special request. -

What is the weight of the probe with cable?

0.323 kg, depending slightly on cable length. -

Can the probe detect shaft axial displacement?

Yes, it measures shaft position changes in both axial and radial directions.

Related Models in the Same Series

| Model Number | Description | Cable Length | Tip Diameter | Application |

|---|---|---|---|---|

| 330103-00-08-05-02-00 | 3300 XL 8mm Proximity Probe, 5 ft cable | 5 ft (1.52 m) | 8 mm | Standard reach monitoring |

| 330101-00-08-10-02-00 | 3300 XL 8mm Probe with 10 ft cable | 10 ft (3.05 m) | 8 mm | Extended reach for large assets |

| 330104-00-05-10-02-00 | 3300 XL 5mm Proximity Probe, 10 ft cable | 10 ft (3.05 m) | 5 mm | Compact sensing applications |

| 330105-00-08-15-02-00 | 3300 XL 8mm Probe, 15 ft cable | 15 ft (4.57 m) | 8 mm | Long cable for complex layouts |

| 330130-040-00 | 3300 XL Extension Cable | 4 m | N/A | Cable extension option |

| 330106-00-08-10-02-00 | 3300 XL 8mm Probe with special shielding | 10 ft (3.05 m) | 8 mm | Enhanced EMI protection |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Product Type | Application Area | Notes |

|---|---|---|---|

| 3500/22M | Transient Data Interface | 3500 Series Monitoring | Ethernet-enabled communication module |

| 3500/42M | Vibration Monitor Module | Turbomachinery | 4-channel vibration monitoring |

| 3500/15 | Power Supply Module | 3500 System | Redundant power supply |

| 3701/40 | Machinery Protection System | Critical rotating assets | Modular, distributed architecture |

| 330104-00-20-10-02-00 | 5mm Proximity Probe | Compact machinery monitoring | Small tip for tight clearances |

| 3500/25 | Keyphasor Module | Shaft speed and phase detection | Supports multiple inputs |

Excellent PLC

Excellent PLC