| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

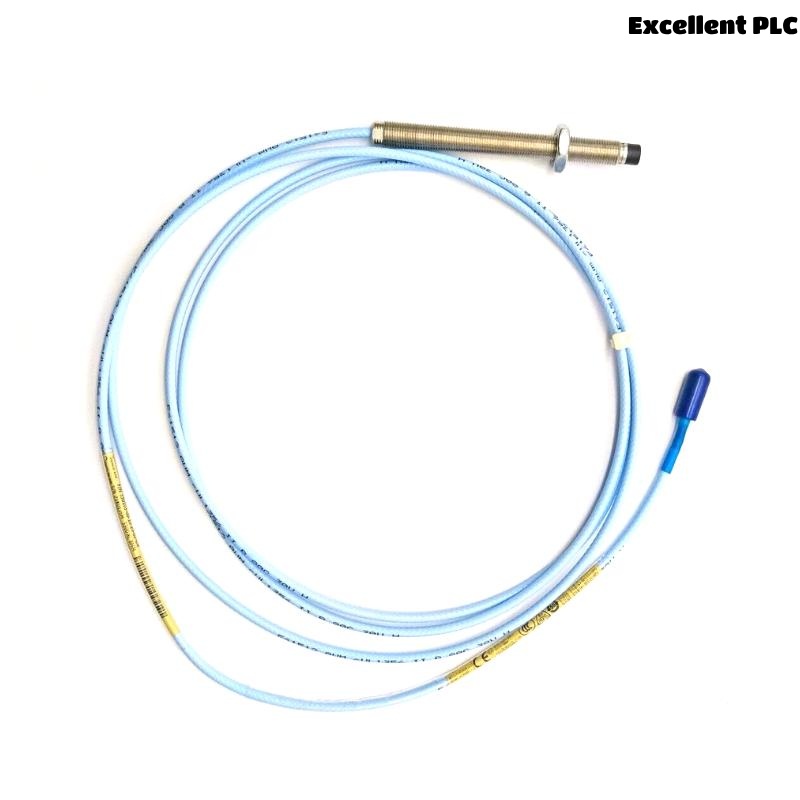

The Bently Nevada 330103-00-10-10-02-05 is a high-precision 8 mm proximity probe from the renowned 3300 XL series, designed to provide accurate and reliable measurement of shaft displacement and vibration in rotating machinery. This proximity probe is an integral part of Bently Nevada’s predictive maintenance solutions, offering real-time monitoring and early detection of potential machine failures. The 3300 XL series is well known for its robustness and exceptional performance in industrial settings.

The 330103-00-10-10-02-05 probe is engineered for use in high-performance machinery such as turbines, motors, and compressors. It is designed to meet the demanding requirements of industries that require precise vibration monitoring, including power generation, manufacturing, and heavy machinery operations. With its advanced features and reliable design, the 3300 XL 8 mm proximity probe helps extend the lifespan of critical equipment and reduce unplanned downtime.

Product Parameters

| Parameter | Value |

|---|---|

| Model Number | 330103-00-10-10-02-05 |

| Probe Type | 3300 XL 8 mm |

| Measurement Type | Proximity |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Diameter | 8 mm |

| Shaft Size | Compatible with shafts up to 150 mm in diameter |

| Output Type | DC Voltage |

| Cable Length | 1.0 meter |

| Operating Temperature | -40°C to +120°C |

| Mounting Type | Integral Mounting |

| Sensitivity | High Sensitivity |

| Protection Class | IP67 |

Applications

The Bently Nevada 330103-00-10-10-02-05 proximity probe is an essential tool for condition monitoring and vibration analysis in various industries. The probe’s applications include:

-

Rotating Machinery Monitoring: The probe is used to measure vibration and shaft displacement in turbines, compressors, motors, and other rotating machinery, ensuring smooth operation and detecting early signs of mechanical problems.

-

Predictive Maintenance: The probe plays a key role in predictive maintenance strategies, helping to detect abnormal vibrations or shaft displacements before they lead to equipment failure.

-

Industrial Process Monitoring: It is widely used in manufacturing plants, chemical industries, power plants, and other heavy industries where machinery reliability is crucial.

-

High-Speed Rotating Equipment: The probe is particularly effective for high-speed machinery, where precise vibration measurement is essential for maintaining system stability and preventing damage.

-

Condition-Based Monitoring Systems: Integrated into a broader vibration monitoring system, the probe helps monitor the health of equipment and detect any deviation from normal operating conditions, reducing unexpected downtime and repair costs.

Product Advantages

-

High-Precision Measurement: The 3300 XL 8 mm proximity probe provides extremely accurate and reliable measurements of vibrations and shaft displacement, allowing for early detection of issues and minimizing the risk of unplanned maintenance.

-

Robust and Reliable: Designed to withstand challenging industrial environments, the probe is highly durable, offering reliable performance even in harsh conditions such as high temperatures, moisture, and vibration.

-

Easy Integration: The probe is compatible with other Bently Nevada systems and integrates seamlessly into condition monitoring systems, enhancing overall machinery performance monitoring.

-

Enhanced Sensitivity: The high sensitivity of the 3300 XL probe ensures that even the smallest deviations in machinery behavior are detected, making it ideal for applications requiring early fault detection.

-

Long Service Life: Built with high-quality materials, the probe offers a long operational life, reducing the need for frequent replacements and maintenance.

-

Efficient Installation: The integral mounting design allows for easy and quick installation, minimizing downtime during setup and maintenance.

Frequently Asked Questions (FAQs)

-

What is the operating temperature range of the 3300 XL 8 mm proximity probe?

-

The probe operates within a wide temperature range of -40°C to +120°C, ensuring reliable performance in a variety of industrial environments.

-

-

How is the 3300 XL 8 mm proximity probe installed?

-

The probe features an integral mounting system, which simplifies installation and ensures it stays securely in place during operation.

-

-

What shaft sizes can the 3300 XL probe monitor?

-

The 3300 XL 8 mm proximity probe is compatible with shafts up to 150 mm in diameter, making it versatile for various applications.

-

-

Can the 3300 XL proximity probe be used in hazardous environments?

-

Yes, the probe is designed to perform reliably in harsh industrial environments, including those with exposure to high temperatures, vibrations, and moisture.

-

-

What type of output does the 3300 XL 8 mm proximity probe provide?

-

This probe produces a DC voltage output, which can be easily integrated with vibration monitoring systems.

-

-

Can the 3300 XL 8 mm proximity probe be used for continuous real-time monitoring?

-

Yes, it provides real-time feedback on machinery performance, allowing for continuous monitoring and immediate action when abnormal conditions are detected.

-

-

How does the 3300 XL 8 mm probe contribute to predictive maintenance?

-

By providing accurate measurements of shaft displacement and vibrations, the probe helps identify potential problems before they lead to failure, enabling predictive maintenance strategies.

-

-

What industries benefit the most from using the 3300 XL proximity probe?

-

The 3300 XL 8 mm proximity probe is widely used in industries such as power generation, petrochemicals, manufacturing, and heavy machinery, where equipment reliability is critical.

-

-

What is the sensitivity level of the 3300 XL proximity probe?

-

The probe is highly sensitive and can detect even minor vibrations and shaft displacements, making it ideal for detecting early signs of mechanical failure.

-

-

How do I maintain the 3300 XL proximity probe?

-

The probe requires minimal maintenance. Regular calibration and visual inspections are recommended to ensure it continues to perform optimally.

Related Models

| Model | Description |

|---|---|

| 330104-00-10-10-02-05 | 3300 XL 8 mm proximity probe with extended cable |

| 330103-00-10-10-02-01 | 3300 XL 8 mm proximity probe (standard configuration) |

| 330101-00-10-10-02-00 | 3300 XL 5 mm proximity probe |

| 330106-00-10-10-02-00 | 3300 XL 12 mm proximity probe |

| 330102-00-10-10-02-00 | 3300 XL 8 mm proximity probe with higher sensitivity |

| 330107-00-10-10-02-00 | 3300 XL 8 mm proximity probe with enhanced durability |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330500-00-01-10-00-00 | 3300 XL 8 mm vibration probe |

| 330350-00-01-00-00-00 | 3300 XL vibration monitoring system |

| 330420-00-01-01-01-00 | 3300 XL vibration transducer |

| 330400-00-02-10-02-00 | 3300 XL 10 mm proximity probe |

| 330101-00-01-10-00-00 | 3300 XL system with 5 mm probe |

| 350101-00-02-10-00-01 | 3500 vibration monitoring system |

Excellent PLC

Excellent PLC