| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Description

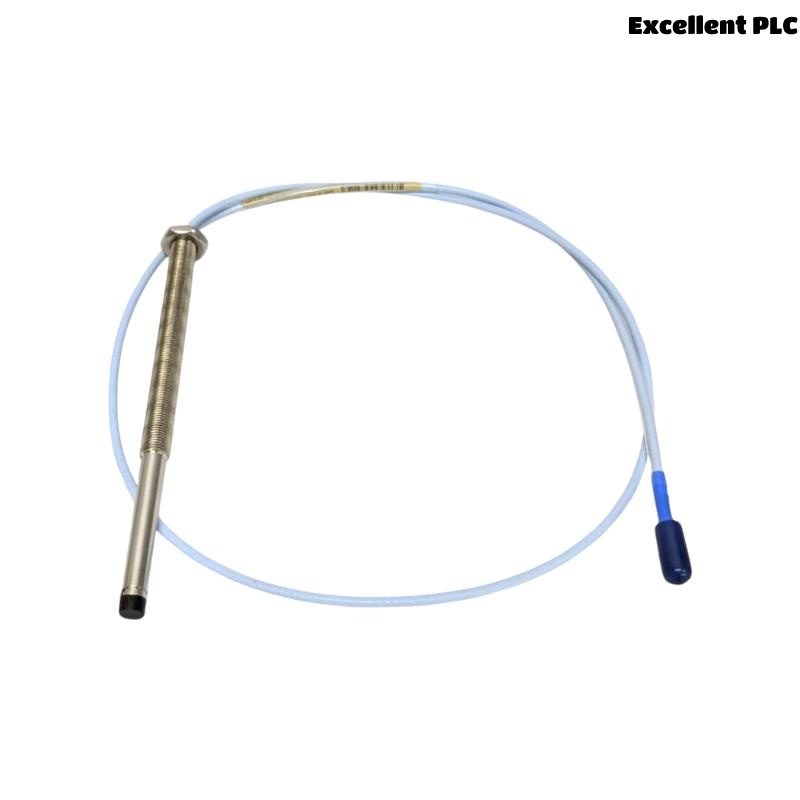

The Bently Nevada 330103-00-14-10-02-CN is a metric-threaded 3300 XL 8 mm Proximity Probe. It delivers precise measurements of vibration and shaft position in rotating machinery. As part of the 3300 XL system, it is compatible with XL and non-XL 3300 8 mm and 5 mm components, offering interchangeable installation without recalibration.

Applications

-

Vibration monitoring on fluid-film bearing machines

-

Shaft position and displacement measurement

-

Keyphasor reference and speed sensing

-

Use in harsh industrial environments, including high-temperature zones

Advantages

-

Fully compliant with API 670 standards

-

Robust PPS-molded tip and stainless-steel construction

-

Gold-plated ClickLoc connectors for reliable, tool-free connections

-

Extended temperature range options available

-

Backward and cross-compatible with earlier 3300 systems

Technical Specifications

| Parameter | Value |

|---|---|

| System Type | 3300 XL 8 mm |

| Thread Size | M10 x 1 |

| Probe Tip Material | PPS |

| Probe Body Material | Stainless Steel 303/304 |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Linear Range | 2 mm (80 mils) |

| Operating Temperature | -52°C to +177°C (standard) |

| Extended Temp (Optional) | up to +218°C |

| Frequency Response | 0 to 10 kHz |

| Recommended Shaft Diameter | ≥76.2 mm (3 in) |

| Minimum Target Size | 15.2 mm |

| Connector Type | ClickLoc miniature coaxial |

| Cable Type | 75Ω triaxial |

FAQ

Q1: Is the 330103 compatible with older 3300 systems?

A1: Yes, it is backward and cross-compatible with non-XL 3300 8 mm and 5 mm components.

Q2: What is the recommended gap setting?

A2: Approximately 1.27 mm (50 mils) corresponding to -9 Vdc.

Q3: Can this probe operate in high-temperature environments?

A3: Yes, the standard probe supports up to 177°C, and extended temperature versions are rated up to 218°C.

Q4: Does the probe require calibration before installation?

A4: No, probes are factory-calibrated and fully interchangeable without the need for field calibration.

Q5: What is the advantage of ClickLoc connectors?

A5: They ensure secure, corrosion-resistant connections without tools and prevent loosening.

Q6: What is the minimum recommended shaft diameter for accurate measurements?

A6: At least 76.2 mm (3 inches) for optimal performance.

Q7: How resistant is the probe to oil ingress?

A7: Optional FluidLoc cables prevent oil from leaking through the cable interior.

Q8: What certifications does the probe meet?

A8: Complies with API 670, FCC Part 15, CE mark (EMC/RoHS), and ATEX/IECEx hazardous area certifications.

Q9: Is an armored version available?

A9: Yes, armored and non-armored versions are available depending on application needs.

Q10: What is the maximum recommended torque when installing the probe?

A10: Standard M10x1 probes recommend 7.5 N•m (66 in•lbf) torque.

Recommended Related Models

| Model Number | Description | Total Length | Weight |

|---|---|---|---|

| 330101-00-08-10-02 | 8 mm UNF-thread probe, unarmored | 1.0 m | 0.323 kg |

| 330102-00-08-10-02 | 8 mm UNF-thread probe, armored | 1.0 m | 0.340 kg |

| 330104-00-06-10-02 | 8 mm M10-thread probe, armored | 1.0 m | 0.340 kg |

| 330105-02-12-10-02 | 8 mm UNF-thread reverse mount | 1.0 m | 0.323 kg |

| 330140-00-08-10-02 | 8 mm smooth case probe, unarmored | 1.0 m | 0.323 kg |

| 330191-00-08-10-02 | 8 mm UNF-thread ETR probe, unarmored | 1.0 m | 0.323 kg |

Popular Bently Nevada Models

| Model Number | Description | Total Length | Weight |

|---|---|---|---|

| 330180-01-00 | Proximitor Sensor, panel mount | 1.0 m | 0.246 kg |

| 330104-00-06-10-02 | 8 mm M10-thread probe, armored | 1.0 m | 0.340 kg |

| 3500/42M-01-00 | Proximitor Seismic Monitor | — | 1.5 kg |

| 3500/44M-02-00 | Aeroderivative GT Vibration Monitor | — | 1.7 kg |

| 330130-03-00 | Standard extension cable, 3 m | 3.0 m | 0.102 kg |

| 3500/22M-01-00 | Transient Data Interface Module | — | 1.8 kg |

Excellent PLC

Excellent PLC