| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

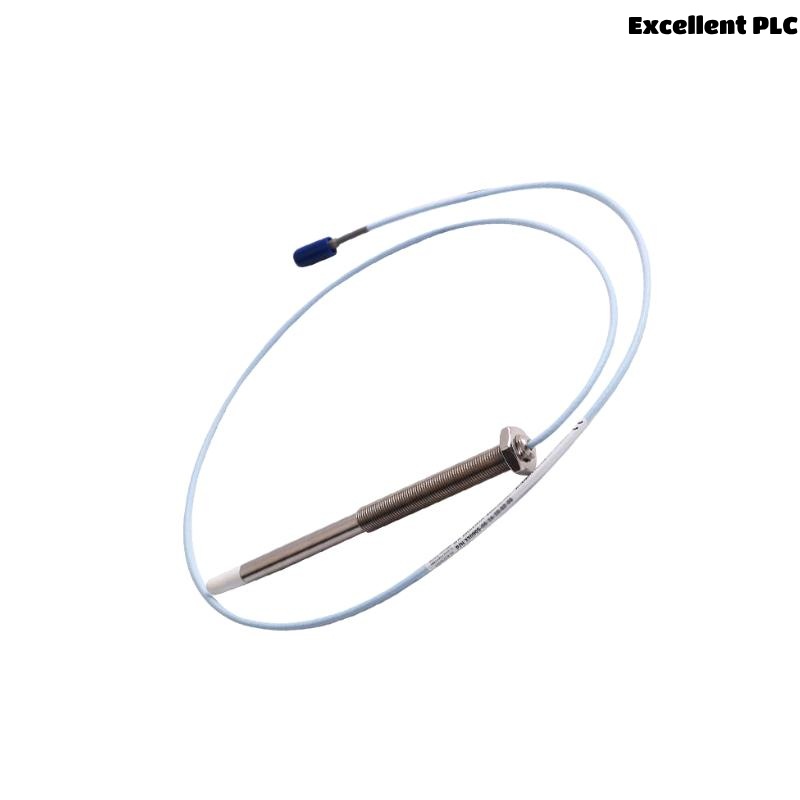

The Bently Nevada 330103-00-15-10-02-00 is a robust and precise proximity probe from the highly trusted 3300 XL series. Designed to monitor critical rotating machinery components, this probe uses eddy current technology to provide accurate, non-contact measurement of shaft displacement and vibration. Featuring an 8mm probe tip diameter and a 1 meter integral cable, this model is engineered to meet demanding industrial environments where reliable and continuous condition monitoring is essential.

The 3300 XL series probes are widely deployed in industries such as power generation, oil and gas, petrochemical, and heavy manufacturing. Their rugged stainless steel construction and proven performance make them a go-to solution for machinery health monitoring to prevent unplanned outages and costly repairs. This model balances ease of installation with high precision, providing a dependable signal even in harsh operational conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330103-00-15-10-02-00 |

| Probe Tip Diameter | 8 mm |

| Cable Length | 1 meter |

| Probe Type | Eddy current proximity probe |

| Operating Temperature Range | -40°C to +120°C |

| Probe Body Material | Stainless steel |

| Connector Type | Integral cable |

| Weight | 0.323 kg |

| Frequency Response | DC to 25 kHz |

| Measuring Range | Up to 1.5 mm (application dependent) |

| Electrical Interface | 2-wire shielded cable |

Applications

-

Steam and Gas Turbines: Critical for shaft vibration and position monitoring, preventing damage from imbalance or misalignment.

-

Compressors: Detects subtle shaft displacements to help identify bearing faults and mechanical looseness early.

-

Generators: Monitors rotor movement to ensure smooth and safe operation.

-

Centrifugal Pumps: Tracks axial and radial shaft movements to prevent unexpected pump failures.

-

Motors and Gearboxes: Used for predictive maintenance by monitoring vibration signatures and shaft displacement.

-

Heavy Industrial Equipment: Commonly applied across oil refineries, chemical plants, and manufacturing facilities for machine health management.

Product Advantages

-

High Accuracy: 8mm probe tip diameter enables precise detection of small shaft displacements.

-

Long Cable Length: 1 meter of integrated cable facilitates versatile and convenient installation.

-

Durable Design: Stainless steel body ensures resistance to corrosion, dust, and moisture in industrial environments.

-

Wide Operating Temperature: Reliable function in a broad temperature range from -40°C to +120°C.

-

Non-Contact Measurement: Eddy current technology allows wear-free operation with minimal maintenance.

-

Stable Signal: Designed to maintain high signal integrity for consistent monitoring results.

-

Ease of Integration: Compatible with Bently Nevada 3300 series monitors and many other vibration monitoring systems.

-

Low Maintenance: Robust build and non-contact sensing reduce the frequency of maintenance and calibration.

-

Industry Standard: Trusted worldwide for critical machine protection and condition monitoring.

Frequently Asked Questions (FAQ)

-

What does the Bently Nevada 330103-00-15-10-02-00 measure?

It measures shaft displacement and vibration through non-contact eddy current sensing. -

Is the 1 meter cable replaceable?

No, the cable is integral to the probe, but custom cable lengths can be specified when ordering. -

What temperature ranges is this probe rated for?

It operates reliably between -40°C and +120°C. -

In which industries is this probe commonly used?

Power generation, petrochemical, oil and gas, and heavy manufacturing industries. -

What is the typical measuring range for this probe?

Up to 1.5 mm, depending on installation and system configuration. -

How does this probe connect to monitoring equipment?

Via a two-wire shielded cable designed for compatibility with 3300 series and other vibration monitors. -

How resistant is the probe to harsh environments?

The stainless steel construction provides excellent protection against dust, moisture, and mild chemicals. -

How frequently should the probe be inspected?

Regular inspections during planned maintenance shutdowns are advised to ensure optimal performance. -

Can the probe detect both axial and radial shaft movements?

Yes, depending on the installation configuration and the number of probes used. -

What maintenance is required for this probe?

Minimal maintenance is required due to the non-contact design, but periodic checks and cleaning are recommended.

Recommended Related Models (Same Series or Similar)

| Model Number | Probe Tip Diameter | Cable Length | Notes |

|---|---|---|---|

| 330103-00-13-05-02-00 | 8 mm | 5 meters | Standard length cable |

| 330103-00-13-20-02-00 | 8 mm | 20 meters | Extended cable length |

| 330103-00-11-05-02-00 | 5 mm | 5 meters | Smaller tip for tight spaces |

| 330103-00-13-05-03-00 | 8 mm | 3 meters | Short cable for compact setups |

| 330103-00-12-10-02-00 | 12 mm | 10 meters | Larger tip for heavy equipment |

| 330103-00-13-10-03-00 | 8 mm | 10 meters | Alternate cable configuration |

Popular Bently Nevada Models (Same Brand)

| Model Number | Description | Application |

|---|---|---|

| 330130-00-40-00-00-00 | 3300 XL Monitor | Vibration and proximity monitoring system |

| 330103-00-12-10-02-CN | 8 mm probe, 10m cable | Heavy industrial applications |

| 330108-00-04-05-02-00 | 5 mm probe, 5m cable | General machinery monitoring |

| 330090-00-03-05-00-00 | Replacement sensor cable | Spare part |

| 330199-00-01-00-00-00 | Proximitor Sensor Module | Signal conditioning |

| 330103-00-13-05-02-01 | 8 mm probe, 5m cable with temp rating | High-temperature applications |

Excellent PLC

Excellent PLC