| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Description

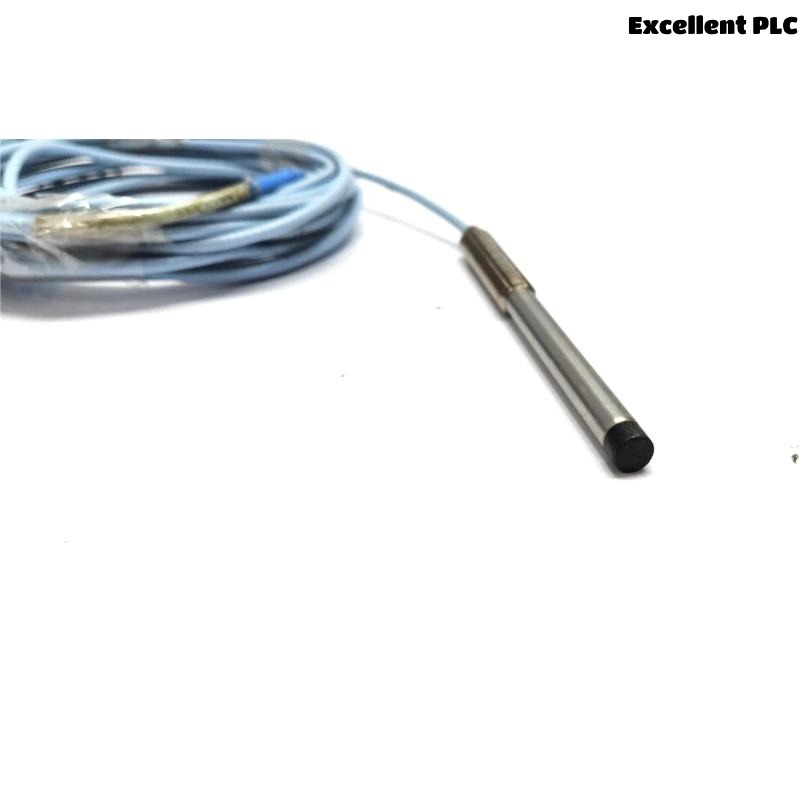

The Bently Nevada 330103-00-15-10-02-05 is part of the 3300 XL 8 mm Proximity Transducer System. It delivers accurate static and dynamic measurements of position and vibration on rotating machinery with fluid-film bearings. This metric-thread probe, paired with an extension cable and Proximitor sensor, ensures compliance with API 670 standards and features advanced EMI immunity, robust construction, and full component interchangeability.

Technical Specifications

| Parameter | Value |

|---|---|

| Probe Tip Diameter | 8 mm |

| Thread Type | M10 x 1 |

| Total Length | 1.0 meter (3.3 feet) |

| Weight | 0.323 kg |

| Linear Range | 0.25 mm – 2.3 mm (10–90 mils) |

| Operating Temperature | -52°C to +177°C (standard probe) |

| Max Pressure Seal | Viton O-ring (not pressure tested) |

| Cable Type | FEP insulated triaxial, optional FluidLoc |

| Material (Probe Case) | Stainless Steel AISI 303/304 |

| Material (Tip) | Polyphenylene sulfide (PPS) |

Applications

-

Vibration and position monitoring on fluid-film bearing machinery

-

Keyphasor reference and overspeed measurements

-

High-temperature and harsh industrial environments

Advantages

-

Meets API 670 requirements

-

High immunity to EMI and RFI

-

Robust, patented TipLoc and CableLoc designs

-

Fully interchangeable components

-

Extended temperature range options

-

Easy field wiring with SpringLoc connectors

FAQ

Q1: What is the primary use of this proximity probe?

A1: It is used for precise position and vibration monitoring in rotating machinery.

Q2: Does it meet API 670 standards?

A2: Yes, it fully complies with API 670 standards for accuracy and linearity.

Q3: Can the components be mixed with older non-XL systems?

A3: Yes, but system performance will be limited to the non-XL specifications.

Q4: What is the maximum operating temperature of the standard probe?

A4: +177°C for the standard probe tip.

Q5: Is it resistant to radio frequency interference?

A5: Yes, the design ensures high immunity to RFI and EMI.

Q6: What is the recommended shaft diameter for accurate measurements?

A6: At least 50.8 mm (2 inches), with 76.2 mm (3 inches) recommended.

Q7: Does the probe come with armored cable?

A7: This specific model is without armor but armored versions are available.

Q8: How is the cable protected against oil leakage?

A8: Optional FluidLoc cable prevents oil from leaking through the cable.

Q9: What is the weight of the 1-meter probe?

A9: Approximately 0.323 kg.

Q10: Are connector protectors included?

A10: No, they are optional and recommended for added environmental protection.

Recommended Related Models

| Model | Description | Length | Weight |

|---|---|---|---|

| 330103-00-10-10-02-05 | 8 mm M10x1 probe, 1.0 m, no armor | 1.0 m | 0.323 kg |

| 330103-00-20-10-02-05 | 8 mm M10x1 probe, 2.0 m, no armor | 2.0 m | 0.400 kg |

| 330103-00-15-10-11-05 | 8 mm M10x1 probe, 1.5 m, FluidLoc cable | 1.5 m | 0.360 kg |

| 330104-00-15-10-02-05 | 8 mm M10x1 probe, 1.5 m, armored | 1.5 m | 0.380 kg |

| 330103-00-05-10-02-05 | 8 mm M10x1 probe, 0.5 m, no armor | 0.5 m | 0.300 kg |

| 330104-00-10-10-02-05 | 8 mm M10x1 probe, 1.0 m, armored | 1.0 m | 0.340 kg |

Popular Bently Nevada Models

| Model | Description | Length | Weight |

|---|---|---|---|

| 330101-00-10-10-02-05 | 8 mm 3/8-24 UNF probe, 1.0 m, no armor | 1.0 m | 0.323 kg |

| 330104-00-20-10-02-05 | 8 mm M10x1 probe, 2.0 m, armored | 2.0 m | 0.400 kg |

| 330105-02-12-10-02-05 | 8 mm reverse-mount probe, 1.0 m | 1.0 m | 0.323 kg |

| 330106-05-30-10-02-05 | 8 mm reverse-mount probe M10x1, 1.0 m | 1.0 m | 0.323 kg |

| 330140-00-10-10-02-05 | 8 mm smooth-case probe, 1.0 m | 1.0 m | 0.323 kg |

| 330180-11-00 | Proximitor Sensor, 1.0 m, DIN mount | 1.0 m | 0.246 kg |

Excellent PLC

Excellent PLC