| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

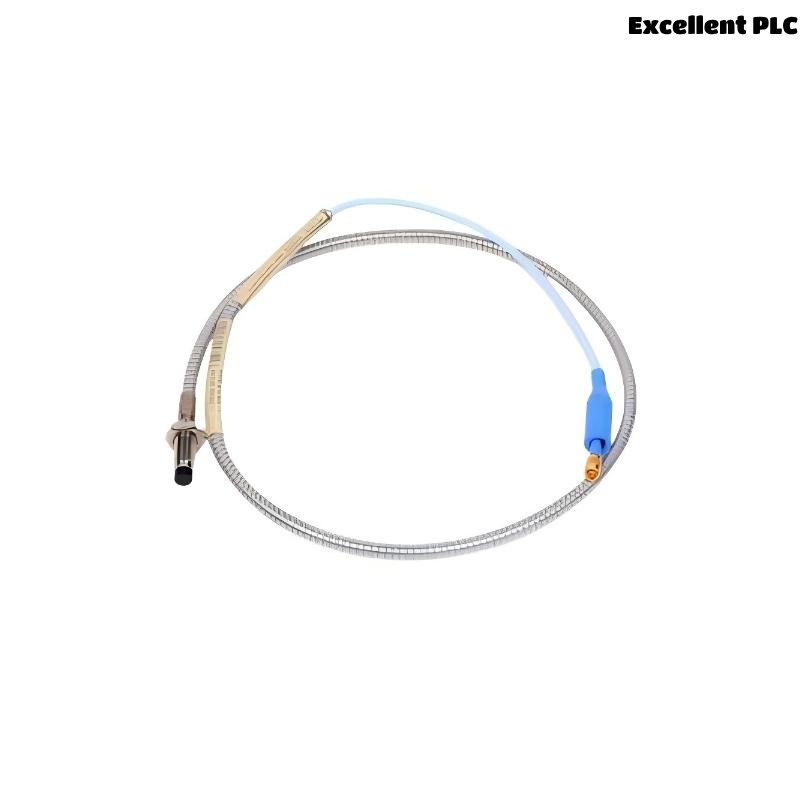

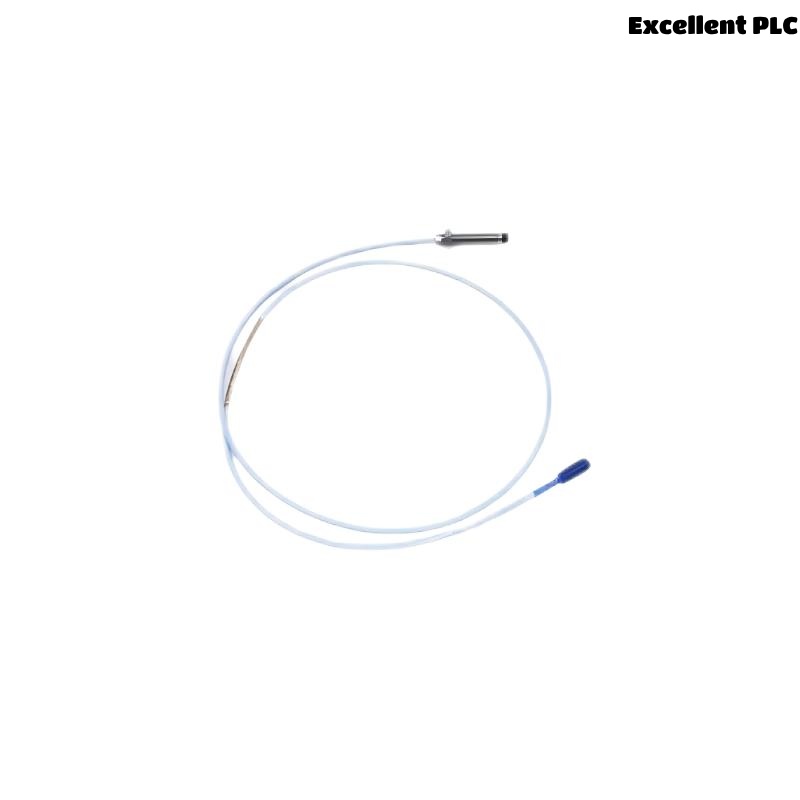

The Bently Nevada 330103-01-06-05-02-05 8 mm proximity probe is a key component of the 3300 XL Series, designed for accurate measurement of displacement and vibration in critical machinery. With its eddy current technology, this non-contact probe provides high-precision measurements for detecting mechanical faults such as misalignment and imbalance. This probe is ideal for monitoring machinery that requires continuous condition assessment, making it an essential tool for predictive maintenance in industries like power generation, oil & gas, and manufacturing.

Measuring 0.5 meters in total length and weighing 0.161 kg, this probe is lightweight, easy to install, and capable of providing continuous monitoring of rotating machinery. It is designed to detect even the smallest changes in displacement, which helps to prevent costly repairs and unexpected downtime by allowing for timely maintenance actions.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330103-01-06-05-02-05 |

| Type | 8 mm Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Shaft Diameter | 8 mm |

| Operating Temperature | -40°C to +120°C |

| Range | 1-25 mil (0.0254-0.635 mm) |

| Mounting Type | Direct Mount |

| Measurement Principle | Eddy Current |

| Cable Length | 0.5 meter |

| Accuracy | ± 0.001 inch (± 0.0254 mm) |

Product Applications

The 330103-01-06-05-02-05 8 mm proximity probe is widely used across several industries where machinery condition monitoring is critical:

-

Power Generation: The probe is used to monitor turbines, compressors, and generators, helping prevent unplanned shutdowns by detecting misalignment and imbalance early.

-

Oil & Gas: In offshore rigs and refineries, the probe is vital for continuous monitoring of equipment like pumps and compressors, ensuring smooth operation and reducing downtime.

-

Manufacturing: In factory settings, the probe monitors motors, pumps, and conveyor belts, allowing operators to identify potential problems before they affect production.

-

Marine: Ships and offshore platforms use this probe for monitoring engine performance, avoiding failures that could result in costly repairs or operational delays.

-

Aerospace: The probe is utilized in turbine engines, ensuring that vibrations and displacements are within safe operating limits, preventing damage to mission-critical components.

-

Transportation: For trains, aircraft engines, and automotive production lines, the probe ensures that key components operate at peak efficiency by monitoring their vibration and displacement.

Product Advantages

-

High Precision: The 330103-01-06-05-02-05 probe offers ± 0.001 inch (± 0.0254 mm) accuracy, ensuring highly reliable measurements, critical for machinery monitoring in industries where safety is paramount.

-

Wide Temperature Range: With an operating temperature range from -40°C to +120°C, the probe can function effectively in extreme conditions, making it versatile for use in diverse environments.

-

Non-Contact Measurement: The eddy current technology allows for non-contact measurement, reducing wear and tear on both the probe and the machinery being monitored, increasing the lifespan of both.

-

Real-Time Data: Continuous, real-time monitoring provides immediate feedback on equipment health, enabling operators to detect issues before they lead to failures.

-

Durability: The probe’s rugged design and high-quality materials make it durable enough to withstand harsh environments, ensuring long-term performance with minimal maintenance.

-

Cost-Effective: By identifying problems early, the probe helps reduce unexpected downtime and costly repairs, making it a cost-effective solution for predictive maintenance.

-

Easy to Install: Weighing only 0.161 kg and with a total length of 0.5 meters, the probe is easy to install and maintain, even in tight spaces or challenging installation environments.

-

Enhanced Reliability: By monitoring vibration and displacement, the probe helps ensure that machines are running within safe limits, thus enhancing the overall reliability and efficiency of the machinery.

-

Preventative Maintenance: The probe’s ability to detect even minor displacement and vibration changes makes it an invaluable tool for implementing preventative maintenance programs.

-

Industry Versatility: Suitable for a wide range of industries, the 330103-01-06-05-02-05 probe is ideal for use in power generation, manufacturing, oil & gas, and more, making it a flexible solution for many applications.

Frequently Asked Questions (FAQ)

Q1: What is the technology used in the 330103-01-06-05-02-05 probe?

A1: The 330103-01-06-05-02-05 uses eddy current technology for non-contact measurement of displacement and vibration, which ensures accuracy and prevents mechanical wear.

Q2: What is the accuracy of the 330103-01-06-05-02-05 probe?

A2: The probe offers an accuracy of ± 0.001 inch (± 0.0254 mm), providing highly precise measurements for machinery monitoring.

Q3: What is the total length of the 330103-01-06-05-02-05 probe?

A3: The total length of the probe is 0.5 meters, making it suitable for a variety of applications.

Q4: How much does the 330103-01-06-05-02-05 probe weigh?

A4: The probe weighs 0.161 kg, which makes it lightweight and easy to handle during installation and maintenance.

Q5: What is the operating temperature range for this probe?

A5: The probe can operate in temperatures ranging from -40°C to +120°C, allowing it to function in harsh industrial environments.

Q6: How does the 330103-01-06-05-02-05 probe help with predictive maintenance?

A6: By continuously monitoring vibration and displacement, the probe detects early signs of potential faults, enabling predictive maintenance and reducing unexpected downtime.

Q7: What is the range of the 330103-01-06-05-02-05 probe?

A7: The probe has a range of 1-25 mil (0.0254-0.635 mm), which allows it to measure even slight changes in displacement and vibration.

Q8: Can this probe be used with other monitoring systems?

A8: While it is designed for use with the 3300 XL vibration monitoring system, it can also be integrated with other systems that support eddy current measurement technology.

Q9: What kind of machines can the 330103-01-06-05-02-05 probe monitor?

A9: The probe is ideal for monitoring turbines, generators, pumps, motors, and other rotating machinery.

Q10: How does non-contact measurement benefit this probe?

A10: Non-contact measurement minimizes wear on both the probe and the machinery being monitored, resulting in fewer maintenance requirements and a longer lifespan for both.

Recommended Related Models (Same Series or Related)

| Model | Description | Range | Accuracy | Mounting |

|---|---|---|---|---|

| 330103-01-06-05-02-01 | Extended range 8 mm proximity probe | 1-50 mil (0.0254-1.27 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-06-05-02-02 | High temperature 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-06-05-02-03 | 8 mm proximity probe with extended cable | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-06-05-02-04 | Hazardous area 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-06-05-02-05 | 8 mm proximity probe for aerospace applications | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-06-05-02-06 | Custom length 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

Recommended Popular Models from Bently Nevada

| Model Number | Parameters | Application | Advantages |

|---|---|---|---|

| 330103-00-08-10-01-00 | 24V, 10A, 1-wire | Vibration Monitoring | High accuracy, reliable performance |

| 330103-00-08-10-02-00 | 24V, 12A, 2-wire | Industrial Control Systems | Durable, flexible, high efficiency |

| 330103-00-08-10-03-00 | 24V, 15A, 3-wire | Process Control | High power output, stable operation |

| 330103-00-08-10-04-00 | 24V, 18A, 1-wire | Motor Control Systems | Robust design, efficient performance |

| 330103-00-08-10-05-00 | 24V, 20A, 2-wire | Power Distribution Systems | Reliable, long-lasting, cost-effective |

| 330103-00-08-10-06-00 | 24V, 25A, 3-wire | Automation Systems | High efficiency, versatile integration |

Excellent PLC

Excellent PLC