| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

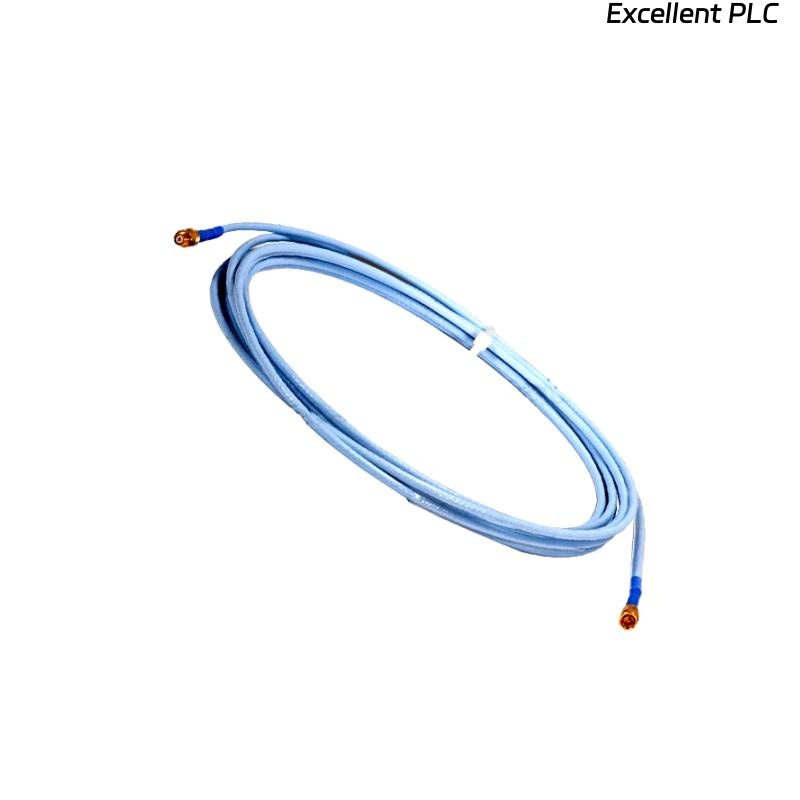

The Bently Nevada 330103-02-04-10-02 3300 XL 8mm Proximity Probe is a high-precision sensor designed for monitoring shaft vibration and displacement in critical rotating machinery. Part of the trusted 3300 XL series, it delivers reliable and accurate measurements essential for machinery protection, performance optimization, and predictive maintenance programs.

Utilizing eddy current technology, this probe converts the mechanical displacement of a rotating shaft into a precise electrical signal. Its 1-meter length and 0.323 kg weight make it suitable for installations requiring medium-length connections, ensuring stable signal transmission and convenient handling. The probe’s robust stainless steel housing offers excellent protection against corrosion and harsh industrial conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330103-02-04-10-02 |

| Series | 3300 XL 8mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 meter |

| Weight | 0.323 kg |

| Connector Type | Standard coaxial connector |

| Housing Material | Corrosion-resistant stainless steel |

| Frequency Response | DC to 10 kHz |

| Linear Measurement Range | 2 mm (typical when paired with Proximitor sensor) |

| Nominal Gap | 2 mm |

| Operating Temperature Range | –35 °C to +180 °C |

| Humidity Tolerance | Up to 95% non-condensing |

| Shock Tolerance | 500 g, 1 ms half-sine |

| Vibration Tolerance | 10 g, 10–2000 Hz |

| Compliance | API 670 compliant |

Applications

The 330103-02-04-10-02 probe is widely deployed in condition monitoring and machinery protection. Its main applications include:

-

Monitoring radial vibration in turbines, compressors, pumps, and generators.

-

Measuring axial shaft displacement to prevent mechanical overload.

-

Providing signals for predictive maintenance and early fault detection.

-

Integration in power plants, petrochemical plants, and oil & gas facilities.

-

Medium-range installations where a 1-meter probe cable is optimal.

-

Detecting mechanical issues such as imbalance, misalignment, and shaft looseness.

Advantages

-

High Measurement Accuracy: Provides precise and repeatable displacement and vibration readings.

-

Moderate Cable Length: 1-meter cable offers flexibility for medium-distance installations.

-

Durable Construction: Stainless steel housing resists corrosion, shock, and vibration.

-

Thermal Stability: Performs reliably across –35 °C to +180 °C.

-

API 670 Compliance: Conforms to industry standards for machinery protection.

-

System Compatibility: Integrates seamlessly with 3300 XL Proximitor sensors and monitoring systems.

-

Noise Reduction: Shielded cable ensures minimal electromagnetic interference.

-

Interchangeable Design: Can replace other 3300 XL 8mm probes without recalibration.

FAQ

1. What sensing principle does this probe use?

It uses eddy current technology to detect the distance between the probe tip and the rotating shaft.

2. What is the linear measurement range?

The typical linear range is 2 mm when used with a matching Proximitor sensor.

3. How does the 1-meter cable affect calibration?

The probe and cable are factory-matched, ensuring calibration accuracy over the 1-meter length.

4. Can it monitor both radial and axial shaft movement?

Yes, it can measure radial vibration and axial displacement depending on installation orientation.

5. What type of electrical output does the probe provide?

It generates a voltage signal proportional to shaft displacement.

6. How does it handle electromagnetic interference?

The probe has shielding to minimize EMI, maintaining signal integrity in electrically noisy environments.

7. Is it suitable for hazardous or classified areas?

Yes, when installed with certified Proximitor sensors following proper safety protocols.

8. What temperature range does it operate in?

It operates reliably from –35 °C to +180 °C.

9. Can it be used with legacy Bently Nevada monitoring systems?

Yes, it is compatible with 3300 and 3500 series monitoring modules.

10. What standards does this probe comply with?

It complies with API 670 for vibration and displacement monitoring in rotating machinery.

Recommended Related Models (Same Series / Family)

| Model Number | Description |

|---|---|

| 330103-00-12-05-12-00 | 3300 XL 8mm probe, 0.5 m cable |

| 330103-00-12-50-02-00 | 3300 XL 8mm probe, 5 m cable |

| 330103-00-13-10-12-RU | 3300 XL 8mm probe, 1 m RU compliant |

| 330103-00-13-50-12-RU | 3300 XL 8mm probe, 5 m RU compliant |

| 330103-00-14-05-02-05 | 3300 XL 8mm probe, 0.5 m cable |

| 330104-00-10-05-02-00 | 3300 XL 11 mm probe, extended linear range |

Popular Bently Nevada Models (Other Hot Products)

| Model Number | Description |

|---|---|

| 330130-040-00 | 3300 XL 11 mm Proximity Probe |

| 330180-91-05 | 3300 XL Proximitor Sensor |

| 330400-50-05 | Velomitor® XA Vibration Sensor |

| 330850-90-05 | High-Temperature Velocity Sensor |

| 3500/22M | 3500 System Communications Module |

| 3500/42M | Proximitor/Seismic Monitor |

Excellent PLC

Excellent PLC