| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

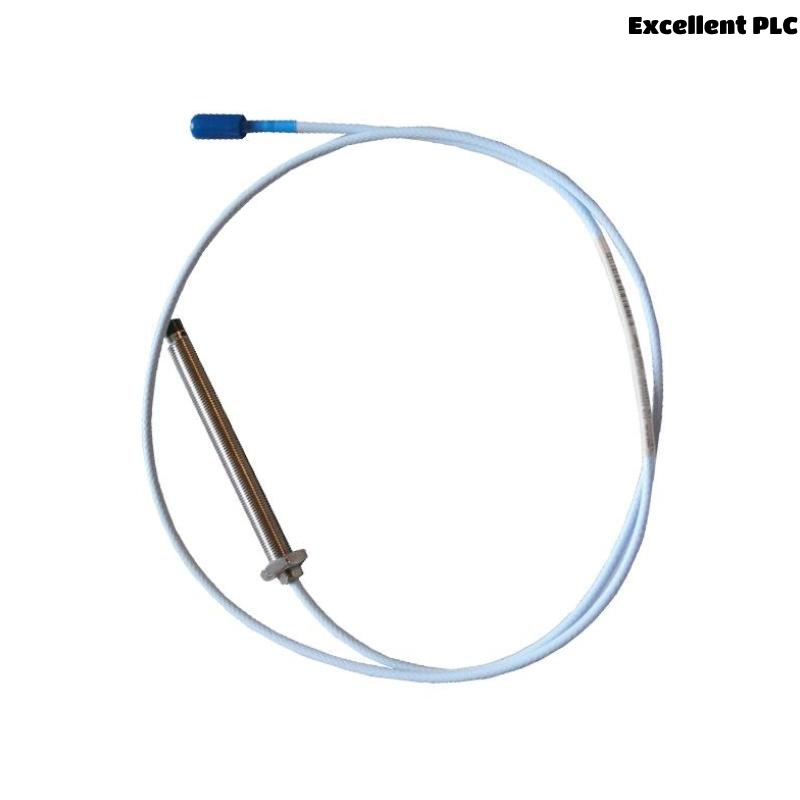

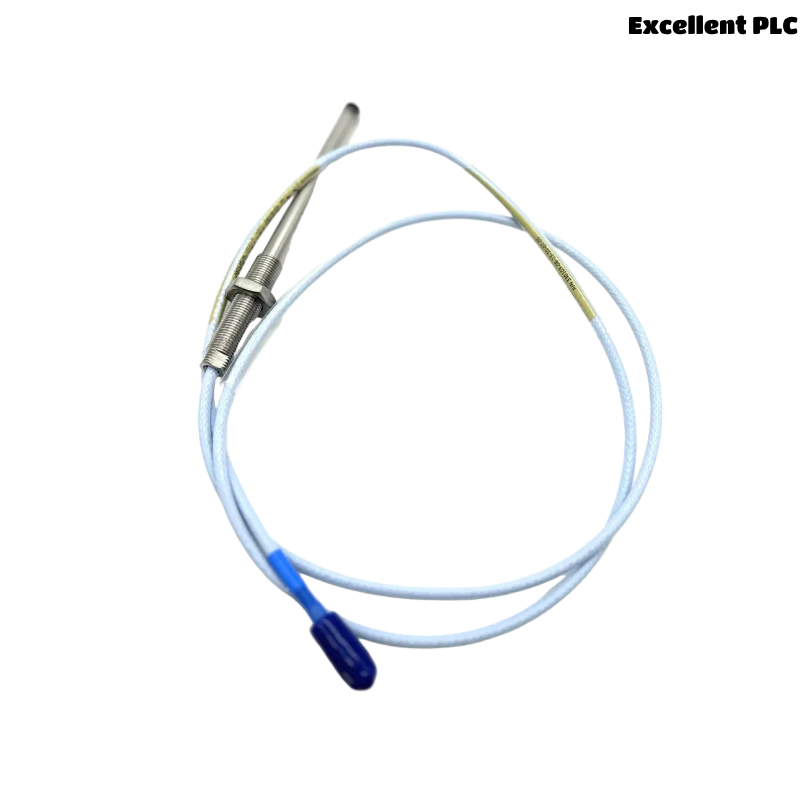

Product Overview: Bently Nevada 330103-02-17-05-02-CN

The Bently Nevada 330103-02-17-05-02-CN is a highly reliable vibration sensor used for continuous monitoring and protection of rotating machinery in industrial environments. It forms part of the Bently Nevada machinery protection system, specifically designed to detect and measure vibration levels, which is critical in preventing equipment failure and ensuring optimal machine performance. This sensor is engineered to meet the stringent needs of industries such as oil & gas, power generation, mining, and manufacturing, where machinery reliability is paramount.

The sensor is a key part of a predictive maintenance strategy, where it helps in identifying potential issues before they cause significant damage. With its high precision and durability, the 330103-02-17-05-02-CN sensor is capable of providing real-time data, which is crucial for maintaining the smooth operation of critical systems. It offers flexibility in terms of compatibility and can be integrated into most industrial control systems with ease.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330103-02-17-05-02-CN |

| Sensor Type | Vibration Sensor |

| Mounting Type | 2-Wire, Vibration Transducer |

| Cable length | 0.5 m |

| Weight | 0.162 kg |

| Operating Voltage | 24V DC |

| Frequency Range | 10 Hz to 10 kHz |

| Operating Temperature | -40°C to 85°C |

| Output Signal | 4-20 mA |

| IP Rating | IP67 |

| Measurement Range | 0.01 to 50 mm/s vibration velocity |

| Response Time | < 2 ms |

Applications

The Bently Nevada 330103-02-17-05-02-CN vibration sensor is used extensively across various industries where machinery reliability and performance are critical. Some of its major applications include:

-

Rotating Equipment Monitoring: Used in power plants, oil refineries, and manufacturing facilities to monitor pumps, motors, compressors, and turbines.

-

Predictive Maintenance: Helps in assessing equipment condition and predicting potential failure before it occurs, thus enabling cost-effective maintenance.

-

Condition Monitoring Systems: Ideal for integration into plant-wide condition monitoring systems that focus on early fault detection and minimization of unplanned downtime.

-

Automation Systems: Compatible with control systems for real-time monitoring and control of machinery operations.

-

Quality Assurance in Production Lines: Monitors machinery health and ensures consistent production quality in heavy industries.

Advantages

-

Reliability: Known for its durable design, the sensor can withstand harsh environmental conditions and operate with high reliability in challenging industrial settings.

-

Precision: It provides accurate, real-time data with a wide frequency range for high-resolution vibration measurements.

-

Easy Integration: The sensor seamlessly integrates with existing machinery protection and control systems.

-

Predictive Maintenance Capabilities: By providing real-time vibration data, it allows for proactive equipment maintenance, reducing unexpected downtime and costly repairs.

-

Low Power Consumption: The device operates on a 24V DC supply, making it suitable for power-sensitive applications.

-

Robustness: With an IP67 rating, the sensor is resistant to dust and water, ensuring optimal performance even in adverse conditions.

FAQs (Frequently Asked Questions)

1. What is the purpose of the Bently Nevada 330103-02-17-05-02-CN vibration sensor?

The Bently Nevada 330103-02-17-05-02-CN sensor is used for continuous monitoring of machinery vibrations to detect any abnormalities that might indicate potential failures. This helps in preventing downtime and expensive repairs by enabling predictive maintenance.

2. How is the sensor mounted on the equipment?

The sensor is mounted using a 2-wire setup that connects to the equipment where vibration monitoring is needed. It is typically mounted on rotating equipment like motors, pumps, and turbines.

3. What is the frequency range of the Bently Nevada 330103-02-17-05-02-CN sensor?

The sensor has a frequency range of 10 Hz to 10 kHz, allowing it to capture both low and high-frequency vibrations.

4. How does the sensor output data?

The sensor outputs a 4-20 mA signal, which is compatible with most industrial control systems for real-time monitoring.

5. What is the operating temperature range of the sensor?

The sensor operates efficiently within a temperature range of -40°C to 85°C, making it suitable for use in extreme industrial environments.

6. Can the sensor be used in explosive environments?

The sensor is not intrinsically safe or designed for use in explosive atmospheres. However, it can be used in most industrial settings where vibration monitoring is required.

7. What is the lifespan of the Bently Nevada 330103-02-17-05-02-CN sensor?

The sensor is designed to last for several years under normal operating conditions. Regular maintenance and inspection will ensure its optimal performance throughout its lifespan.

8. Can this sensor be used for monitoring multiple machines at once?

Yes, the sensor can be integrated into a broader machinery condition monitoring system to monitor multiple machines simultaneously.

9. Is the sensor compatible with other Bently Nevada products?

Yes, the sensor is fully compatible with other Bently Nevada monitoring and control products, allowing for an integrated solution for machinery health monitoring.

10. How does the Bently Nevada 330103-02-17-05-02-CN help in predictive maintenance?

By monitoring vibration levels in real-time, the sensor helps identify potential issues such as misalignment or unbalanced machinery before they lead to failure, enabling early intervention and minimizing downtime.

Related Models from the Same Series or Similar Models

| Model | Description | Vibration Measurement Range | Weight | Output Signal |

|---|---|---|---|---|

| 330103-02-17-05-02-00 | Vibration sensor with similar specs | 0.01 to 50 mm/s | 1.6 kg | 4-20 mA |

| 330103-02-17-01-02-00 | Vibration sensor with lower range | 0.01 to 10 mm/s | 1.5 kg | 4-20 mA |

| 330103-02-17-05-02-01 | Advanced vibration sensor model | 0.01 to 100 mm/s | 2.0 kg | 4-20 mA |

| 330103-02-17-06-02-00 | Vibration sensor with high frequency | 10 Hz to 20 kHz | 1.8 kg | 4-20 mA |

| 330103-02-17-07-02-00 | Vibration sensor with extended temperature range | -50°C to 100°C | 2.2 kg | 4-20 mA |

| 330103-02-17-05-02-03 | Vibration sensor for heavy-duty industrial machines | 0.01 to 75 mm/s | 2.3 kg | 4-20 mA |

Popular Models from Bently Nevada

| Model | Description | Vibration Measurement Range | Weight | Output Signal |

|---|---|---|---|---|

| 330500-03-01-02-00 | Industrial Vibration Sensor | 0.01 to 100 mm/s | 1.5 kg | 4-20 mA |

| 330500-04-01-00-00 | High Precision Vibration Sensor | 0.01 to 10 mm/s | 1.7 kg | 4-20 mA |

| 330106-01-01-00-00 | Vibration Sensor for Turbines | 0.01 to 200 mm/s | 2.0 kg | 4-20 mA |

| 330803-01-00-00-00 | Universal Vibration Sensor | 0.01 to 50 mm/s | 1.8 kg | 4-20 mA |

| 330500-06-02-00-00 | Sensor for Pumps & Compressors | 0.01 to 150 mm/s | 1.9 kg | 4-20 mA |

| 330103-03-12-10-01-00 | Vibration Monitoring System | 0.01 to 50 mm/s | 2.1 kg | 4-20 mA |

Excellent PLC

Excellent PLC