| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

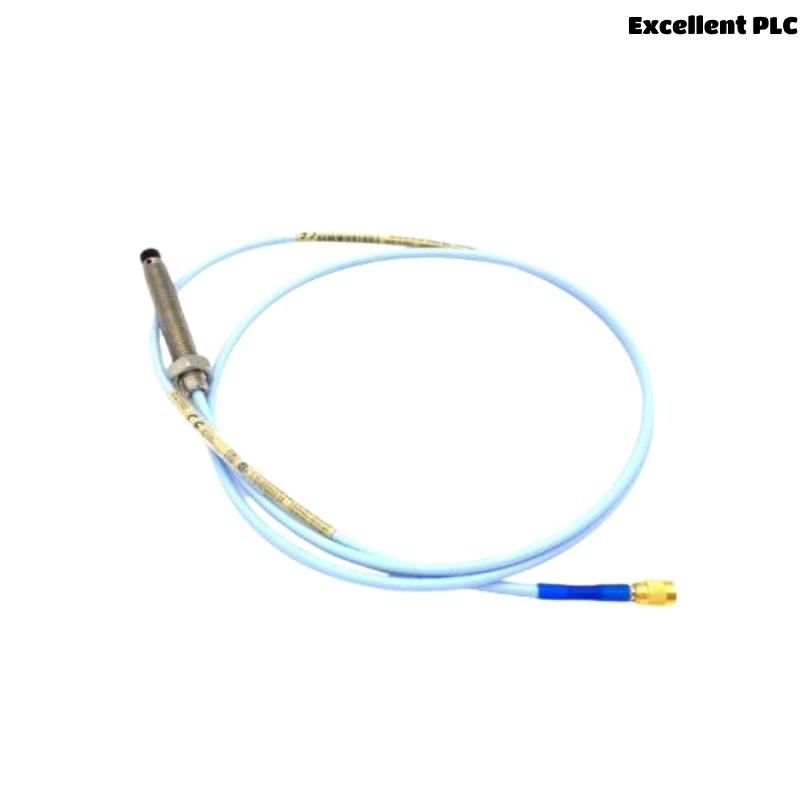

The Bently Nevada 330103-04-13-10-02-00 8 mm Proximity Probe is an integral part of the 3300 XL Series—a line of precision proximity probes specifically designed for high-accuracy displacement and vibration monitoring. The 330103-04-13-10-02-00 model is ideal for use in demanding industrial environments where machinery performance and early detection of faults are critical.

This 8 mm proximity probe leverages eddy current technology to measure the distance between the probe and a target without making contact. This non-invasive measurement method ensures a longer lifespan, greater reliability, and reduced maintenance compared to traditional mechanical sensors. The probe’s durable construction and ability to operate in harsh environments make it a preferred choice for industries such as power generation, oil and gas, manufacturing, and more.

Designed to be used with Bently Nevada’s 3300 XL vibration monitoring system, this probe provides real-time feedback on the condition of critical rotating machinery, including turbines, compressors, pumps, and motors. It helps prevent mechanical failures by enabling proactive maintenance strategies that reduce downtime and repair costs.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330103-04-13-10-02-00 |

| Type | 8 mm Proximity Probe |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Shaft Diameter | 8 mm |

| Operating Temperature | -40°C to +120°C |

| Range | 1-25 mil (0.0254-0.635 mm) |

| Mounting Type | Direct Mount |

| Measurement Principle | Eddy Current |

| Cable Length | 1.0 meter |

| Accuracy | ± 0.001 inch (± 0.0254 mm) |

Product Applications

The 330103-04-13-10-02-00 8 mm proximity probe is used to monitor various types of rotating equipment in industries where uptime is critical and machine failure is costly. Some of its primary applications include:

-

Power Generation: The probe is commonly used to monitor turbines, compressors, and generators in power plants, providing real-time data to prevent damage caused by misalignment, imbalance, or excessive vibration.

-

Oil & Gas Industry: Offshore rigs, refineries, and pipelines rely on this probe to monitor machinery like pumps, motors, and compressors to avoid unplanned shutdowns and improve operational efficiency.

-

Aerospace: In aerospace applications, the 330103-04-13-10-02-00 probe is used to monitor turbines, engines, and other critical components, ensuring high precision in performance and safety.

-

Manufacturing: The probe is ideal for monitoring manufacturing machinery, such as conveyor belts, robotic arms, and motors, where early detection of faults is essential to avoid production halts.

-

Marine Industry: The probe is used in ships and offshore platforms to ensure the continuous operation of engines and other rotating systems, increasing the overall safety of operations.

-

Transportation: In industries such as railways and aviation, the probe is used for continuous monitoring of engine performance, preventing costly breakdowns and improving the lifespan of vital equipment.

Product Advantages

-

High Precision: With an accuracy of ± 0.001 inch (± 0.0254 mm), the 330103-04-13-10-02-00 probe ensures the precise measurement of displacement and vibration, which is essential for accurate diagnostics and predictive maintenance.

-

Rugged Design: The probe can operate in harsh industrial environments with temperatures ranging from -40°C to +120°C, making it suitable for a wide variety of applications in challenging conditions.

-

Non-contact Measurement: The probe uses eddy current technology, which means it can take measurements without touching the machinery, reducing wear and extending the probe’s lifespan.

-

Real-time Data: The 330103-04-13-10-02-00 probe offers continuous monitoring of machinery, providing real-time feedback and early detection of issues such as misalignment, imbalance, and wear.

-

Versatility: With its 8 mm shaft diameter, this probe is highly versatile and can be used on a wide range of machinery, including large turbines and smaller motors, in various industrial settings.

-

Cost Savings: The probe helps prevent equipment failures by providing early warnings of mechanical issues, leading to significant savings in repair costs and minimizing the risk of unplanned downtime.

-

Easy Integration: It seamlessly integrates with Bently Nevada’s 3300 XL system, ensuring smooth communication with other vibration monitoring equipment for a comprehensive monitoring solution.

-

Predictive Maintenance: The probe helps support predictive maintenance programs, enabling operators to take corrective actions before problems escalate, ultimately reducing operational interruptions.

-

Low Maintenance: Due to the non-contact nature of the probe, there’s less wear and tear, requiring less frequent maintenance or replacement, which helps keep operational costs low.

-

Long Operational Life: Designed for long-term reliability, the probe offers extended service life in challenging environments, minimizing the need for frequent replacements.

Frequently Asked Questions (FAQ)

Q1: What type of technology does the 330103-04-13-10-02-00 probe use?

A1: The probe uses eddy current technology to measure displacement and vibration without physical contact, offering high precision and reducing wear.

Q2: What is the accuracy of the 330103-04-13-10-02-00 probe?

A2: The probe offers an accuracy of ± 0.001 inch (± 0.0254 mm), which ensures precise measurements and reliable data for condition monitoring.

Q3: What is the total length of the 330103-04-13-10-02-00 probe?

A3: The total length of the probe is 1.0 meter, providing flexibility for installation in various machinery setups.

Q4: How much does the 330103-04-13-10-02-00 probe weigh?

A4: The probe weighs 0.323 kg, making it easy to handle during installation and maintenance.

Q5: What is the operating temperature range of the probe?

A5: The probe can operate in temperatures ranging from -40°C to +120°C, allowing it to function in a wide range of environments.

Q6: How does this probe support predictive maintenance?

A6: The probe continuously monitors machinery and provides early detection of potential issues, enabling predictive maintenance and reducing the likelihood of costly breakdowns.

Q7: In which industries is the 330103-04-13-10-02-00 probe used?

A7: It is used in industries such as power generation, oil & gas, aerospace, manufacturing, marine, and transportation for monitoring rotating equipment.

Q8: What is the benefit of non-contact measurement?

A8: Non-contact measurement reduces wear on the probe and the machinery, ensuring that both the sensor and the monitored equipment remain in good condition over time.

Q9: Can the 330103-04-13-10-02-00 probe be used for all types of rotating equipment?

A9: Yes, the probe can be used on a wide variety of rotating machinery, including turbines, compressors, pumps, motors, and more.

Q10: How does the probe help detect mechanical problems early?

A10: By continuously measuring displacement and vibration, the probe can detect changes that may indicate mechanical problems such as misalignment or imbalance, allowing for early intervention.

Recommended Related Models (Same Series or Related)

| Model | Description | Range | Accuracy | Mounting |

|---|---|---|---|---|

| 330103-04-13-10-02-01 | Extended range 8 mm proximity probe | 1-50 mil (0.0254-1.27 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-04-13-10-02-02 | High temperature 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-04-13-10-02-03 | 8 mm proximity probe with extended cable | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-04-13-10-02-04 | Hazardous area 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-04-13-10-02-05 | 8 mm proximity probe with custom length | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-04-13-10-02-06 | 8 mm proximity probe for aerospace applications | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

Recommended Popular Models from Bently Nevada

| Model Number | Parameters | Application | Advantages |

|---|---|---|---|

| 330103-00-08-10-01-00 | 24V, 10A, 1-wire | Vibration Monitoring | High accuracy, reliable performance |

| 330103-00-08-10-02-00 | 24V, 12A, 2-wire | Industrial Control Systems | Durable, flexible, high efficiency |

| 330103-00-08-10-03-00 | 24V, 15A, 3-wire | Process Control | High power output, stable operation |

| 330103-00-08-10-04-00 | 24V, 18A, 1-wire | Motor Control Systems | Robust design, efficient performance |

| 330103-00-08-10-05-00 | 24V, 20A, 2-wire | Power Distribution Systems | Reliable, long-lasting, cost-effective |

| 330103-00-08-10-06-00 | 24V, 25A, 3-wire | Automation Systems | High efficiency, versatile integration |

Excellent PLC

Excellent PLC