| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

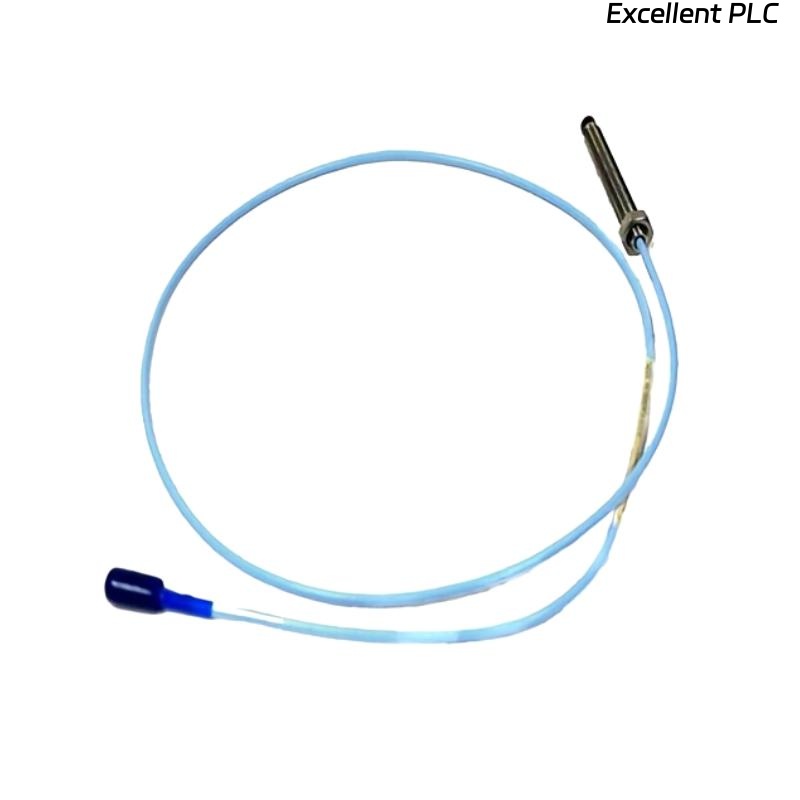

The Bently Nevada 330103-05-12-10-02-00 3300 XL 8mm Proximity Probe is a high-performance non-contact vibration and displacement measurement probe, designed for continuous monitoring of critical rotating machinery. It belongs to the trusted 3300 XL 8mm series, known for precision, reliability, and stability even in challenging industrial environments. This probe uses eddy current measurement technology, enabling it to detect shaft vibration, position, and clearance with high accuracy. Its robust construction ensures durability under mechanical stress, temperature variations, and electromagnetic interference, making it suitable for long-term use in industrial monitoring systems.

Product Parameters

| Parameter | Value |

|---|---|

| Model Number | 330103-05-12-10-02-00 |

| Series | 3300 XL 8mm Proximity Probes |

| Measurement Range | 2 mm (80 mils) linear range |

| Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | 0 to 10 kHz |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 meter |

| Thread Size | M10 × 1 |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -50°C to +200°C |

| Humidity Range | 0–95% non-condensing |

| Insulation Resistance | > 500 MΩ |

| Compatible Extension Cables | 330130 series |

| Compatible Proximitor® | 3300 XL series |

| Weight | 0.323 kg |

| Mounting Option | Threaded mounting with locknut |

Product Applications

The 330103-05-12-10-02-00 probe is designed for critical monitoring applications across industries.

-

Turbomachinery: Continuous measurement of shaft vibration and displacement in turbines, compressors, and pumps.

-

Power Generation: Used in steam and gas turbines for predictive maintenance and early fault detection.

-

Oil & Gas Industry: Essential for compressor and pump monitoring in refineries and offshore rigs.

-

Industrial Manufacturing: Protects high-value equipment such as motors, fans, and gearboxes by providing real-time vibration data.

-

Aerospace and Defense: Suitable for advanced rotating machinery where precision monitoring is crucial.

Product Advantages

-

High Accuracy: Provides precise vibration and displacement measurement with industry-standard sensitivity.

-

Rugged Construction: Withstands harsh conditions including high temperatures and vibrations.

-

Reliable Compatibility: Fully compatible with Bently Nevada 3300 XL Proximitor® sensors and extension cables.

-

Global Standard: Widely adopted across industries as the standard for shaft vibration monitoring.

-

Reduced Downtime: Enables early fault detection, minimizing unexpected failures and operational costs.

-

Ease of Installation: Compact threaded design allows quick mounting and secure fitment.

FAQ

-

What type of measurement technology does the 330103-05-12-10-02-00 probe use?

It uses eddy current technology to detect shaft displacement and vibration without physical contact, ensuring accuracy and long-term stability. -

Is this probe compatible with other Bently Nevada Proximitor® modules?

Yes, it is designed to work seamlessly with the 3300 XL Proximitor® sensors and is backward compatible with many systems in the 3300 series. -

What is the typical sensitivity of this probe?

The standard sensitivity is 7.87 V/mm (200 mV/mil), which ensures precise displacement readings. -

How does the probe handle electromagnetic interference?

The probe is engineered with excellent shielding to resist EMI, ensuring stable and reliable measurements in industrial environments. -

Can the probe be used in high-temperature applications?

Yes, it supports continuous operation at temperatures from -35°C to +180°C, with storage capability up to +200°C. -

Does the probe require calibration?

Factory calibration is provided, and it maintains calibration throughout its life cycle when paired with the correct extension cable and Proximitor®. -

What is the linear measurement range of the probe?

It has a linear range of 2 mm (80 mils), which is standard for 8mm Bently Nevada probes. -

How is the probe typically installed?

It uses a threaded mounting system with a locknut, making installation straightforward and secure in machinery housings. -

Is it suitable for long-term continuous monitoring?

Yes, the probe is specifically designed for continuous operation in critical machinery monitoring systems. -

Can it be integrated into existing vibration monitoring systems?

Absolutely, it integrates easily into Bently Nevada monitoring platforms and other compatible vibration analysis systems.

Recommended Related Models (Same Series)

| Model Number | Description | Total Length | Weight |

|---|---|---|---|

| 330103-02-10-05-02-05-CN | 3300 XL 8mm Proximity Probe | 0.5 m | 0.162 kg |

| 330103-02-12-10-12-05 | 3300 XL 8mm Proximity Probe | 1 m | 0.323 kg |

| 330103-03-07-10-01-00 | 3300 XL 8mm Proximity Probe | 1 m | 0.323 kg |

| 330103-03-10-10-11-00 | 3300 XL 8mm Proximity Probe | 1 m | 0.323 kg |

| 330103-03-10-15-01-05 | 3300 XL 8mm Proximity Probe | 1.5 m | 0.485 kg |

| 330103-05-10-10-12-RU | 3300 XL 8mm Proximity Probe | 1 m | 0.323 kg |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Description | Key Feature |

|---|---|---|

| 330104-00-09-10-02-00 | 3300 XL 11mm Proximity Probe | Extended linear range for larger shaft diameters |

| 330130-040-00 | Extension Cable | Compatible with 3300 XL probes |

| 330180-50-00 | Proximitor® Sensor | Converts probe signal for monitoring systems |

| 3500/22M | Transient Data Interface | High-speed data acquisition for machinery analysis |

| 3500/42M | Proximitor®/Seismic Monitor | Multi-channel vibration monitoring |

| 3500/94M | VGA Display Module | Provides local machine condition display |

Excellent PLC

Excellent PLC