| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

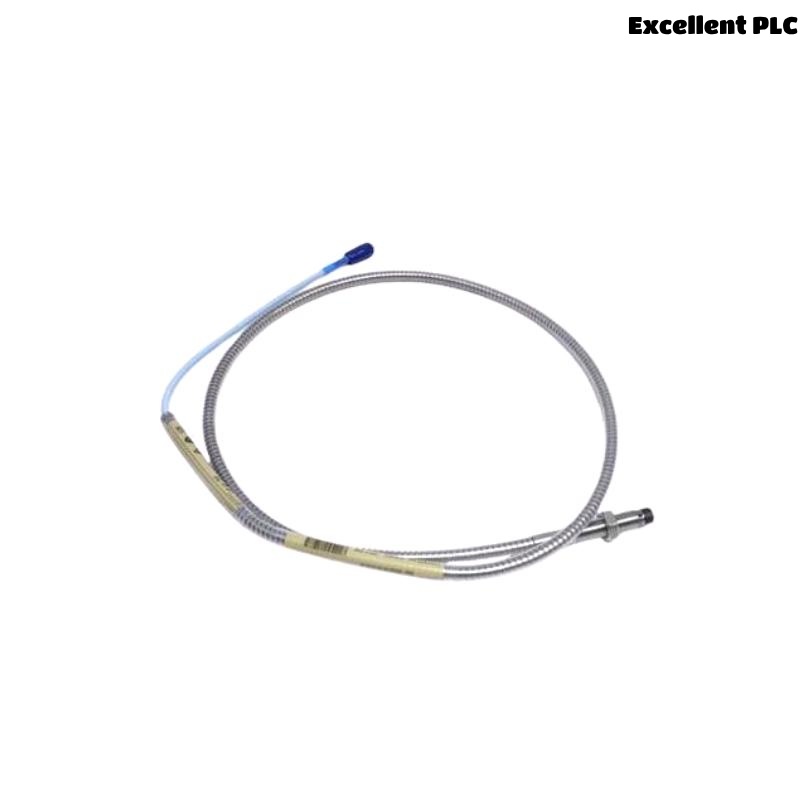

The Bently Nevada 330103-06-15-10-12-CN is part of the 3300 XL series, offering a highly accurate 8mm proximity probe that is designed for precise vibration and displacement measurements in rotating machinery. This probe is particularly suitable for industries where reliable condition monitoring is critical, such as in power generation, aerospace, oil & gas, and manufacturing sectors.

The 3300 XL series is known for its high precision and durability, ensuring that the probe can function effectively even in extreme operating conditions. The 330103-06-15-10-12-CN is specifically designed to be part of a predictive maintenance program, providing real-time data on the vibration and displacement of critical machinery. By offering reliable monitoring, this proximity probe helps avoid unforeseen downtime, reduce maintenance costs, and prolong the lifespan of machinery.

With a total length of 1.0 meter and a weight of just 0.323 kg, it is compact and easy to install, even in tight spaces. This probe is an essential tool in modern condition-based monitoring programs, ensuring that machines are operating optimally.

Product Specifications:

Below are the detailed specifications for the Bently Nevada 330103-06-15-10-12-CN 3300 XL 8mm Proximity Probe:

| Parameter | Specification |

|---|---|

| Product Model | Bently Nevada 330103-06-15-10-12-CN |

| Probe Type | 3300 XL Proximity Probe |

| Nominal Gap | 8 mm |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Mounting Style | Direct mounting to machine surface |

| Measurement Type | Displacement (vibration) |

| Material | Stainless Steel |

| Sensitivity | High precision |

| Output Type | Analog (typically 4-20 mA) |

| Temperature Range | -40°C to +120°C |

| Shock Resistance | Up to 100 g |

| Vibration Resistance | High |

| Operating Frequency Range | Up to 25 kHz |

| Mounting Hole Diameter | 8 mm |

| Certification | CE Certified |

Product Applications:

The Bently Nevada 330103-06-15-10-12-CN proximity probe is ideal for applications in industries where the condition of rotating machinery must be closely monitored. The probe is used for vibration and displacement measurements, making it suitable for a wide range of industrial machines. Here are some of the key applications:

-

Turbine Monitoring: Ideal for monitoring turbines in power plants, the probe ensures that any misalignment or imbalance is detected early, thus preventing catastrophic failures.

-

Compressor Systems: Used extensively in compressors, the proximity probe detects any shifts in vibration or displacement, ensuring the smooth operation of the compressor and preventing damage from misalignment or wear.

-

Pump Monitoring: The probe is used to monitor the displacement of pumps, helping to identify issues such as rotor misalignment or wear that could lead to pump failure.

-

Power Generation Equipment: It is commonly used in power generation systems for monitoring large rotating equipment, including turbines and generators, ensuring they run efficiently and reliably.

-

Aerospace and Automotive Applications: This probe is also used in the aerospace and automotive industries to monitor critical components in engines, turbines, and other high-performance machinery.

-

Manufacturing Plants: In various industrial settings, the 3300 XL 8mm proximity probe is used to monitor rotating machinery like motors, fans, and conveyors to prevent unplanned downtime.

Product Advantages:

-

High-Precision Measurement: The 3300 XL series is renowned for its high accuracy, allowing for the detection of small displacement and vibration changes, which helps prevent premature machinery failure.

-

Durability and Longevity: Made from high-quality stainless steel, this probe can withstand the harsh conditions found in industrial environments, providing reliable performance over time.

-

Wide Temperature Range: The probe operates effectively across a wide temperature range from -40°C to +120°C, making it suitable for both cold and hot operating environments.

-

Compact Design: With a total length of 1.0 meter and a weight of just 0.323 kg, it is lightweight and compact, allowing it to be easily installed even in confined spaces.

-

Shock Resistance: The probe can withstand up to 100 g of shock, ensuring that it continues to perform accurately in high-vibration environments.

-

Easy Integration: The 3300 XL 8mm probe integrates easily with other Bently Nevada condition monitoring systems, such as the 3300 and 3500 series, providing a comprehensive machinery monitoring solution.

-

Real-Time Monitoring: The continuous data provided by this probe enables operators to monitor machinery health in real-time, which is crucial for taking proactive maintenance actions before failures occur.

-

Predictive Maintenance: This probe enables predictive maintenance programs by providing early warning signals for mechanical issues, thereby reducing downtime and lowering maintenance costs.

-

Cost-Effective: By preventing unexpected breakdowns, this probe helps extend the life of machinery and reduces the costs associated with emergency repairs or replacements.

-

High Sensitivity: The high sensitivity of the 3300 XL allows for the detection of even minor changes in vibration, helping identify faults early in the operational cycle.

Frequently Asked Questions (FAQ):

-

What is the nominal gap of the Bently Nevada 330103-06-15-10-12-CN probe?

-

The nominal gap is 8 mm.

-

-

What is the total length of the probe?

-

The total length of the probe is 1.0 meter.

-

-

How much does the probe weigh?

-

The weight of the probe is 0.323 kg.

-

-

What temperature range does the Bently Nevada 330103-06-15-10-12-CN probe operate in?

-

It operates in temperatures ranging from -40°C to +120°C.

-

-

What material is the Bently Nevada 330103-06-15-10-12-CN probe made of?

-

The probe is made of stainless steel, providing durability and resistance to corrosion.

-

-

What type of output does the Bently Nevada 330103-06-15-10-12-CN provide?

-

The output is analog, typically in the range of 4-20 mA.

-

-

How is the Bently Nevada 330103-06-15-10-12-CN mounted?

-

The probe is mounted directly to the machine surface for precise vibration and displacement measurements.

-

-

Can the probe be used in environments with high vibration?

-

Yes, the probe can withstand up to 100 g of shock, making it suitable for high-vibration environments.

-

-

Is the Bently Nevada 330103-06-15-10-12-CN compatible with other Bently Nevada monitoring systems?

-

Yes, it is compatible with Bently Nevada’s 3300 and 3500 series of machinery monitoring systems.

-

-

What machinery can the Bently Nevada 330103-06-15-10-12-CN monitor?

-

This probe is used for monitoring turbines, pumps, motors, compressors, and other rotating machinery in industrial and power generation applications.

-

Related Models (Same Series or Similar):

| Model | Description |

|---|---|

| 330103-06-15-10-12-00 | 3300 XL 8mm proximity probe with 0.5-meter length |

| 330103-06-15-10-12-01 | 3300 XL 8mm proximity probe with extended cable length (1.5 meters) |

| 330103-06-15-10-12-02 | 3300 XL 8mm proximity probe with custom mounting options |

| 330103-06-15-10-12-03 | 3300 XL 10mm proximity probe for larger gap applications |

| 330103-06-15-10-12-04 | 3300 XL 8mm proximity probe with enhanced sensitivity |

| 330103-06-15-10-12-06 | 3300 XL proximity probe with higher shock resistance for rugged environments |

Popular Models from Bently Nevada:

| Model | Description |

|---|---|

| 330103-05-17-10-02-00 | Enhanced version with higher precision for sensitive applications. |

| 330103-06-10-50-02-00 | High-capacity model supporting larger current ranges and industrial use. |

| 330103-05-18-10-02-00 | Compact version with space-saving design for tight installations. |

| 330103-06-11-50-02-00 | Dual-channel model designed for multi-phase systems with increased accuracy. |

| 330103-05-16-10-02-00 | Basic version with reliable performance for standard current measurements. |

| 330103-06-12-50-02-00 | Features extended range and integrated temperature compensation for stable readings. |

Excellent PLC

Excellent PLC