| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

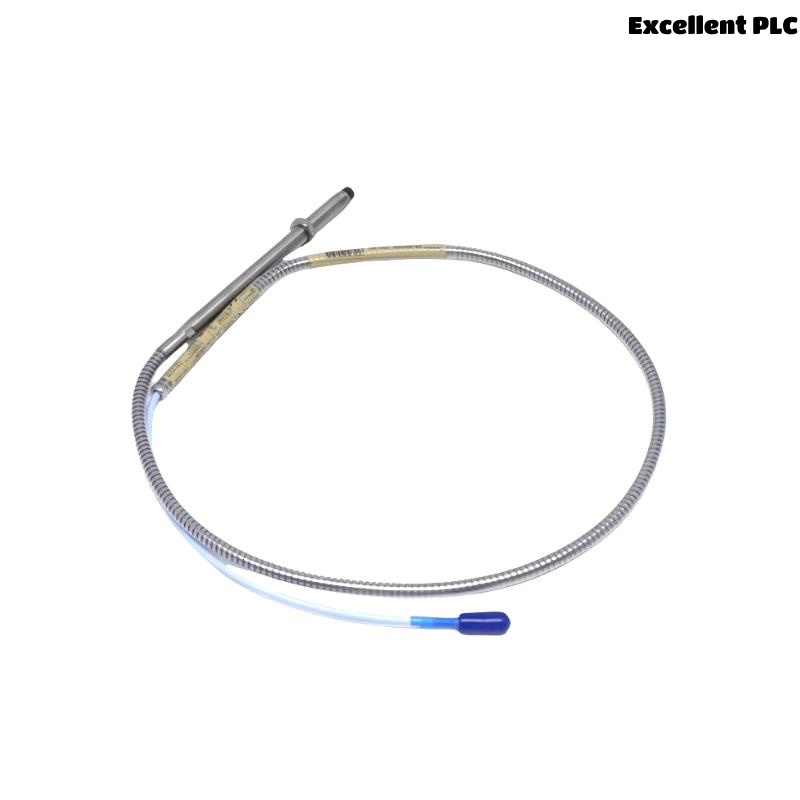

The Bently Nevada 330103-06-25-10-02-00 3300 XL 8mm Proximity Probe is a premium sensor designed for accurate measurement of shaft vibration and position in rotating machinery. As part of Bently Nevada’s globally recognized 3300 XL series, this probe delivers precise, reliable data essential for protecting and optimizing critical assets in power generation, oil & gas, petrochemical, and many other industries.

The 3300 XL 8mm Proximity Probe is built for continuous operation in harsh industrial environments, with rugged stainless steel construction and cable options that withstand a broad temperature range and challenging installation conditions.

Trusted worldwide, this probe helps maximize equipment availability, improve safety, and support predictive maintenance initiatives.

Product Specifications

| Specification | Details |

|---|---|

| Model | 330103-06-25-10-02-00 |

| Series | 3300 XL 8mm Proximity Probes |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Sensing Range | 0 to 2 mm (80 mils) |

| Linear Range | 0.25 mm to 2 mm (10 mils to 80 mils) |

| Non-linearity | ±0.75% of full-scale range |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 meter |

| Thread Type | 3/8-24 UNF |

| Probe Body Material | Stainless Steel |

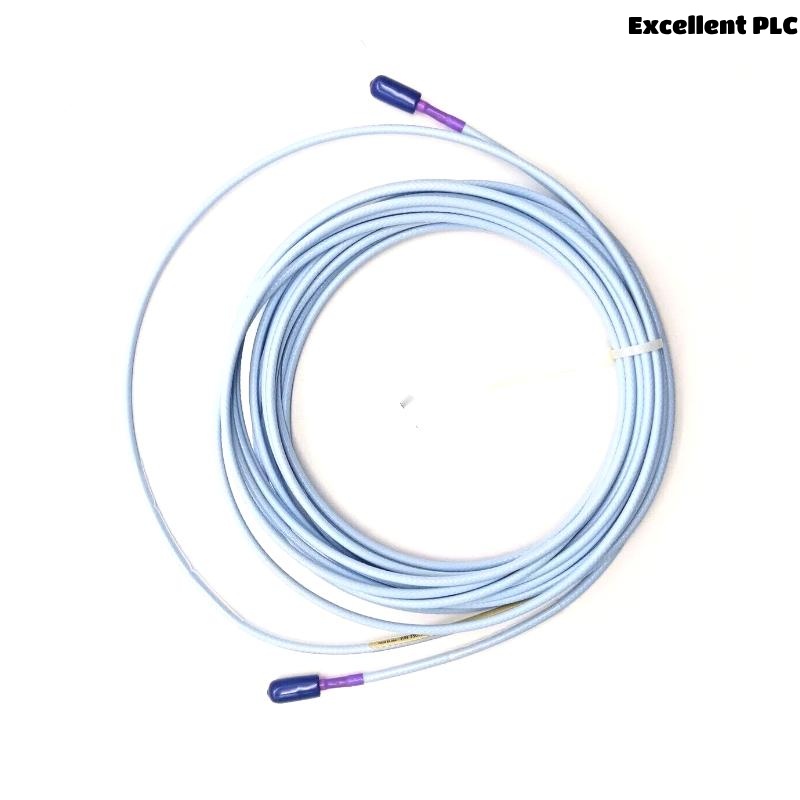

| Cable Jacket Material | Polyethylene (PE), optional FEP |

| Operating Temperature (Probe) | -35°C to +177°C |

| Operating Temperature (Cable) | -51°C to +177°C |

| System Compatibility | Bently Nevada 3300 XL Drivers & Monitors |

| Compliance | API 670 compliant |

| Weight | 0.323 kg |

Applications

The Bently Nevada 330103-06-25-10-02-00 Proximity Probe is used in a wide variety of industries and applications where accurate shaft vibration and position monitoring are critical:

-

Power Generation

Protects turbines, generators, pumps, and critical rotating assets in fossil, nuclear, and hydroelectric plants. -

Oil & Gas

Ensures safe operation of compressors, pumps, and motors in upstream exploration, midstream pipelines, and downstream refining. -

Petrochemical & Chemical

Monitors the condition of rotating equipment in hazardous environments where downtime can be extremely costly. -

Pulp & Paper

Tracks the condition of high-speed rollers, paper machines, and associated rotating equipment. -

Steel & Metals Processing

Monitors vibration in rolling mills, motors, and gearboxes used in heavy industry and manufacturing. -

Marine & Offshore

Applied on ship propulsion systems, generators, and auxiliary rotating equipment for critical condition monitoring.

Advantages

The 330103-06-25-10-02-00 8mm Proximity Probe delivers several key benefits that make it a trusted choice for industry leaders:

-

Industry Proven Performance

Built to deliver stable, accurate performance across millions of installations worldwide. -

API 670 Compliance

Certified to meet or exceed API 670 standards, a requirement for critical equipment monitoring in regulated industries. -

Robust Construction

Stainless steel probe housing and chemically resistant cable options for extreme industrial environments. -

Long System Length

Extension cable supports flexible installations, even on large machines or in remote control rooms. -

High Accuracy and Stability

Exceptional linearity and low drift performance for dependable long-term monitoring. -

Wide Temperature Range

Suitable for extreme hot and cold environments, from offshore platforms to power stations. -

Easy Integration

Fully compatible with Bently Nevada 3300 XL monitoring systems and drivers, ensuring plug-and-play compatibility. -

Minimal Maintenance

Designed for extended service intervals, reducing maintenance costs and supporting predictive maintenance.

FAQs

-

What is the sensing range of the 330103-06-25-10-02-00 probe?

0 to 2 mm (80 mils). -

What is the total system length of this configuration?

1 meter total length. -

Does this probe comply with API 670?

Yes, it is fully API 670 compliant. -

What is the operating temperature range?

Probe: -35°C to +177°C; Cable: -51°C to +177°C. -

Can the cable be used in chemically aggressive environments?

Yes, with optional FEP jacket for harsh chemical environments. -

What is the linear range of measurement?

0.25 mm to 2 mm (10 mils to 80 mils). -

What is the mounting thread?

3/8-24 UNF. -

Is this probe compatible with older Bently Nevada monitoring systems?

It is fully compatible with 3300 XL drivers and monitors. -

What industries typically use this product?

Power generation, oil & gas, petrochemical, paper, metals processing, marine, and more. -

How often does the probe need recalibration?

The probe offers long-term stability with low drift, minimizing recalibration needs.

Related Models

| Model | Description | Key Features |

|---|---|---|

| 330103-05-10-10-12-05 | 8mm Proximity Probe (5 m probe, 12 m cable) | Standard configuration, API 670 compliant |

| 330103-06-13-10-02-00 | 8mm Proximity Probe (6 m probe, 13 m cable) | Long reach installation flexibility |

| 330103-00-10-10-02-05 | 8mm Proximity Probe (10 m cable) | Standard 8mm probe |

| 330104-00-10-10-02-05 | 11mm Proximity Probe | Larger tip, greater sensing range |

| 330105-02-12-10-02-05 | 25mm Proximity Probe | High-clearance large machinery monitoring |

| 330106-05-10-10-02-05 | NSv Narrow Surface Probe | Designed for restricted space installations |

Popular Models from Bently Nevada

| Model | Description | Key Features |

|---|---|---|

| 3300 XL 8mm Proximity Probes | Industry-standard proximity probes | Accurate, API 670 compliant |

| 3300 XL 11mm Proximity Probes | Larger probes for extended range | Greater gap monitoring |

| 3300 XL NSv Proximity Probes | Narrow tip probes | Compact for tight spaces |

| 3500/42M Proximitor Monitor | Advanced monitor for proximity systems | High-performance machinery protection |

| 330400 Velomitor Sensor Series | Velocity sensors for vibration monitoring | High accuracy, easy installation |

| 3500/22M Transient Data Interface | High-speed data capture module | For dynamic transient vibration monitoring |

Excellent PLC

Excellent PLC