| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

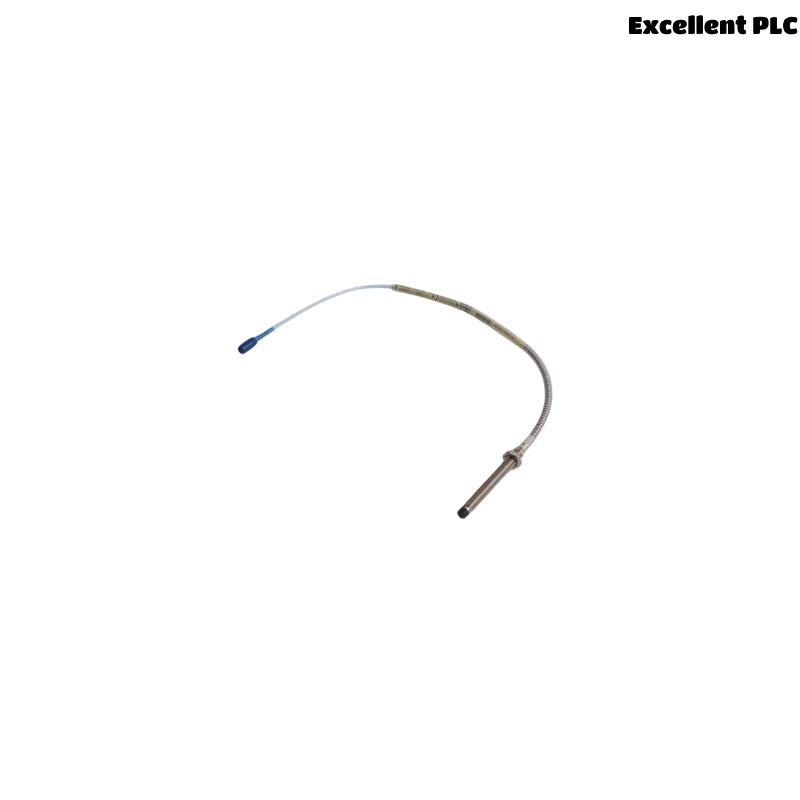

The Bently Nevada 330104‑00‑08‑90‑02‑05 is a 3300 XL 8 mm proximity probe engineered for precision shaft‑displacement measurement in demanding industrial environments. Leveraging eddy‑current, non‑contact sensing, it supplies highly accurate, real‑time data on rotor position, vibration, and dynamic motion. With a total cable length of 9.0 meters and a robust assembly weight of 2.907 kg, this metric probe is designed for installations where the monitoring point is distant from the proximitor or rack input. Its stainless‑steel construction, hermetic sealing, and wide temperature capability allow for dependable operation in turbines, compressors, pumps, and critical rotating machinery found in power generation, oil & gas, refining, and heavy‑process industries.

Beyond raw measurement accuracy, the probe’s mechanical ruggedness and standardized 4‑20 mA interface simplify integration into legacy and modern condition‑monitoring systems. Operators rely on the 3300 XL series to enable condition‑based maintenance, minimize unplanned shutdowns, and extend machinery life.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330104‑00‑08‑90‑02‑05 |

| Probe Tip Diameter | 8 mm |

| Total Length | 9.0 meters |

| Weight | 2.907 kg |

| Sensing Principle | Eddy current (non‑contact) |

| Measurement Range | 0 – 2 mm (typical) |

| Amplitude Linearity | ±1 % full scale |

| Accuracy | ±0.001 mm |

| Output Signal | 4–20 mA proportional |

| Frequency Response | 100 Hz – 5 kHz |

| Operating Temperature | –40 °C to +85 °C |

| Environmental Rating | IP67 (dust / water resistant) |

| Mounting Thread | M10 × 1 (mm), 3/8‑24 adapter available |

| Cable Type | Armored coaxial, FEP jacket |

| Connector | Standard BNC, field‑replaceable |

Product Applications

-

Steam & Gas Turbines – Long‑run cable enables routing through insulated casings and cable trays while maintaining signal integrity for rotor‑thrust and radial‑vibration monitoring.

-

Centrifugal Compressors – Provides continuous displacement data from bearing housings back to remote racks in compressor buildings or control rooms.

-

Large Synchronous Motors & Generators – Monitors shaft position, detecting bow, rubs, or eccentricity over extended cable paths.

-

Pipeline Booster Pumps – Survives wet, corrosive atmospheres; long cable avoids in‑field junction boxes.

-

Refinery Process Fans & Blowers – Tracks shaft movement to prevent mechanical failure under high‑temperature airflow and particulate exposure.

-

Predictive‑Maintenance Programs – Feeds historian and analytics platforms, allowing trend analysis and fault classification for enterprise‑level asset management.

Product Advantages

-

Extended‑Reach Installation – 9 m integrated cable eliminates splices, maintaining signal fidelity across long distances.

-

High‑Resolution Sensing – ±0.001 mm accuracy captures minute positional changes critical for early fault detection.

-

Rugged IP67 Housing – Sealed stainless‑steel body withstands wash‑downs, hydrocarbon mist, and abrasive dust.

-

Wide Temperature Envelope – Consistent metrology from arctic cold to turbine deck heat, reducing probe type inventory.

-

Plug‑and‑Play Compatibility – Matches 3300 XL extension cables, proximitor drivers, and System 1/Orbit 60 monitoring platforms.

-

Non‑Contact Operation – Eliminates mechanical wear, preserves shaft surface integrity, and avoids probe‑induced heat.

-

Stable Frequency Response – 5 kHz bandwidth captures high‑speed transient events such as surge, resonance, or rub.

-

Field‑Replaceable Tip & Connector – Reduces downtime; maintenance crews can service probes without rerunning entire cable lengths.

-

Metric Thread with Adapter Options – Flexible mounting in European or mixed‑standard plants.

-

Proven Lifecycle Economics – Decades‑long service life and minimal calibration drift lower total cost of ownership.

Frequently Asked Questions (FAQ)

-

What does the 330104‑00‑08‑90‑02‑05 measure?

It measures the static and dynamic displacement of rotating shafts relative to their bearing housings. -

Why choose the 9 m cable version?

For machinery where the proximitor or monitoring rack is located far from the sensor location, reducing junction points and signal loss. -

Is the probe compatible with legacy Bently Nevada racks?

Yes. It conforms to 3300 XL probe standards and interfaces with 3300/5, 3500, and Orbit 60 systems. -

What is the minimum bend radius of the armored cable?

25 mm (1 inch) to prevent conductor fatigue. -

How often should the probe be calibrated?

A functional check during major outages (usually every 3–4 years) is recommended; calibration drift is minimal. -

Can the probe handle oil contamination?

Yes. The stainless housing and FEP jacket resist hydrocarbon exposure; IP67 sealing prevents ingress. -

What is the maximum vibration velocity the probe can track?

Within its bandwidth, it reliably tracks vibration velocities up to 200 mm/s. -

Does the probe require a separate ground?

No. The coaxial shield provides reference grounding; ensure grounding at the proximitor end only. -

Can I cut the cable shorter?

No. Cable length is factory‑matched to probe calibration. Order the exact length needed. -

What standards does the probe meet?

Complies with API 670 guidelines for machinery protection systems.

Recommended Related Models (Same Series)

| Model | Description | Total Length | Weight |

|---|---|---|---|

| 330104‑00‑08‑40‑02‑00 | 8 mm XL probe, armored | 4.0 m | 1.292 kg |

| 330104‑00‑08‑20‑02‑05 | 8 mm XL probe, standard | 2.0 m | 0.645 kg |

| 330104‑00‑08‑05‑02‑05 | 8 mm XL probe, compact | 0.5 m | 0.161 kg |

| 330104‑00‑08‑01‑10‑05 | 8 mm XL probe, ultra‑short | 0.1 m | 0.0323 kg |

| 330104‑00‑10‑90‑02‑05 | 10 mm XL probe, long‑reach | 9.0 m | 3.120 kg |

| 330104‑00‑11‑50‑02‑00 | 11 mm reverse‑mount probe | 5.0 m | 1.860 kg |

Other Popular Bently Nevada Models

| Model | Description | Total Length | Weight |

|---|---|---|---|

| 330103‑12‑20‑50‑02‑00 | 3300 XL 8 mm probe, 5 m | 1.615 kg | |

| 330103‑17‑23‑05‑02‑05 | 3300 XL 8 mm probe, 0.5 m | 0.161 kg | |

| 330103‑30‑10‑40‑00‑61‑02‑00 | 3300 XL 8 mm probe, 4 m (armored) | 1.292 kg | |

| 330130‑025‑00‑10 | 3300 XL 8 mm extension cable, 5 m | 0.350 kg | |

| 330180‑91‑00 | 3300 XL Proximitor sensor (DIN rail) | — | 0.500 kg |

| 3500/42M | Proximitor/Seismic Monitor module – 3500 rack | — | 0.700 kg |

Excellent PLC

Excellent PLC