| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

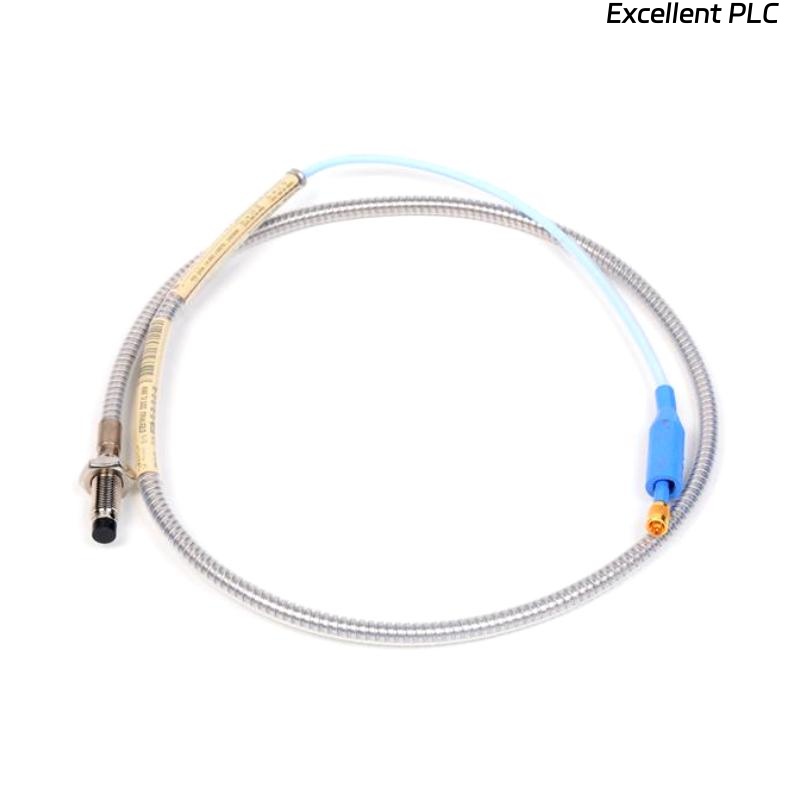

The Bently Nevada 330104-00-02-10-01-00 3300 XL 8 mm Proximity Probe is a precision-engineered sensor designed for vibration and position measurement in critical rotating machinery. As part of the 3300 XL series, this probe provides highly reliable proximity measurement by using eddy current technology to detect shaft displacement relative to the probe tip. It is specifically optimized for use in industrial environments where accuracy, durability, and long-term stability are essential.

Product Advantages

-

High Accuracy: Provides precise shaft displacement and vibration measurements.

-

Reliability in Harsh Environments: Resistant to electrical noise, temperature variations, and contaminants.

-

Part of the 3300 XL System: Fully compatible with 3300 XL Proximitor sensors and extension cables for a complete monitoring chain.

-

Long-Term Stability: Designed for stable performance even during extended operational periods.

-

Flexible Integration: Can be used across a variety of rotating machinery, including turbines, compressors, and pumps.

-

Improved Safety and Maintenance: Enables predictive maintenance and reduces risk of catastrophic equipment failure.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330104-00-02-10-01-00 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Linear Range | 2 mm (80 mils) typical |

| Sensitivity | 200 mV/mil (7.87 mV/µm) |

| Frequency Range | DC to 10 kHz |

| Weight | 0.323 kg |

| Total Length | 1 m |

| Operating Temperature | -35 °C to +177 °C |

| Humidity Tolerance | Up to 95% non-condensing |

| Compatibility | Works with 3300 XL Proximitor Sensor and extension cables |

Product Applications

-

Turbomachinery monitoring: For steam turbines, gas turbines, and hydro turbines.

-

Compressors and pumps: Shaft vibration and axial position monitoring.

-

Gearboxes: Condition monitoring for wear and misalignment.

-

Motors and generators: Ensuring reliability and preventing unexpected shutdowns.

-

Power plants: Continuous monitoring in nuclear, hydro, and thermal plants.

-

Oil & gas industry: Machinery protection in upstream, midstream, and downstream operations.

FAQ

Q1: How does the 330104-00-02-10-01-00 proximity probe detect shaft displacement?

A1: It uses eddy current technology to sense changes in the electromagnetic field caused by the shaft’s movement, translating these variations into voltage signals.

Q2: Can this probe be used with non-metallic shafts?

A2: No, the probe requires a conductive metallic target surface to generate accurate displacement signals.

Q3: Is the probe affected by electromagnetic interference from nearby equipment?

A3: The 3300 XL series is designed with noise immunity features, making it highly resistant to EMI in industrial environments.

Q4: What Proximitor sensors are compatible with this probe?

A4: It is fully compatible with the Bently Nevada 3300 XL Proximitor sensors, ensuring precise calibration and signal accuracy.

Q5: How is the probe typically mounted on machinery?

A5: It is mounted through a threaded probe housing, often positioned to directly face the shaft surface for accurate readings.

Q6: What role does cable length play in probe performance?

A6: Cable length is factory-matched to the Proximitor sensor; incorrect cable length may affect calibration and linearity.

Q7: Can the probe be used in high-temperature environments?

A7: Yes, it is rated for operation up to +177 °C, suitable for demanding turbine and compressor environments.

Q8: Does the probe measure both static and dynamic shaft movement?

A8: Yes, it provides measurements of both static shaft position and dynamic vibration.

Q9: Is the probe suitable for hazardous area installations?

A9: Certain configurations of the 3300 XL system are certified for hazardous environments; users should confirm compliance with site requirements.

Q10: Can the probe signal be integrated into a condition monitoring system?

A10: Yes, it is designed for seamless integration with Bently Nevada monitoring systems, including the 3500 and Orbit platforms.

Related Models

| Model Number | Description |

|---|---|

| 330103-00-07-10-02-00 | 3300 XL 8 mm Proximity Probe, alternative length |

| 330105-02-12-10-02-00 | 3300 XL 11 mm Proximity Probe |

| 330106-05-30-10-02-00 | 3300 XL 25 mm Proximity Probe |

| 330130-040-00-00 | 3300 XL Extension Cable |

| 330180-91-00 | 3300 XL Proximitor Sensor |

| 330104-00-05-10-02-00 | 3300 XL 8 mm Probe, different configuration |

Popular Models from Bently Nevada

| Model Number | Description |

|---|---|

| 3500/22M | Transient Data Interface Module |

| 3500/42M | Proximitor/Seismic Monitor |

| 3500/92 | Communication Gateway Module |

| 330103-00-07-10-02-00 | 3300 XL 8 mm Proximity Probe |

| 330105-02-12-10-02-00 | 3300 XL 11 mm Proximity Probe |

| 330106-05-30-10-02-00 | 3300 XL 25 mm Proximity Probe |

| 330180-91-05 | 3300 XL Proximitor Sensor |

| 330850-90-05 | High-Temperature Accelerometer |

Excellent PLC

Excellent PLC