| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

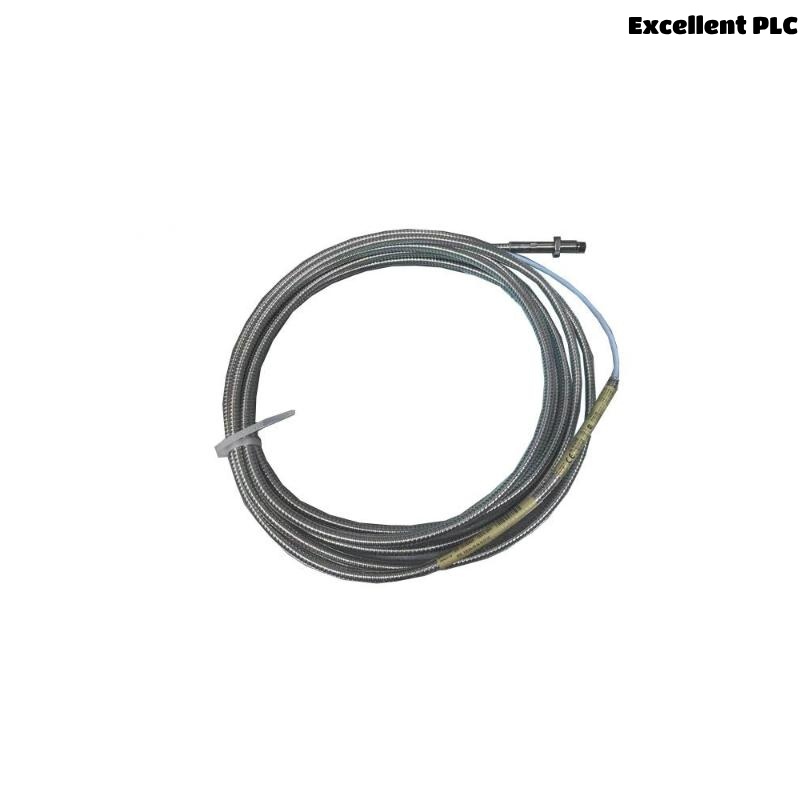

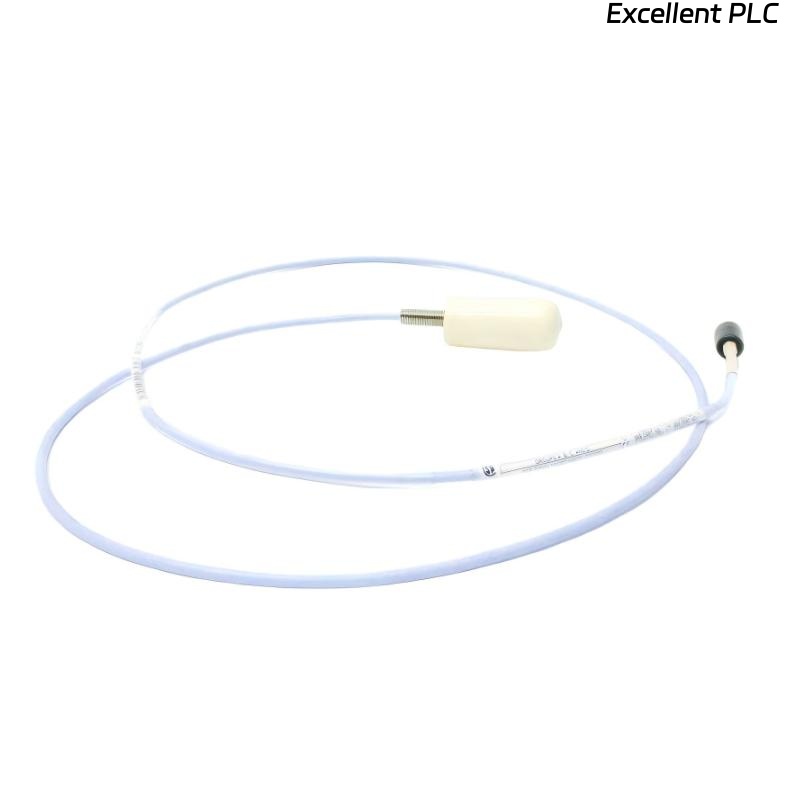

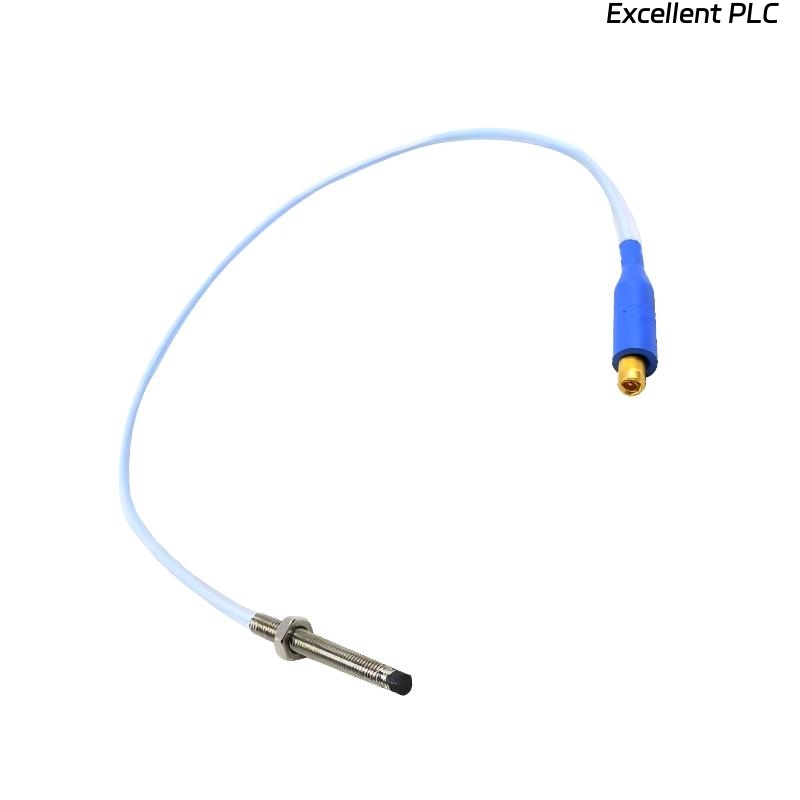

The Bently Nevada 330104-00-05-90-02 3300 XL 8 mm proximity probe is an advanced measurement tool designed to monitor vibration and displacement in rotating machinery. Part of the 3300 XL series, this probe is specifically engineered for high-precision measurements, offering crucial data for maintaining the health of industrial machinery. With its ability to detect even the smallest mechanical imbalances, misalignments, and bearing wear, this probe is an essential component of predictive maintenance programs aimed at improving operational reliability and minimizing downtime.

The 3300 XL series is well-known in the field of machinery condition monitoring and is trusted by industries such as power generation, oil & gas, manufacturing, and chemical processing. This model, with a total length of 9.0 meters and a weight of 2.907 kg, is particularly suitable for larger installations and applications requiring long-range measurements. It delivers highly accurate, real-time data, enabling operators to identify issues early and take appropriate corrective actions before they result in costly repairs or unplanned shutdowns.

Product Parameters

The following table outlines the key technical specifications for the Bently Nevada 330104-00-05-90-02 3300 XL 8 mm proximity probe:

| Parameter | Value |

|---|---|

| Model | 330104-00-05-90-02 |

| Total Length | 9.0 meters |

| Weight | 2.907 kg |

| Sensing Range | 8 mm |

| Measurement Type | Proximity/Vibration Sensor |

| Operating Temperature | -40°C to +85°C |

| Mounting Style | Threaded/Stud Mount |

| Material | Stainless Steel |

| Voltage Rating | 24V DC |

| Output | 4-20 mA |

| Application | Vibration Monitoring, Machinery Health Monitoring |

Product Applications

The Bently Nevada 330104-00-05-90-02 3300 XL 8 mm proximity probe is designed to monitor a wide variety of rotating machinery, ensuring optimal performance and early detection of mechanical issues. The following are key applications for this proximity probe:

-

Turbine Monitoring: In power plants, turbines are critical to energy production, and their health must be continuously monitored. The 3300 XL proximity probe detects imbalances, misalignments, and bearing wear, preventing turbine failures and ensuring reliable performance.

-

Compressor Monitoring: Compressors in industries like oil and gas, petrochemical, and HVAC systems are vital for maintaining operational efficiency. This proximity probe provides real-time measurements of vibration and displacement, helping detect issues before they lead to mechanical failure.

-

Pump Monitoring: Pumps in industries such as water treatment, mining, and oil & gas require constant monitoring for vibrations that could signal wear or misalignment. The 3300 XL 8 mm proximity probe provides early warning of issues, allowing for timely maintenance and preventing costly downtime.

-

Motor Condition Monitoring: Motors in industrial environments need to be regularly checked for signs of degradation. The 3300 XL 8 mm probe helps detect misalignment, imbalance, and bearing failure, ensuring that motors remain in optimal condition and minimizing the risk of failure.

-

General Machinery Monitoring: The 3300 XL 8 mm proximity probe is widely used to monitor other types of rotating machinery such as gearboxes, fans, and conveyors. It enables operators to detect even small faults early, allowing for corrective actions before issues escalate.

This proximity probe is essential for maintaining operational efficiency and preventing unplanned downtime across various industries, ensuring that machinery continues to perform at its best.

Product Advantages

The Bently Nevada 330104-00-05-90-02 3300 XL 8 mm proximity probe offers several advantages that make it a superior choice for monitoring machinery health:

-

Precision Measurement: The 8 mm sensing range allows the probe to detect even the smallest vibrations and positional shifts, making it ideal for precise measurement in rotating machinery.

-

Durability: Made from stainless steel, the probe is built to withstand harsh industrial environments, offering long-term reliability and minimal maintenance.

-

Wide Temperature Range: This probe operates efficiently in a broad temperature range of -40°C to +85°C, ensuring performance in both extremely hot and cold environments.

-

Long Measurement Range: With a total length of 9.0 meters, the probe provides flexibility for installations where longer distances are required, making it ideal for larger machinery or installations with a significant spatial distance between the probe and the measurement point.

-

Standard Output: The 4-20 mA output signal ensures compatibility with most industrial control systems, allowing seamless integration into existing machinery monitoring setups.

-

Easy Installation: The threaded/stud mount design simplifies the installation process, ensuring that the probe is securely and correctly positioned on the machinery without complicated setup procedures.

-

Proactive Monitoring: By providing real-time data, the probe enables proactive monitoring and maintenance, which helps to detect potential issues before they escalate into costly breakdowns or equipment failures.

-

Cost-Effective Solution: The early fault detection capabilities of the probe help to minimize unplanned downtime and expensive repairs, providing a cost-effective solution for machinery health management.

Frequently Asked Questions (FAQ)

-

What does the Bently Nevada 3300 XL 8 mm proximity probe measure?

-

The probe measures the displacement and vibration of rotating machinery components, allowing for early detection of mechanical issues like misalignment, imbalance, and bearing wear.

-

-

What is the total length of the 3300 XL 8 mm proximity probe?

-

The probe has a total length of 9.0 meters, which allows it to be used in applications where longer distances between the machinery and the measurement point are required.

-

-

How much does the Bently Nevada 3300 XL 8 mm proximity probe weigh?

-

The probe weighs 2.907 kg, making it suitable for installations where a heavier probe is required for long-distance monitoring.

-

-

What is the operating temperature range for this proximity probe?

-

The probe operates within a temperature range of -40°C to +85°C, ensuring it performs well in both very cold and high-temperature environments.

-

-

How is the Bently Nevada 3300 XL 8 mm proximity probe mounted?

-

The probe is mounted using a threaded/stud mount, ensuring secure and stable installation on rotating machinery components.

-

-

What output does the 3300 XL 8 mm proximity probe provide?

-

The probe provides a 4-20 mA output, which is standard for many industrial monitoring systems, making it compatible with existing setups.

-

-

In which industries can the 3300 XL 8 mm proximity probe be used?

-

The probe is used in industries like power generation, oil and gas, manufacturing, and water treatment, where machinery health monitoring is critical.

-

-

Can the 3300 XL 8 mm proximity probe detect small mechanical faults?

-

Yes, the probe’s 8 mm sensing range allows it to detect even minor shifts or vibrations, helping to identify mechanical issues early before they become major problems.

-

-

How does this proximity probe help reduce downtime?

-

By providing continuous, real-time data, the probe allows for early detection of faults, enabling proactive maintenance and reducing the likelihood of unexpected breakdowns.

-

-

What makes the 3300 XL 8 mm proximity probe suitable for large-scale installations?

-

The probe’s 9.0 meter length provides flexibility for larger installations, making it ideal for applications where measurement points are spread over long distances.

-

Related Models from the 3300 XL Series

| Model | Description |

|---|---|

| 330104-00-13-15-01-00 | High-performance control unit for industrial process automation |

| 330104-00-05-05-01-CN | Specialized control system designed for Chinese industrial sectors |

| 330104-00-13-15-01-01 | Modular system for energy-efficient manufacturing operations |

| 330104-00-05-05-01-CN1 | Robust unit for real-time monitoring and control in production |

| 330104-00-13-15-01-02 | Advanced unit for optimized process control in automated environments |

| 330104-00-05-05-01-CN2 | Flexible module for large-scale automated systems in critical industries |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330104-00-08-05-01-05 | Advanced control module for real-time industrial automation |

| 330104-00-08-50-01-05 | High-performance controller for energy management systems |

| 330104-00-08-05-01-06 | Modular system for process control and optimization in factories |

| 330104-00-08-50-01-06 | Flexible control unit for precision operations in manufacturing |

| 330104-00-08-05-01-07 | Specialized module for automated systems in critical infrastructure |

| 330104-00-08-50-01-07 | Robust unit for large-scale industrial operations and monitoring |

Excellent PLC

Excellent PLC