| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

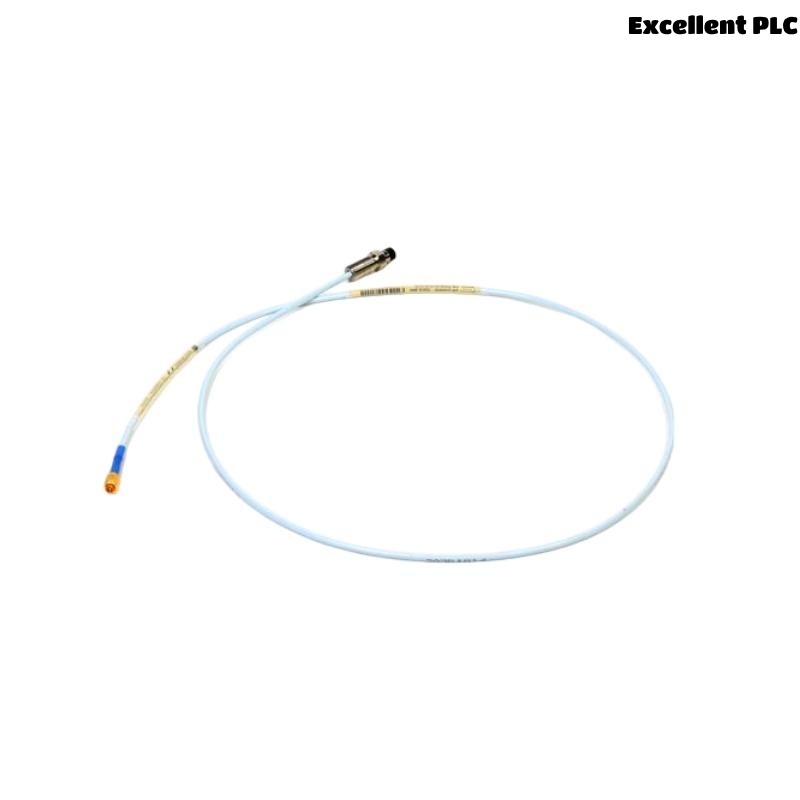

The Bently Nevada 330104-00-07-10-12-00 is a high-performance proximity probe from the 3300 XL 8 mm series, designed specifically for precise non-contact vibration and position measurements in rotating machinery. Engineered with Bently Nevada’s proprietary technology, it delivers consistent performance in demanding industrial environments such as turbines, compressors, pumps, and gearboxes.

This metric version of the probe features an 8 mm tip and is optimized for shaft diameters and installation requirements aligned with ISO standards. The model ensures full compatibility with Bently Nevada’s 3300 XL Proximitor sensors and extension cables, providing accurate displacement measurements and reliable condition monitoring for critical assets.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330104-00-07-10-12-00 |

| Series | 3300 XL 8 mm |

| Sensing Technology | Eddy Current |

| Tip Diameter | 8 mm |

| Probe Case Material | AISI 304 Stainless Steel |

| Connector Type | Male Coaxial Connector |

| Cable Length | 1.0 meter |

| Connector Location | Straight |

| Thread Size | M10 x 1.0 |

| Mounting Length | 71 mm |

| Total Length | 1.0 meter |

| Temperature Range | -35°C to +177°C |

| Weight | 0.323 kg |

| Environmental Protection | IP68 |

| System Compatibility | 3300 XL Extension Cable & Proximitor Sensor |

Applications

The 330104-00-07-10-12-00 proximity probe is widely used across multiple industries for machinery condition monitoring and protection. Typical application areas include:

-

Gas and Steam Turbines: Shaft vibration and thrust position measurement

-

Compressors and Pumps: Bearing health monitoring and dynamic analysis

-

Motors and Generators: Detects misalignment, unbalance, and looseness

-

Gearboxes: Backlash and gear wear detection

-

Hydro Turbines: Shaft runout monitoring

This probe is a fundamental part of a complete machinery protection system, providing precise feedback to prevent unexpected failures and optimize predictive maintenance strategies.

Product Advantages

-

High Reliability in Harsh Environments: Rugged stainless steel construction and IP68 rating provide superior resistance to moisture, dust, and oil.

-

Long-Term Stability: Backed by over 40 years of eddy current expertise from Bently Nevada, ensuring accurate performance over the probe’s life.

-

Easy Integration: Designed to work seamlessly with 3300 XL Proximitor sensors and extension cables, reducing installation time.

-

Global Compliance: Fully meets API 670 and ISO standards, making it suitable for use in safety-critical industrial systems.

-

Enhanced Performance: Offers precise linearity over a wide dynamic range with minimal temperature drift.

-

Flexible Configuration: Various thread lengths, cable types, and connector orientations available for complex installation scenarios.

Frequently Asked Questions (FAQ)

Q1: What does the “1.0 meter” length refer to?

A1: It refers to the total length of the probe’s integral cable, which connects the probe to the extension cable.

Q2: Can this probe be used with a different proximitor sensor series?

A2: It is recommended to use this probe only with the 3300 XL series Proximitor sensors for optimal calibration and performance.

Q3: What is the operating temperature range for this probe?

A3: The probe operates reliably between -35°C and +177°C.

Q4: Is the 330104-00-07-10-12-00 probe suitable for underwater applications?

A4: Yes, the probe has an IP68 rating, allowing for submerged operation under specified conditions.

Q5: How does this model differ from the imperial version?

A5: This is the metric version, designed with metric thread sizes and installation lengths; the imperial version uses inches.

Q6: Can I install this probe near magnetic interference?

A6: Avoid installing it near strong magnetic fields as it may impact the eddy current sensing accuracy.

Q7: What happens if I use a non-Bently Nevada extension cable?

A7: Using third-party cables can compromise signal integrity and system performance. Always use Bently Nevada cables.

Q8: How is the alignment verified during installation?

A8: A dial indicator or a mechanical depth gauge is typically used to ensure proper target distance (gap).

Q9: Does the probe require calibration after installation?

A9: No user calibration is needed; however, system verification using Bently Nevada tools is recommended.

Q10: What maintenance is required for this proximity probe?

A10: It is maintenance-free, but periodic inspection and cleaning of the tip are advised in contaminated environments.

Recommended Related Models (Same Series)

| Model | Description | Dimensions | Weight |

|---|---|---|---|

| 330104-00-08-90-02-05 | 8 mm probe, 8.0 m cable, 90° connector | 8 mm tip, M10 thread | 0.310 kg |

| 330104-00-10-10-02-00 | 8 mm probe, 10.0 m cable, straight | 8 mm tip, M10 thread | 0.325 kg |

| 330104-00-05-10-12-00 | 8 mm probe, 5.0 m cable, straight | 8 mm tip, M10 thread | 0.310 kg |

| 330104-00-07-10-10-00 | 8 mm probe, 7.0 m cable, straight | 8 mm tip, M10 thread | 0.318 kg |

| 330104-00-12-10-02-00 | 8 mm probe, 12.0 m cable, straight | 8 mm tip, M10 thread | 0.330 kg |

| 330104-00-06-10-12-00 | 8 mm probe, 6.0 m cable, straight | 8 mm tip, M10 thread | 0.312 kg |

Recommended Popular Bently Nevada Models

| Model | Description | Dimensions | Weight |

|---|---|---|---|

| 330130-040-00-00 | Extension Cable, 4.0 m, XL Series | Coaxial, Shielded | 0.280 kg |

| 330180-91-00 | Proximitor Sensor, 3300 XL, DIN mount | 71 mm x 25 mm x 25 mm | 0.450 kg |

| 330500-02-00 | Velocity Sensor, Accelerometer-Based | 2-pin connector, top exit | 0.360 kg |

| 991-06-50-01-01 | Keyphasor Module, Dual Channel | 6 mm x 50 mm shaft | 0.390 kg |

| 330106-05-30-10-02-00 | 5 mm proximity probe, 3.0 m cable | 5 mm tip, M8 thread | 0.285 kg |

| 330101-00-05-10-02-00 | 3300 XL 8 mm probe, 5.0 m cable, imperial | 8 mm tip, 3/8-24 UNF thread | 0.312 kg |

Excellent PLC

Excellent PLC