| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

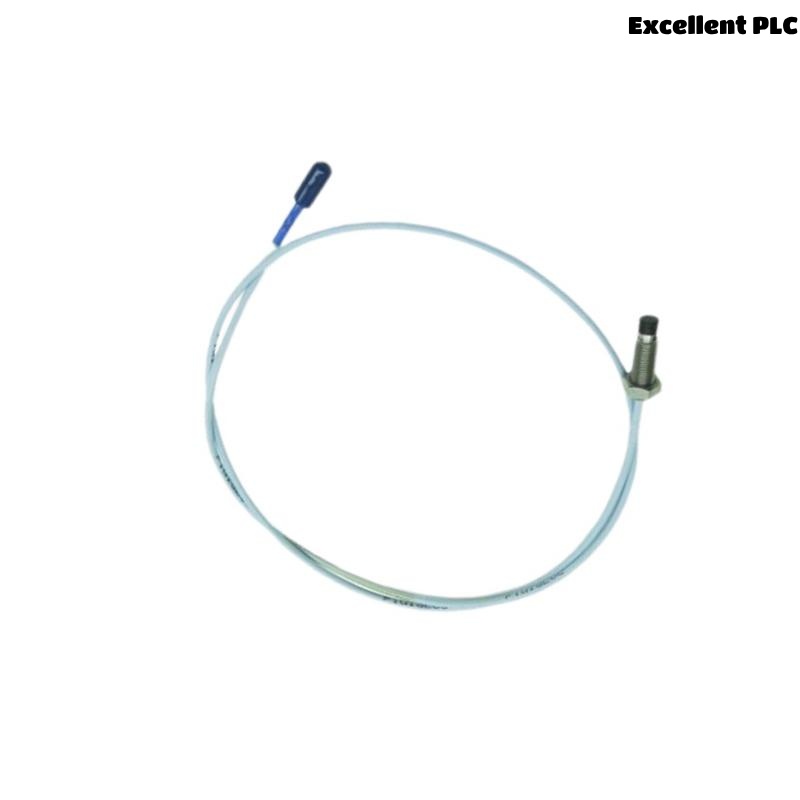

The Bently Nevada 330104-00-08-10-02-00 is a precision-engineered 8 mm proximity probe designed for industrial machinery condition monitoring. Utilizing eddy current sensing technology, this probe delivers accurate and reliable measurements of shaft vibration and displacement in rotating equipment. With a total length of 1.0 meter and a lightweight construction of 0.323 kg, it combines durability with ease of installation.

The probe features a metric connector and a rugged stainless steel tip, which ensures longevity even in demanding environments such as power plants, refineries, and heavy industrial machinery. This product is part of the trusted 3300 XL family, known globally for its ability to help prevent unexpected machinery failures by providing early warning signs of mechanical issues.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330104-00-08-10-02-00 |

| Probe Tip Diameter | 8 mm |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Sensing Technology | Eddy Current |

| Measurement Range | Up to 1.27 mm (50 mils) typical |

| Operating Temperature | -40°C to +120°C |

| Mounting Type | Threaded Mount |

| Connector Type | Metric |

| Probe Material | Stainless Steel |

| Vibration Resistance | High |

| Shielding | Yes |

Product Applications

The 330104-00-08-10-02-00 proximity probe is commonly applied in the monitoring of critical rotating machinery. Its key applications include:

-

Gas and steam turbines: for detecting shaft displacement and vibration to avoid catastrophic failures

-

Compressors: used in petrochemical and oil & gas sectors to monitor shaft conditions

-

Pumps: employed in chemical plants and water treatment facilities to ensure smooth operations

-

Electric motors and generators: for maintaining performance and preventing unexpected shutdowns

-

Gearboxes and drives: to detect misalignments or wear before mechanical failure occurs

-

Marine propulsion systems: withstanding harsh marine environments for continuous condition monitoring

This probe is essential in industries where reliability and safety are paramount, offering an early indication of wear, imbalance, or misalignment in rotating machinery.

Product Advantages

-

Provides non-contact, wear-free measurement, extending the service life of both probe and equipment.

-

Designed with a metric connector for global compatibility and ease of integration.

-

Rugged stainless steel tip offers excellent resistance to corrosion and mechanical damage.

-

Equipped with shielded cable to reduce electrical noise and maintain signal accuracy.

-

Operates effectively across a wide temperature range, suitable for various industrial environments.

-

Threaded mounting ensures secure and straightforward installation.

-

The probe is lightweight (0.323 kg), minimizing any additional mechanical load on monitored equipment.

-

Delivers accurate displacement measurements critical for predictive maintenance strategies.

-

Trusted by industries worldwide for its reliability and durability under demanding conditions.

-

Supports continuous condition monitoring, helping avoid costly unscheduled downtime and maintenance.

Frequently Asked Questions (FAQ)

-

What machinery is compatible with the Bently Nevada 330104-00-08-10-02-00 probe?

It is suitable for use with turbines, compressors, pumps, motors, and other rotating machinery. -

What is the probe’s total length?

The probe has a total length of 1.0 meter. -

What is the weight of this proximity probe?

The probe weighs 0.323 kg. -

What sensing technology does the probe use?

It uses eddy current technology for non-contact displacement measurement. -

Can the probe be used in high-temperature environments?

Yes, it operates reliably within the range of -40°C to +120°C. -

What type of connector does this probe have?

The probe is equipped with a metric connector. -

How is the probe mounted on machinery?

It uses threaded mounting for secure and easy installation. -

Is the probe resistant to vibration and mechanical stress?

Yes, it is designed to withstand high vibration and harsh industrial conditions. -

Can this probe be used in marine or offshore applications?

Yes, the stainless steel construction and design make it suitable for marine environments. -

What maintenance is required for the Bently Nevada 330104-00-08-10-02-00 probe?

Regular inspection during scheduled maintenance is recommended to ensure optimal performance.

Recommended Related Models

| Model Number | Description |

|---|---|

| 330104-00-07-10-02-00 | 8 mm Proximity Probe (metric, standard connector) |

| 330110-00-07-10-02-00 | High Temperature 8 mm Proximity Probe |

| 330106-00-07-10-02-00 | 5 mm Proximity Probe (metric) |

| 330180-91-05 | Reverse Mount Proximity Probe |

| 330130-00-07-10-02-00 | Ruggedized 8 mm Proximity Probe |

| 330105-00-07-10-02-00 | 8 mm Proximity Probe for harsh environments |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/05-03-02-00 | System Rack for 3500 Monitoring Systems |

| 3500/22-01-01-00 | Transient Data Interface Module |

| 3500/40M-01-00 | Proximitor Monitor |

| 3500/42M-01-00 | Vibration Monitor |

| 330103-00-05-10-02-00 | High Temperature 8 mm Proximity Probe |

| 330106-05-30-10-02-00 | 5 mm Proximity Probe, Panel Mount |

Excellent PLC

Excellent PLC