| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Description

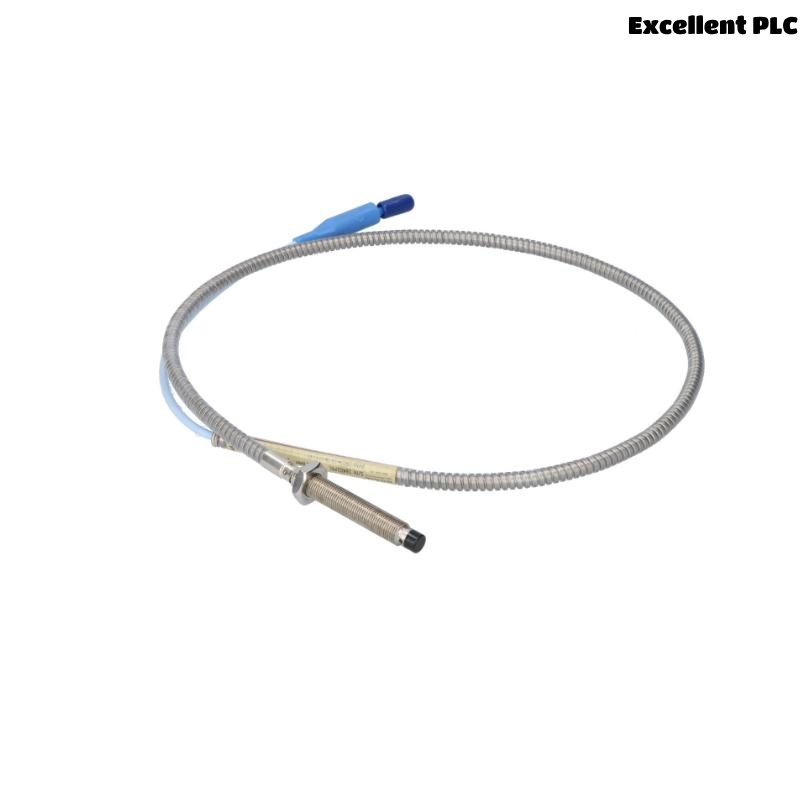

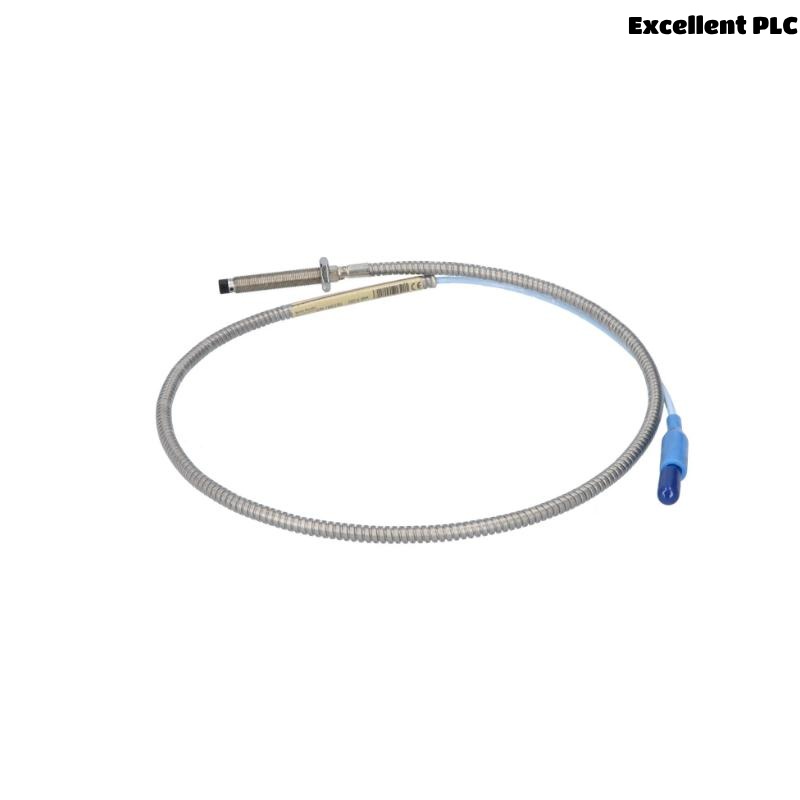

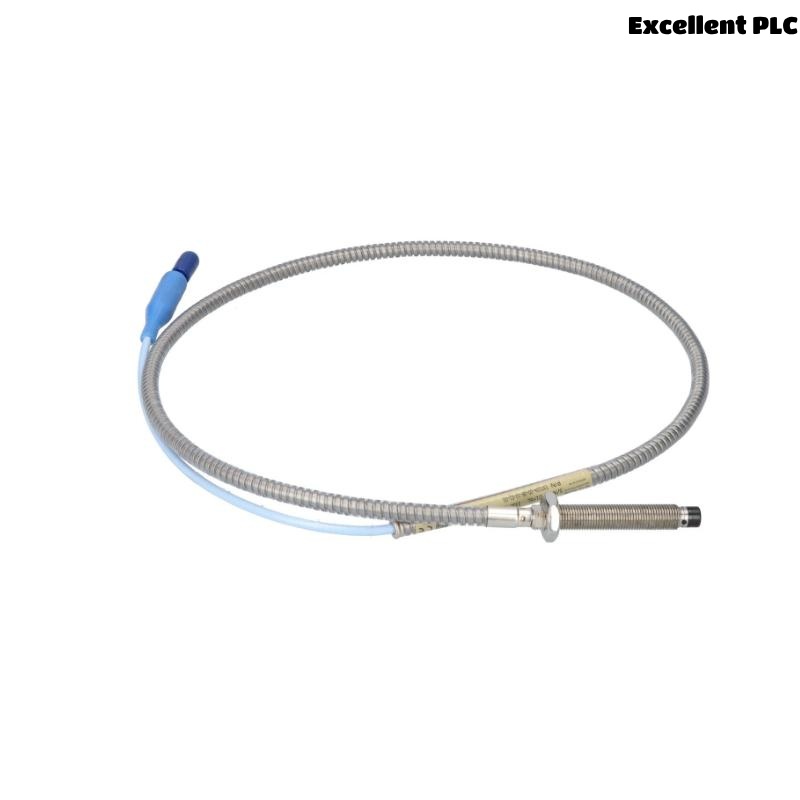

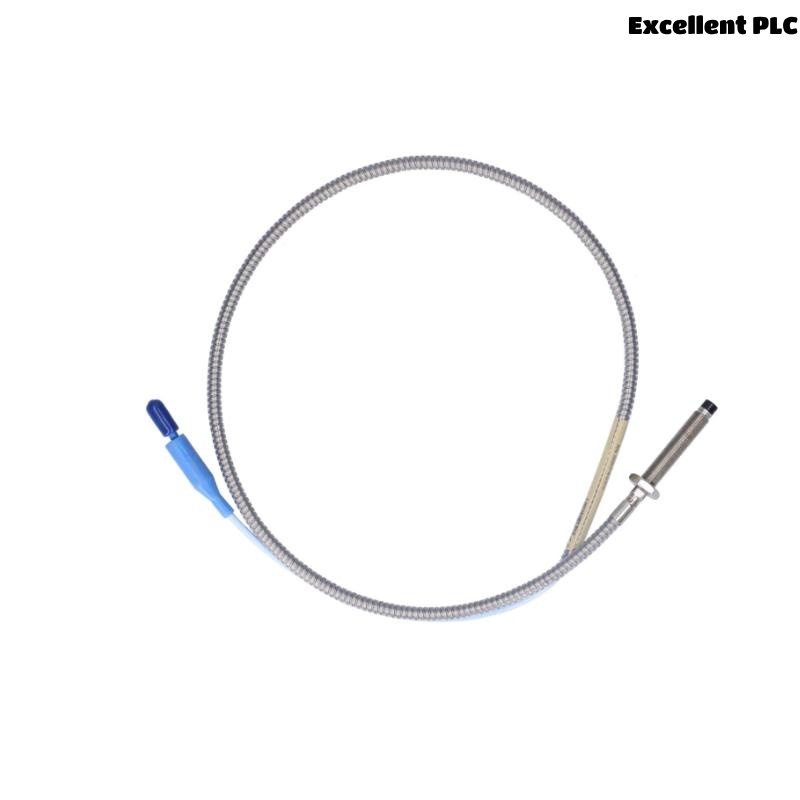

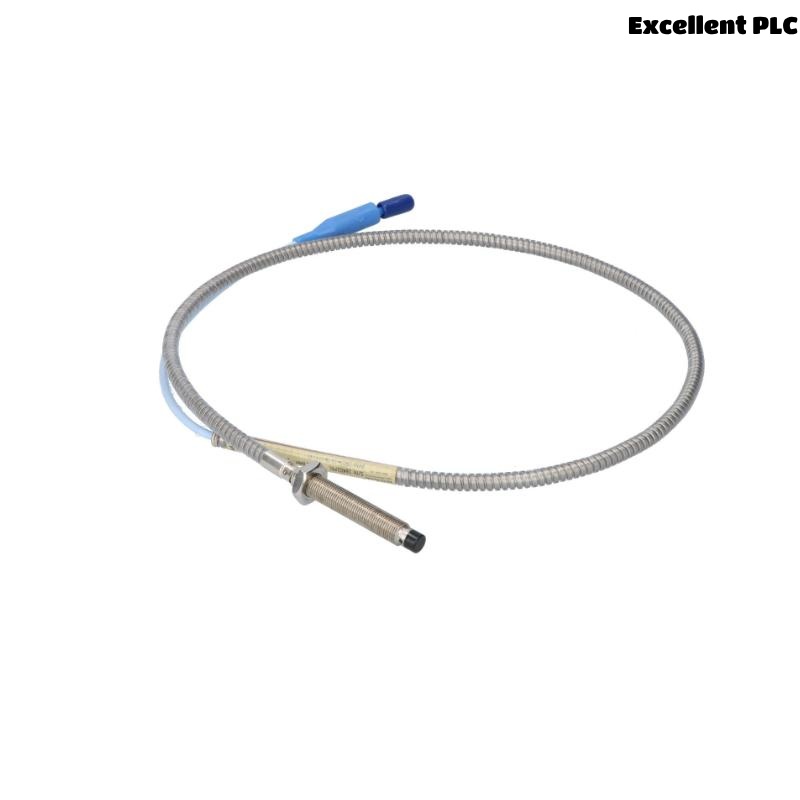

The Bently Nevada 330104-00-08-10-02 is part of the 3300 XL 8 mm series, designed for precise non-contact vibration and position monitoring in rotating machinery. It features an armored M10x1 thread probe with a total length of 1.0 meter and is fully compatible with the 3300 XL Proximitor Sensor and extension cables.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330104-00-08-10-02 |

| Probe Type | Armored, M10x1 thread |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Tip Diameter | 8 mm |

| Cable Type | 75Ω triaxial, FEP-insulated |

| Connector Type | Miniature coaxial ClickLoc |

| Operating Temperature | -52°C to +177°C |

| Recommended Gap | 1.27 mm (50 mils) |

| Sensitivity | 7.87 V/mm (200 mV/mil) ±5% |

| Case Material | Stainless Steel (AISI 303 or 304) |

| Minimum Cable Bend Radius | 25.4 mm (1.0 inch) |

| Compliance | API 670, CE, RoHS, FCC Part 15, SIL2/SIL3 |

Applications

-

Vibration monitoring of fluid-film bearing machinery

-

Shaft position and radial displacement measurement

-

Speed and phase reference (Keyphasor) detection

-

Turbine and compressor condition monitoring

-

Critical machinery overspeed protection (with guidelines)

Advantages

-

No calibration needed when replacing components

-

Fully interchangeable probe, cable, and sensor

-

Withstands harsh environments with armored design

-

FluidLoc option prevents oil migration

-

RFI/EMI resistant; suitable for use in fiberglass enclosures

-

API 670 compliant for linearity and mechanical specs

-

ClickLoc connectors for secure and tool-free connection

Frequently Asked Questions (FAQ)

Q1: What is the probe’s measuring range?

A1: 0.25 mm to 2.3 mm (10 to 90 mils), linear and accurate.

Q2: Does this model meet API 670?

A2: Yes, it complies with the mechanical and performance requirements of API 670.

Q3: Is recalibration needed during component replacement?

A3: No, it supports full interchangeability without recalibration.

Q4: Can the probe be used in hazardous areas?

A4: Yes, it’s certified for Class I, Zone 0 and Zone 2 applications.

Q5: What is the output sensitivity?

A5: 7.87 V/mm (200 mV/mil) ±5%.

Q6: What size shaft is recommended for use?

A6: Minimum diameter 50.8 mm; recommended 76.2 mm.

Q7: What is the total length and weight of this model?

A7: 1.0 meter; approximately 0.323 kg.

Q8: What connector does it use?

A8: Gold-plated ClickLoc connector, finger-tight with locking click.

Q9: Can this probe operate at high temperatures?

A9: Yes, up to +177°C standard; up to +218°C with ETR version.

Q10: Is it resistant to EMI/RFI interference?

A10: Yes, designed with excellent immunity without special shielding.

Related Models from the Same Series

| Model Number | Thread Type | Length | Armor | Connector | Notes |

|---|---|---|---|---|---|

| 330104-00-06-10-02 | M10x1 | 0.6 m | Yes | ClickLoc | Shorter armored version |

| 330104-01-05-50-02 | M10x1 | 5.0 m | Yes | ClickLoc | Long armored version |

| 330103-00-02-10-02 | M10x1 | 1.0 m | No | ClickLoc | Unarmored version |

| 330101-00-08-10-02 | 3/8-24 UNF | 1.0 m | Yes | ClickLoc | Imperial thread variant |

| 330102-00-20-10-02 | 3/8-24 UNF | 2.0 m | Yes | ClickLoc | Longer armored probe |

| 330105-02-12-10-02 | 3/8-24 UNF | 1.0 m | No | ClickLoc | Reverse mount style |

Popular Bently Nevada Models

| Model Number | Product Type | Key Feature | Application |

|---|---|---|---|

| 3500/42M-01-00 | Seismic Monitor | Proximitor interface monitoring | Vibration monitoring |

| 3500/22M | Data Interface | Communication with System 1 | Diagnostic systems |

| 330180-91-CN | Proximitor Sensor | 1.0m system length | Works with 3300 XL probes |

| 330104-00-06-10-11-00 | Proximity Probe | M10x1, armored, FluidLoc cable | Oil migration prevention |

| 3500/15 | Power Supply Module | Redundant rack power | 3500 Series systems |

| 330103-00-02-10-02 | Proximity Probe | Metric, unarmored, 1.0m | Space-constrained areas |

Excellent PLC

Excellent PLC