| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

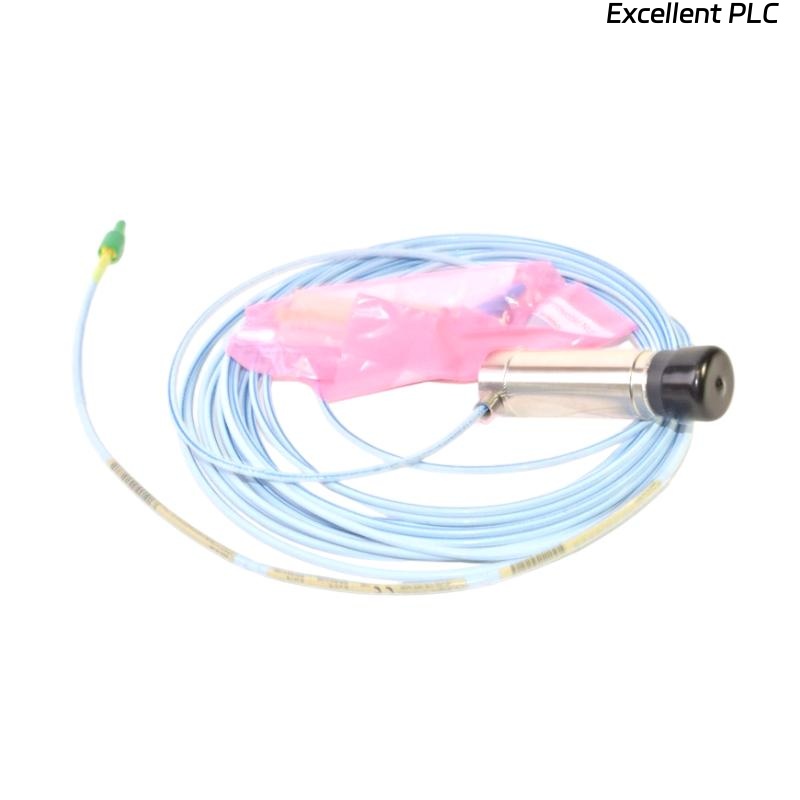

The Bently Nevada 330104-00-11-10-02-05 is a premium proximity probe from the 3300 XL 8 mm series, engineered for accurate, non-contact measurement of shaft position and vibration in rotating machinery. As part of GE’s Bently Nevada machinery protection portfolio, this model delivers precise displacement readings for real-time monitoring of critical equipment like turbines, compressors, motors, and pumps.

With an 8 mm sensing tip, M10 x 1 threaded body, and an integral 1.1-meter cable, this model provides high reliability and ease of installation in both OEM and retrofit environments. The “3300 XL” system—consisting of the probe, extension cable, and Proximitor® sensor—is factory-matched for exceptional accuracy and long-term signal integrity.

Designed to perform in high-temperature, high-vibration, and electrically noisy environments, this probe helps prevent costly failures by enabling predictive and preventive maintenance strategies.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | 3300 XL 8 mm Proximity Probe |

| Part Number | 330104-00-11-10-02-05 |

| Series | Bently Nevada 3300 XL |

| Sensing Tip Diameter | 8 mm |

| Thread Type | M10 x 1 |

| Body Length | 55 mm (not including cable) |

| Total Length | 1 meter |

| Connector Type | Right-angle coaxial connector |

| Target Material | 4140 Steel (standard calibration material) |

| Linear Range | 2 mm (80 mils) |

| System Accuracy | ±0.076 mm (±3 mils) typical with matched system components |

| Frequency Response | 0–10 kHz (depends on installation and system configuration) |

| Mounting | Threaded mount with lock nut |

| Temperature Range | −35°C to +177°C (−31°F to +350°F) |

| Humidity | 0–95% RH, non-condensing |

| Vibration Tolerance | 10 g peak, 10–2,000 Hz |

| Shock Resistance | 1000 g, 1 ms duration |

| Environmental Protection | IP65 (with proper cable sealing) |

| Weight | 0.323 kg |

Applications

The 330104-00-11-10-02-05 is widely used in vibration and position monitoring systems across multiple industrial environments, including:

-

Gas and Steam Turbines – Continuous monitoring of rotor vibration and shaft position.

-

Centrifugal Compressors – Ensures safe operation by detecting proximity anomalies.

-

Electric Motors – Tracks radial and axial displacement to prevent bearing damage.

-

Pumps and Fans – Identifies unbalance, cavitation, or shaft deflection.

-

Generators and Alternators – Enables condition-based maintenance through real-time feedback.

-

Gearboxes – Monitors internal movement and alignment of rotating gears.

Product Advantages

-

High-Precision Measurement – Provides stable, repeatable readings for machine health diagnostics.

-

Factory-Calibrated System – Matched components ensure exceptional accuracy and linearity.

-

Compact M10 Thread Size – Allows installation in limited-space applications.

-

Durability Under Harsh Conditions – Operates in high temperatures, shock, and vibration without signal drift.

-

Low Electromagnetic Interference (EMI) – Excellent shielding for industrial environments.

-

Easy Integration – Seamless compatibility with Bently Nevada 3300 XL systems and Proximitor® sensors.

Frequently Asked Questions (FAQ)

-

What is the main function of this probe?

It measures the distance between the probe tip and a metal surface (typically a rotating shaft) without physical contact. -

Is this model part of a complete monitoring system?

Yes. It is used with a matching extension cable and Proximitor® sensor as part of the 3300 XL system. -

Can it be used in high-temperature areas?

Yes, it supports operating temperatures up to 177°C (350°F). -

What’s the difference between this and a 5 mm probe?

The 8 mm probe offers a longer linear range and is suited for standard installations with more space. -

How is this probe installed?

It’s mounted using its threaded body and secured with a lock nut; alignment and gap spacing are critical. -

Is the cable replaceable?

No, the integral cable is permanently attached. Any damage requires replacing the entire probe. -

Can it be used in hazardous areas?

The probe itself is not intrinsically safe, but the system can be made compliant with proper certified components. -

What target materials are supported?

Factory calibration is based on 4140 steel. Other materials may affect sensitivity unless recalibrated. -

Is the connector shielded?

Yes, the coaxial connector is shielded against electrical noise and must be properly sealed. -

How does it interact with the Proximitor® sensor?

It transmits the signal from the sensing tip through the extension cable to the Proximitor® module for signal processing.

Related Models – 3300 XL Series Probes

| Model | Description | Cable Length | Thread Type | Tip Diameter |

|---|---|---|---|---|

| 330104-00-12-10-01 | M10 thread, 1.2 m cable | 1.2 m | M10 x 1 | 8 mm |

| 330104-00-25-10-01 | M10 thread, 2.5 m cable | 2.5 m | M10 x 1 | 8 mm |

| 330104-00-05-10-01 | M10 thread, 0.5 m cable | 0.5 m | M10 x 1 | 8 mm |

| 330104-00-08-10-02-05 | M10 thread, 0.8 m cable, angled conn. | 0.8 m | M10 x 1 | 8 mm |

| 330104-00-20-10-02-05 | M10 thread, 2.0 m cable, key conn. | 2.0 m | M10 x 1 | 8 mm |

| 330103-00-60-10-01 | 1/4-28 UNF thread, armored cable | 1.5 m | 1/4-28 UNF | 8 mm |

Popular Bently Nevada Models – Other Product Lines

| Model | Product Type | Application | Mounting Format |

|---|---|---|---|

| 3500/42M | Proximitor® Monitor Module | Shaft vibration and position | Rack-mounted |

| 3500/15 | Power Supply Module | Powers 3500 system racks | Modular rack unit |

| 3500/22M | Communications Gateway | Network interface for 3500 data | Rack-mounted |

| 3701/40 | Machinery Monitor | Standalone protection system | Panel-mount DIN format |

| 330180-91-05 | XL Extension Cable (5 meters) | Probe to sensor extension | Coaxial shielded cable |

| 190501-00-00 | Velomitor® Velocity Sensor | Seismic vibration measurement | Industrial sensor |

Excellent PLC

Excellent PLC