| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

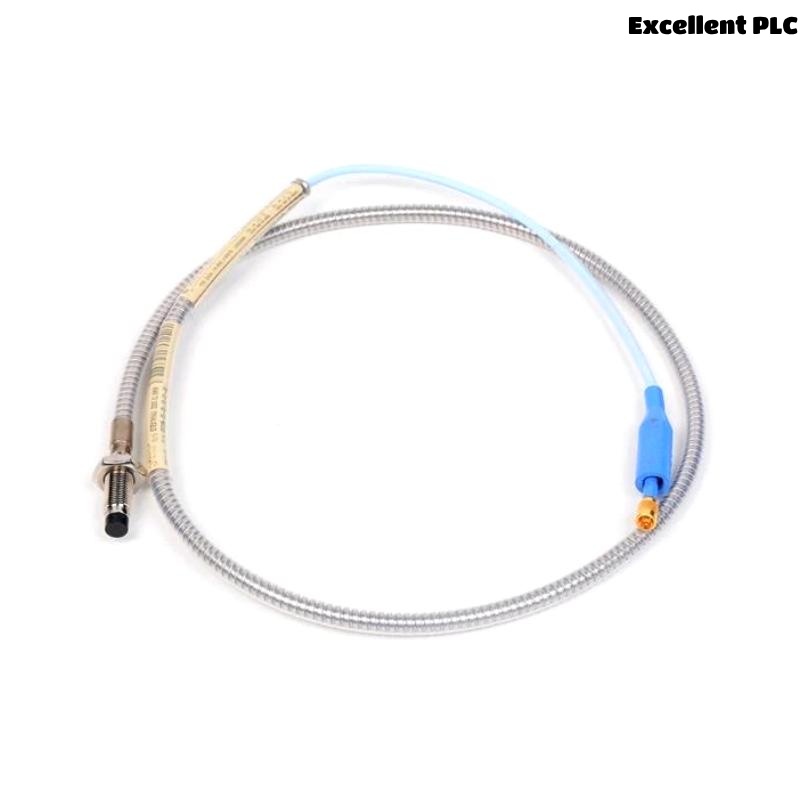

The Bently Nevada 330104-00-12-05-02-00 is an advanced 8 mm proximity probe designed for the precise measurement of shaft vibration and position in rotating equipment. This probe, part of the highly regarded 3300 XL series, is widely used across various industries such as power generation, oil and gas, and manufacturing, offering accurate, reliable, and durable performance.

Measuring just 0.5 meters in total length and weighing 0.162 kg, this metric version of the proximity probe integrates seamlessly into systems for continuous condition monitoring. The Bently Nevada 330104-00-12-05-02-00 provides high performance in even the harshest environments, ensuring that your critical machinery stays in optimal condition, and allowing early fault detection to prevent costly breakdowns and downtime.

This probe is engineered for easy installation, long-term operation, and minimal maintenance, making it a trusted solution for industrial machinery monitoring. It provides non-contact eddy current sensing technology, offering superior sensitivity and the ability to detect even the smallest changes in machine condition.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330104-00-12-05-02-00 |

| Probe Tip Diameter | 8 mm |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Sensing Technology | Eddy Current |

| Measurement Range | Up to 1.27 mm (50 mils) typical |

| Operating Temperature | -40°C to +120°C |

| Mounting Type | Threaded Mount |

| Connector Type | Metric |

| Probe Material | Stainless Steel |

| Vibration Resistance | High |

| Shielding | Yes |

Product Applications

The Bently Nevada 330104-00-12-05-02-00 proximity probe is used in a variety of applications across industries to monitor the health of rotating equipment. Its high sensitivity and non-contact design make it suitable for detecting shaft displacement and vibration in:

-

Turbines: Ensures reliable performance by monitoring shaft position and vibration, helping to prevent damage.

-

Compressors: Detects imbalance, misalignment, or wear to ensure smooth and efficient operation.

-

Pumps: Provides accurate vibration readings, allowing maintenance teams to monitor and address potential issues before they lead to failures.

-

Electric Motors: Prevents motor breakdowns by monitoring vibrations that could signal mechanical problems.

-

Generators: Critical for monitoring the condition of generator shafts to prevent unexpected shutdowns or mechanical damage.

-

Gearboxes: Used to monitor gear alignment and vibrations, helping identify issues such as misalignment, wear, or damage.

This probe is commonly applied in the monitoring of machinery that operates under continuous load conditions where detecting potential failures early can prevent catastrophic damage, minimize unscheduled downtime, and optimize maintenance cycles.

Product Advantages

-

High Precision Sensing: Provides reliable measurements with its eddy current technology, ideal for detecting minor shifts in machine condition.

-

Non-Contact Design: This reduces wear and tear on the sensor, ensuring it performs accurately for long periods.

-

Rugged Construction: Made from stainless steel, this probe is highly resistant to corrosion and physical damage, making it suitable for harsh environments.

-

Compact and Lightweight: At just 0.162 kg and 0.5 meters in length, the probe is easy to integrate into your machinery without adding unnecessary bulk.

-

Temperature Resistant: Withstanding a wide operating temperature range of -40°C to +120°C, it performs reliably in extreme environments.

-

Easy Installation: The threaded mount design simplifies installation in a wide range of industrial applications.

-

Enhanced Durability: Built for long-term operation, minimizing the need for frequent replacements or maintenance.

-

Signal Integrity: Shielded design ensures that it operates effectively even in electrically noisy environments.

-

Ideal for Predictive Maintenance: Facilitates early detection of equipment faults, allowing for timely intervention before failures occur.

-

Global Trust: Bently Nevada is a recognized leader in vibration monitoring, ensuring the probe meets high-quality standards.

Frequently Asked Questions (FAQ)

-

What is the primary use of the Bently Nevada 330104-00-12-05-02-00 probe?

It is used to measure the vibration and position of rotating machinery, helping to detect faults early. -

What is the length and weight of this proximity probe?

The total length is 0.5 meters, and the weight is 0.162 kg. -

What is the diameter of the probe tip?

The probe tip diameter is 8 mm. -

What type of technology does this probe use for sensing?

It uses eddy current technology, which allows for non-contact measurement. -

What is the typical measurement range of this probe?

The typical measurement range is up to 1.27 mm (50 mils). -

Can this probe be used in high-temperature environments?

Yes, it operates within a temperature range of -40°C to +120°C. -

What is the mounting type of the probe?

The probe uses a threaded mounting design for easy installation. -

Is the probe resistant to vibration?

Yes, it is built to withstand high levels of vibration, making it ideal for harsh environments. -

How does the non-contact design of the probe benefit performance?

The non-contact design prevents wear and tear, leading to increased reliability and longer service life. -

What industries commonly use this probe?

The probe is used in industries such as power generation, oil & gas, manufacturing, and more, to monitor rotating machinery.

Recommended Related Models

| Model Number | Description |

|---|---|

| 330104-00-08-10-02-00 | 8 mm Proximity Probe (metric connector) |

| 330104-00-07-10-02-00 | 8 mm Proximity Probe with standard connector |

| 330110-00-07-10-02-00 | High Temperature 8 mm Proximity Probe |

| 330106-00-07-10-02-00 | 5 mm Proximity Probe (metric) |

| 330180-91-05 | Reverse Mount Proximity Probe |

| 330130-00-07-10-02-00 | Ruggedized 8 mm Proximity Probe |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/05-03-02-00 | System Rack for 3500 Monitoring Systems |

| 3500/22-01-01-00 | Transient Data Interface Module |

| 3500/40M-01-00 | Proximitor Monitor |

| 3500/42M-01-00 | Vibration Monitor |

| 330103-00-05-10-02-00 | High Temperature 8 mm Proximity Probe |

| 330106-05-30-10-02-00 | 5 mm Proximity Probe, Panel Mount |

Excellent PLC

Excellent PLC