| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

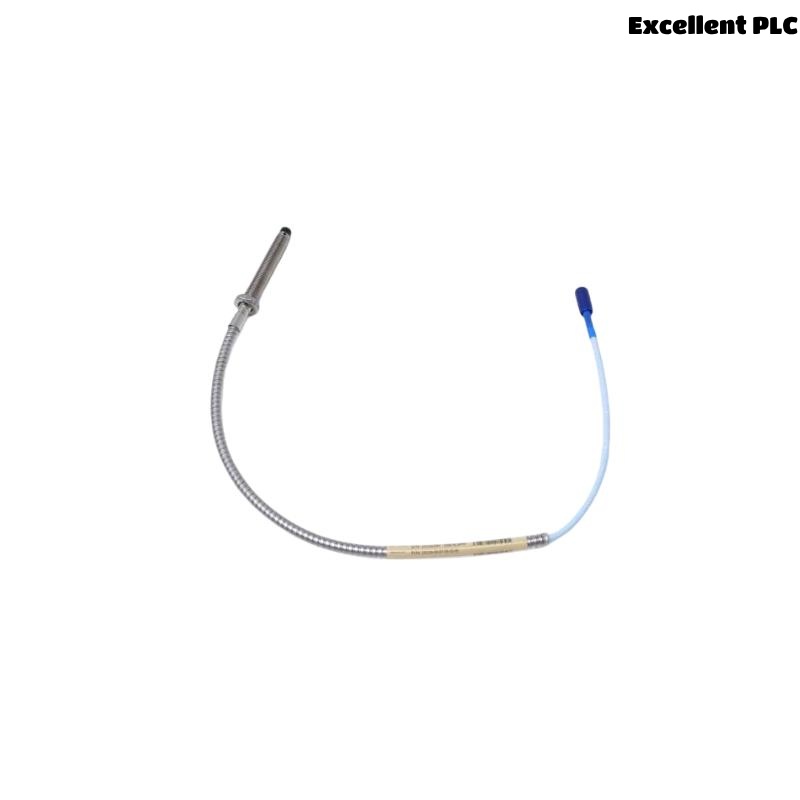

The Bently Nevada 330104-00-13-10-01-05 3300 XL 8 mm Proximity Probe is a highly accurate and reliable sensor designed for use in industrial applications. Part of the Bently Nevada 3300 XL series, this proximity probe offers superior performance in monitoring shaft positions, vibrations, and other key measurements in machinery. The 8 mm version is specifically designed for industrial environments that require precise measurements for predictive maintenance and condition monitoring.

Known for its rugged durability and exceptional reliability, the 3300 XL 8 mm proximity probe is ideal for industries such as power generation, oil and gas, petrochemical, and manufacturing. By integrating this probe into a machinery condition monitoring system, companies can optimize their maintenance schedules, increase operational efficiency, and reduce unplanned downtimes.

Product Features and Advantages

-

High Precision Measurement: The 3300 XL 8 mm proximity probe offers highly accurate readings, providing precise measurements of the shaft position and vibration in industrial machinery.

-

Robust Design: Built to withstand harsh industrial conditions, the probe features a durable construction that ensures long-lasting performance and minimal maintenance.

-

Easy Integration: The 3300 XL 8 mm probe is designed for easy integration into existing machinery condition monitoring systems, allowing for seamless setup and operation.

-

Long Measurement Range: With its superior range, the probe provides consistent and reliable performance across a wide range of operational conditions.

-

High Sensitivity: The probe is highly sensitive to minute changes in shaft position, ensuring accurate monitoring of critical machinery components.

-

Versatile Applications: This probe is suitable for use in a wide range of industries, from power plants to petrochemical facilities, where precision monitoring is essential.

Specifications Table

| Parameter | Value |

|---|---|

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Diameter | 8 mm |

| Material | Stainless Steel |

| Temperature Range | -40°C to +120°C |

| Mounting Style | Integral |

| Sensitivity | High Sensitivity |

| Output Type | Linear (Voltage/Current) |

| Applications | Vibration, Shaft Position Monitoring |

| Compatibility | Compatible with 3300 XL system |

Applications

The Bently Nevada 330104-00-13-10-01-05 3300 XL 8 mm proximity probe has diverse applications in industries that require precise machinery monitoring. Some of the common applications include:

-

Condition Monitoring Systems: Used as a critical component in machinery condition monitoring, the probe helps identify faults early, enabling predictive maintenance and reducing unplanned downtime.

-

Power Generation: In power plants, this probe is used to monitor rotating machinery such as turbines, generators, and pumps to ensure smooth and continuous operations.

-

Oil & Gas: For offshore and onshore oil rigs, the 3300 XL probe is essential in monitoring compressors, pumps, and motors in extreme environmental conditions.

-

Petrochemical: In petrochemical plants, the proximity probe is used to monitor high-speed rotating equipment like compressors and mixers, ensuring high uptime and preventing mechanical failure.

-

Manufacturing: In high-speed manufacturing processes, it is used to track shaft vibration, ensuring machinery runs efficiently and detecting any mechanical issues before they cause major breakdowns.

Advantages

-

Increased Uptime: By enabling condition monitoring, the 3300 XL proximity probe helps prevent unexpected equipment failure, leading to increased uptime and better resource utilization.

-

Accurate Data for Predictive Maintenance: The high sensitivity and accuracy of the probe provide valuable data that can be used to predict maintenance needs, helping avoid costly repairs and downtime.

-

Long Service Life: Thanks to its rugged stainless-steel construction and resistance to extreme environmental conditions, the 3300 XL probe has a long service life, reducing the frequency of replacements.

-

Cost-Effective: The ability to detect early warning signs of failure saves companies from expensive repairs, making the 3300 XL 8 mm probe a cost-effective solution for long-term machinery health monitoring.

-

Wide Compatibility: This probe integrates seamlessly with other Bently Nevada 3300 XL products, providing flexibility and ease of use within an existing system.

-

Reliability in Harsh Environments: The probe’s design allows it to perform reliably in high-temperature, high-vibration, and other harsh industrial environments.

Frequently Asked Questions (FAQ)

-

Q: What is the main purpose of the Bently Nevada 330104-00-13-10-01-05 proximity probe?

-

A: The probe is designed to measure shaft position and vibration in industrial machinery, providing critical data for machinery condition monitoring and predictive maintenance.

-

-

Q: What industries can benefit from using the 3300 XL 8 mm proximity probe?

-

A: The probe is suitable for industries such as power generation, oil and gas, petrochemical, and manufacturing, where precise machinery monitoring is necessary.

-

-

Q: How does the 3300 XL 8 mm proximity probe help with predictive maintenance?

-

A: By providing accurate readings of shaft position and vibrations, the probe allows operators to detect potential issues early, enabling maintenance actions to be taken before a failure occurs.

-

-

Q: Is the Bently Nevada 330104-00-13-10-01-05 proximity probe easy to install?

-

A: Yes, the probe is designed for easy integration into existing machinery condition monitoring systems, making installation quick and straightforward.

-

-

Q: What is the temperature range for the Bently Nevada 3300 XL 8 mm proximity probe?

-

A: The probe operates in a temperature range of -40°C to +120°C, making it suitable for use in a variety of industrial environments.

-

-

Q: How durable is the Bently Nevada 330104-00-13-10-01-05 proximity probe?

-

A: The probe is made of stainless steel and designed to withstand harsh industrial conditions, ensuring long-lasting performance even in high-vibration and high-temperature environments.

-

-

Q: What output type does the Bently Nevada 330104-00-13-10-01-05 proximity probe provide?

-

A: The probe provides a linear output in either voltage or current, depending on the system configuration.

-

-

Q: Can the 3300 XL 8 mm proximity probe be used with other Bently Nevada products?

-

A: Yes, it is fully compatible with other Bently Nevada 3300 XL system components, allowing for seamless integration into existing setups.

-

-

Q: What is the weight of the Bently Nevada 330104-00-13-10-01-05 proximity probe?

-

A: The probe weighs 0.323 kg, making it lightweight and easy to handle during installation.

-

-

Q: What is the total length of the Bently Nevada 330104-00-13-10-01-05 proximity probe?

-

A: The probe has a total length of 1.0 meter, making it suitable for a wide range of machinery applications.

-

Recommended Models

Related Models from the Same Series

| Model | Description | Key Features |

|---|---|---|

| 330104-00-13-10-01-04 | 3300 XL 5 mm Proximity Probe (Metric) | Smaller probe diameter, similar functionality |

| 330104-00-13-10-01-02 | 3300 XL 8 mm Proximity Probe (Imperial) | Imperial version of the 8 mm probe |

| 330104-00-13-10-01-08 | 3300 XL 12 mm Proximity Probe (Metric) | Larger diameter for specific high-vibration environments |

| 330104-00-13-10-01-09 | 3300 XL 8 mm Proximity Probe (Metric) | Long cable version for extended reach |

| 330104-00-13-10-01-03 | 3300 XL 8 mm Proximity Probe (High Temperature) | Enhanced performance for high-temperature applications |

| 330104-00-13-10-01-07 | 3300 XL 8 mm Proximity Probe (Extended Range) | Probe with extended measurement range for complex systems |

Popular Models from Bently Nevada

| Model | Description | Key Features |

|---|---|---|

| 3300/05-01-01 | 3300 XL Vibration Transmitter | Works with proximity probes to monitor vibrations |

| 3300/03-01-01 | 3300 XL High-Speed Vibration Sensor | High-speed vibration monitoring for rotating machinery |

| 3300/04-01-01 | 3300 XL Shaft Position Transducer | Monitors shaft position with high accuracy |

| 3300/01-01-01 | 3300 XL Vibration Probe | Essential for accurate vibration measurement |

| 3300/02-01-01 | 3300 XL Digital Transducer | Digital conversion for enhanced data analysis |

| 3300/06-01-01 | 3300 XL Extension Cable | Extended reach for probes in large machinery setups |

Excellent PLC

Excellent PLC