| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

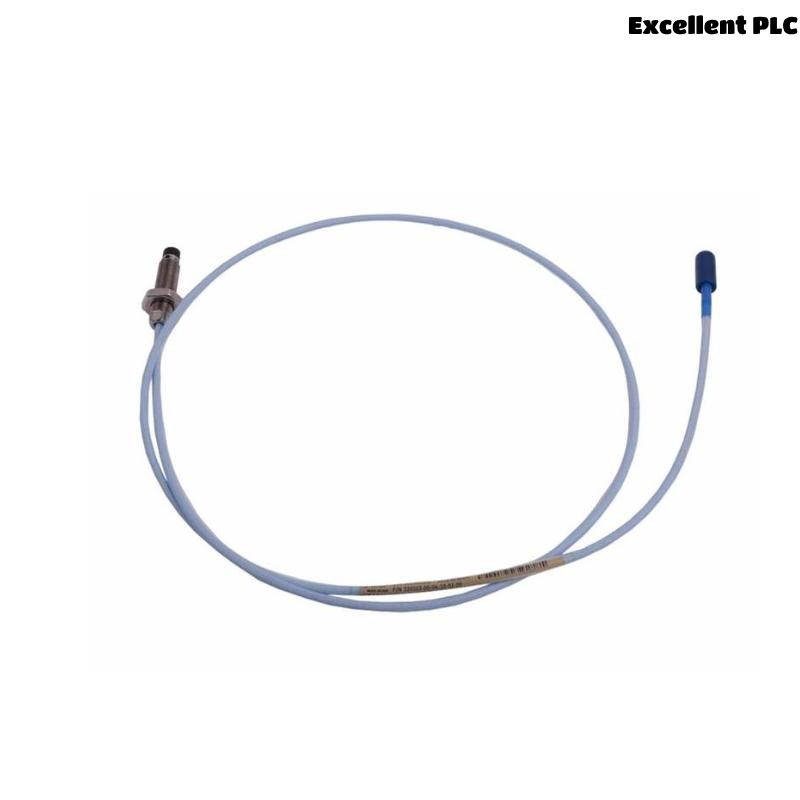

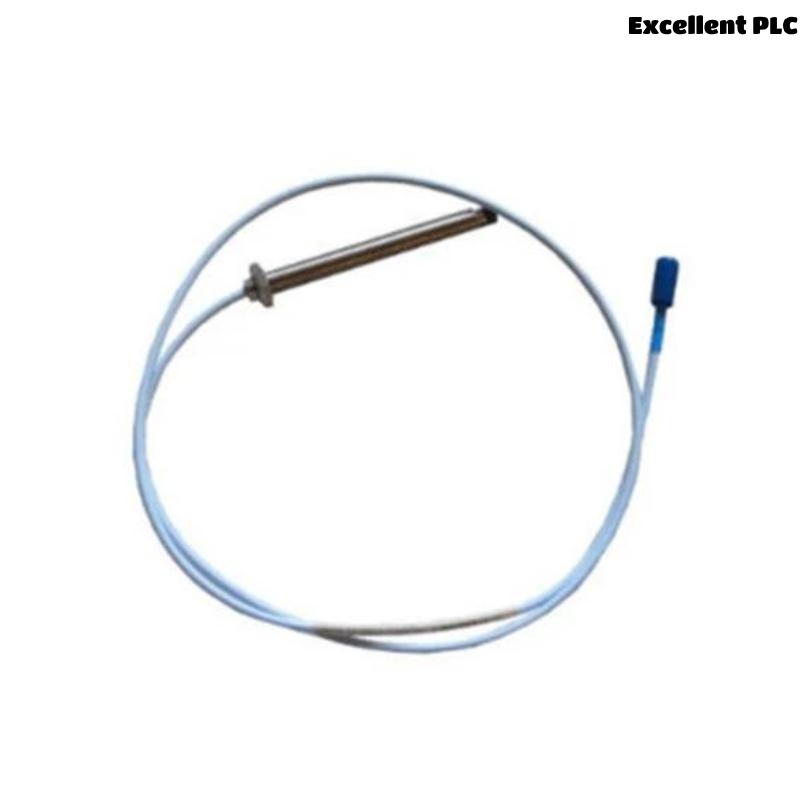

The Bently Nevada 330104-00-20-10-11-05 3300 XL 8 mm Proximity Probe is a premium-quality non-contact sensor designed to deliver precise measurements of vibration and shaft displacement in critical rotating machinery. It is part of the trusted 3300 XL series, known for its reliability, ruggedness, and performance in harsh industrial environments.

This model is configured with a 20-meter probe cable, a 10-meter extension cable, and an 11-meter connector cable. The probe is built with corrosion-resistant stainless steel and offers excellent protection against environmental contaminants, making it highly suitable for heavy-duty applications across industries like oil and gas, power generation, and chemical processing.

Technical Specifications

| Specification | Description |

|---|---|

| Model Number | 330104-00-20-10-11-05 |

| Series | 3300 XL |

| Probe Tip Diameter | 8 mm |

| Measurement Principle | Eddy Current (Non-contact displacement) |

| Linear Range | 0.25 mm to 2.0 mm |

| Sensitivity | -200 mV/mm (typical) |

| Output Voltage | -200 mV to -22 V |

| Operating Temperature | -40°C to +100°C |

| Storage Temperature | -51°C to +177°C |

| Environmental Protection | IP68 (hermetically sealed) |

| Housing Material | AISI 304 Stainless Steel |

| Target Material | Calibrated for 4140 Steel |

| Connector Type | 3-slot male connector |

| Dimensions | Total Length : 1.0 meter |

| Weight | 0.323 kg |

| Compliance | CE, RoHS; optional ATEX version available |

Industry Applications

-

Oil & Gas: Monitoring compressors, turbines, and pumps on rigs and refineries

-

Power Generation: Shaft vibration and displacement analysis in turbines and generators

-

Petrochemical: Real-time condition monitoring for high-speed rotating machinery

-

Steel & Metals: Equipment diagnostics in harsh high-temperature environments

-

Water Utilities: Monitoring of large pumps and motor systems

-

Paper & Pulp: Ensuring continuous performance of critical process machinery

-

Mining: Monitoring crushers, fans, and mills in abrasive environments

Key Advantages

-

Long-Distance Compatibility: Extended 20 m probe for remote sensor placement

-

Accurate Performance: Highly linear output for precise displacement and vibration monitoring

-

Environmentally Robust: Resistant to moisture, dust, oil, and corrosive chemicals

-

Flexible Installation: Long connector and extension cable allow versatile routing

-

Field-Proven Design: Widely adopted in critical machinery monitoring globally

-

System Integration: Fully compatible with 3300 XL and Bently Nevada monitoring systems

-

Reduced Downtime: Enables predictive maintenance strategies

-

Safety Compliance: CE and RoHS compliant with hazardous area options available

Frequently Asked Questions (FAQ)

-

What is the total cable configuration for this probe?

It includes a 20 m probe cable, 10 m extension cable, and an 11 m connector cable. -

Is the probe suitable for hazardous environments?

Yes, ATEX-certified versions are available upon request. -

What is the typical application of this probe?

It is commonly used for non-contact vibration and displacement monitoring of rotating equipment. -

What output does the probe provide?

It delivers a voltage signal proportional to the distance from the shaft, typically -200 mV/mm. -

Is it compatible with all 3300 XL systems?

Yes, the probe is fully compatible with the Bently Nevada 3300 XL monitoring systems. -

What material is the housing made from?

The probe features a corrosion-resistant AISI 304 stainless steel housing. -

Can the probe be submerged in water?

Yes, it is rated IP68 and is hermetically sealed, suitable for submersion. -

What is the operating temperature range?

It operates between -40°C and +100°C. -

Is calibration required for different shaft materials?

Yes, factory calibration is typically for 4140 steel; other materials may require recalibration. -

How does this model differ from shorter cable versions?

This model allows longer-distance placement between the sensor and monitoring device, which is ideal for large industrial setups.

Recommended Related Models

| Model Number | Description |

|---|---|

| 330104-00-18-10-02-CN | 18 m probe / 10 m extension / 2 m connector |

| 330104-00-12-10-02-05 | 12 m probe / 10 m extension / 2 m connector |

| 330104-00-05-05-11-05 | 5 m probe / 5 m extension / 11 m connector |

| 330104-00-10-05-01-CN | 10 m probe / 5 m extension / 1 m connector |

| 330130-080-00-00 | XL Series Extension Cable, 8 m |

| 330101-00-14-10-02-05 | 3300 XL 8 mm Probe, Standard Configuration |

Popular Bently Nevada Models

| Model Number | Product Name |

|---|---|

| 330104-01-08-50-01-CN | 8 mm Probe with extended cable (China version) |

| 330104-00-07-10-02-05 | 7 m Probe with 10 m extension and 2 m connector |

| 330104-04-10-05-02-05 | High-temp 8 mm Proximity Probe |

| 330130-045-01-05 | 4.5 m XL Extension Cable |

| 3300 XL Monitor | Vibration Monitoring System |

Excellent PLC

Excellent PLC