| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

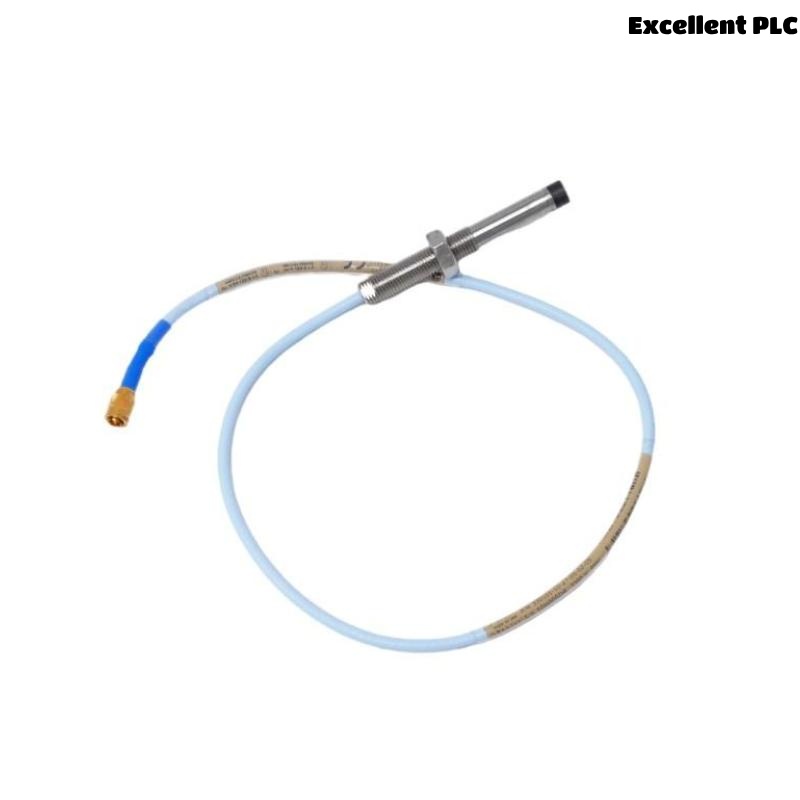

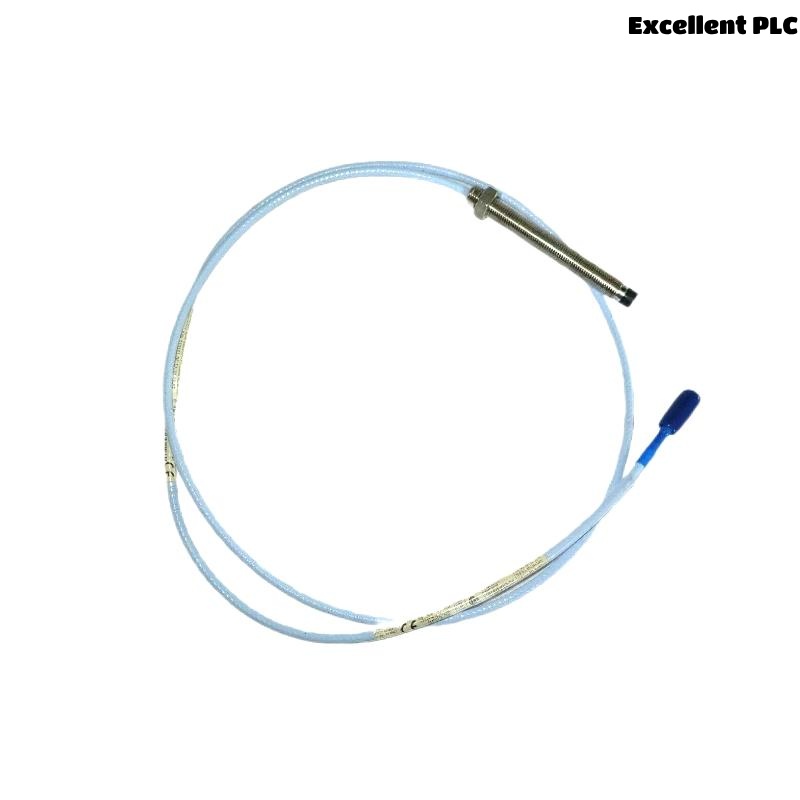

The Bently Nevada 330104-01-05-05-02-00 3300 XL 8 mm Proximity Probe is a high-accuracy, non-contact eddy current sensor designed to provide precise measurement of shaft vibration, axial thrust, and shaft position on critical rotating machinery.

Part of the industry-leading 3300 XL 8 mm Series, this probe features an 8 mm sensing tip and a 0.5 meter total length, making it ideal for installations requiring mechanical cable protection. Engineered to deliver excellent long-term performance and stability, this probe ensures seamless integration with 3300 XL Proximitor Sensors and compatible Bently Nevada monitoring systems.

Widely deployed across oil & gas, power generation, petrochemical, refining, and heavy industry sectors, the 330104-01-05-05-02-00 is trusted by engineers and maintenance teams for safeguarding their most valuable rotating assets.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330104-01-05-05-02-00 |

| Product Type | 3300 XL 8 mm Proximity Probe |

| Sensing Technology | Eddy current, non-contact |

| Probe Tip Diameter | 8 mm |

| Probe Tip Material | PPS (Polyphenylene sulfide) |

| Thread Size | 3/8-24 UNF |

| Total Length | 0.5 meter |

| Cable Armor | Armored |

| Connector Type | Miniature coaxial connector |

| Target Material | 4140 steel (factory calibrated) |

| Measurement Range | 2 mm (80 mils), linear range |

| Scale Factor | 200 mV/mil (7.87 mV/μm) nominal |

| System Linear Range | 80 mils (2.0 mm) |

| Non-Linearity | ≤ ±0.75% of full scale (typical) |

| Frequency Response | 0 Hz to 10 kHz (±3 dB) |

| Operating Temperature (Probe) | -51 °C to +177 °C |

| Operating Temperature (System) | -35 °C to +120 °C |

| Humidity | 100% condensing, sealed |

| Shock / Vibration Tolerance | 10 g @ 10-2,000 Hz |

| Pressure Rating | 5 bar (sealed probe tip) |

| Certifications | CE, ATEX Zone 2, CSA, IECEx |

| Weight | 0.162 kg |

Applications

The 330104-01-05-05-02-00 proximity probe is designed to monitor a broad range of critical rotating equipment, such as:

-

Gas Turbines

Shaft vibration and thrust position monitoring. -

Steam Turbines

Measurement of axial rotor movement and bearing performance. -

Centrifugal Compressors

Shaft alignment, imbalance, and vibration tracking. -

Reciprocating Compressors

Detects rod drop, bearing clearance, and dynamic movement. -

Industrial Motors & Generators

Continuous monitoring of shaft vibration and position. -

Pumps, Fans, Gearboxes

Condition-based maintenance for rotating elements. -

Oil & Gas and Power Generation

Essential component in protection systems for turbines and compressors.

Product Advantages

-

Proven Accuracy

Stable, linear response of 200 mV/mil across full range. -

Robust Armored Design

Armor protects the cable from mechanical damage in demanding installations. -

Extreme Temperature Capability

Operates between -51 °C to +177 °C at probe tip. -

High Vibration Tolerance

Handles 10 g at 10–2000 Hz. -

Certified for Hazardous Environments

CE, ATEX Zone 2, CSA, IECEx compliance. -

Maintenance-Free Operation

Factory calibrated with excellent long-term stability. -

Full Compatibility

Integrates seamlessly with 3300 XL Proximitor Sensors and Bently Nevada monitoring systems. -

Moisture-Resistant

100% humidity sealed design. -

Field-Proven Performance

Installed in thousands of critical machines worldwide. -

Backed by Industry Trust

Part of Bently Nevada’s globally trusted 3300 XL family.

Frequently Asked Questions (FAQ)

-

What is the cable length for this model?

0.5 meter, armored. -

Is it compatible with 3300 XL Proximitor Sensors?

Yes — fully compatible with 3300 XL Proximitor Sensors. -

What is the primary application of this probe?

Shaft vibration, thrust position, and dynamic movement monitoring. -

Can this model be used in hazardous environments?

Yes — it meets CE, ATEX Zone 2, CSA, and IECEx standards. -

What is its linear measurement range?

2 mm (80 mils). -

Does it need field calibration?

No — it is factory calibrated. -

What is the probe tip made from?

PPS (Polyphenylene sulfide), a high-temperature engineering polymer. -

What are typical target materials?

Calibrated for 4140 steel, widely used in rotating machinery. -

How is armored cable different from non-armored?

Armored cable provides enhanced mechanical protection. -

In which industries is this probe typically used?

Power generation, oil & gas, chemical, refining, heavy industry.

Related Models from the Same Series or Category

| Model | Product Type | Cable Length | Armor Type | Dimensions & Weight |

|---|---|---|---|---|

| 330104-01-05-05-02-00 | 3300 XL 8 mm Probe | 5 ft (1.52 m) | Armored | 8 mm tip, ~0.48 kg |

| 330104-00-10-10-01-CN | 3300 XL 8 mm Probe | 10 ft (3.05 m) | Non-armored | 8 mm tip, ~0.45 kg |

| 330104-00-15-10-01-CN | 3300 XL 8 mm Probe | 15 ft (4.57 m) | Non-armored | 8 mm tip, ~0.50 kg |

| 330104-00-20-10-02-00 | 3300 XL 8 mm Probe | 20 ft (6.10 m) | Non-armored | 8 mm tip, ~0.57 kg |

| 330104-00-25-10-02-05 | 3300 XL 8 mm Probe | 25 ft (7.62 m) | Non-armored | 8 mm tip, ~0.62 kg |

| 330104-00-25-05-02-00 | 3300 XL 8 mm Probe | 25 ft (7.62 m) | Armored | 8 mm tip, ~0.65 kg |

Popular Models from Bently Nevada Product Line

| Model | Product Type | Application Area | Dimensions & Weight |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | Machine Protection Systems | ~0.80 kg |

| 3500/42M | Proximitor/Seismic Monitor | Shaft vibration, bearing wear | ~1.20 kg |

| 3500/33 | RTD/TC Temperature Monitor | Motor winding / bearing temp | ~1.10 kg |

| 330130-040-00-00 | 3300 XL 8 mm Extension Cable | Drives matching probes | ~0.30 kg |

| 330180-50-00 | 3300 XL Proximitor Sensor | Drives 3300 XL 8 mm probes | ~0.50 kg |

| 3500/15 | Power Supply Module | 3500 Series Rack | ~1.50 kg |

Excellent PLC

Excellent PLC