| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Overview

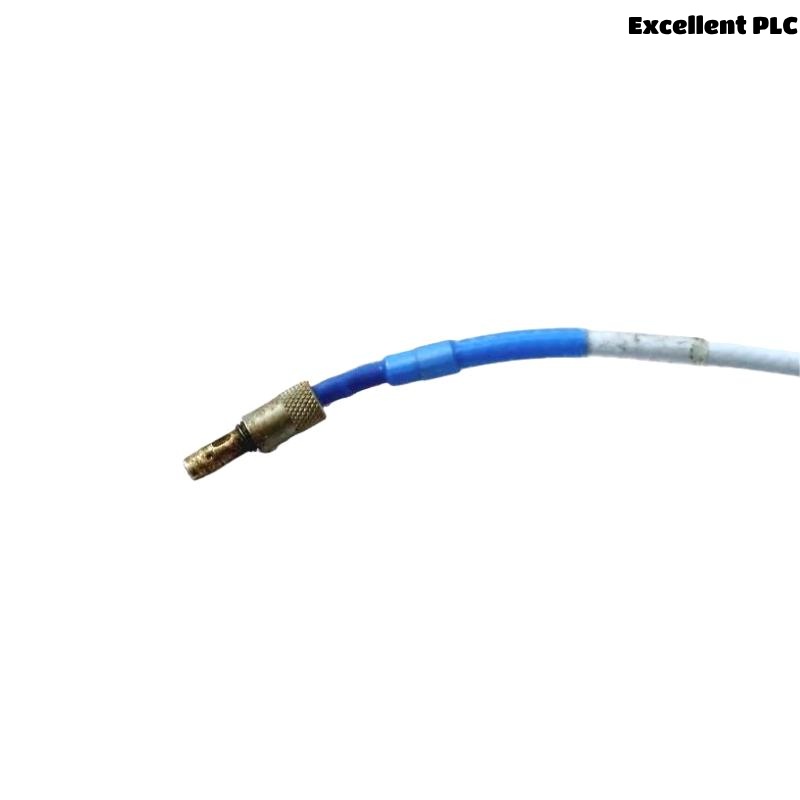

The Bently Nevada 330104-08-14-10-02-05 is a high-performance 8 mm proximity probe used in the 3300 XL series. It forms part of a non-contact transducer system designed to measure shaft position and vibration in rotating machinery. It is engineered for robust operation in industrial conditions with a flexible armored cable, M10 thread, and 1.0 meter total probe length.

Applications

-

Radial vibration and axial position measurements on fluid-film bearing machines

-

Overspeed protection and Keyphasor reference

-

Shaft displacement and rotating machinery condition monitoring

-

Used in turbines, compressors, pumps, and motors

Advantages

-

API 670 compliant performance

-

Interchangeable probes, extension cables, and sensors

-

Excellent RFI/EMI immunity

-

Corrosion-resistant ClickLoc gold connectors

-

Withstands temperatures up to 177°C (standard), 218°C (ETR option)

-

FluidLoc cable option prevents oil leakage

-

No field calibration required

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Type | 3300 XL 8 mm, M10 x 1 thread, with armor |

| Total Length | 1.0 meter |

| Weight | Approx. 0.323 kg |

| Case Material | AISI 303 or 304 stainless steel |

| Tip Material | PPS (Polyphenylene sulfide) |

| Output Sensitivity | 7.87 V/mm (200 mV/mil) ±5% |

| Linear Range | 2.0 mm (80 mils) |

| Gap Voltage (Recommended) | -9 VDC (approx. 1.27 mm or 50 mils) |

| Operating Temp (Standard Probe) | -52°C to +177°C |

| Operating Temp (ETR Probe) | -52°C to +218°C (tip), -51°C to +260°C (cable) |

| Minimum Target Size | 15.2 mm (0.6 in) diameter |

| Minimum Shaft Diameter | 50.8 mm (2 in) |

| Cable Type | Armored FEP insulated coaxial, 75 Ω |

| Connector | ClickLoc Miniature Coaxial, gold-plated |

| Installation Torque (M10) | Max: 22.6 N·m, Recommended: 7.5 N·m |

FAQs

Q1: What type of thread does the 330104-08-14-10-02-05 probe use?

A1: It uses M10 x 1 metric thread with armored cable.

Q2: Can this probe be used in high-temperature environments?

A2: Yes, standard probes support up to 177°C, and ETR versions up to 218°C (tip) or 260°C (cable).

Q3: Is this probe compatible with older 3300 systems?

A3: Yes, it’s fully interchangeable with non-XL 3300 8 mm components.

Q4: Does the probe require field calibration?

A4: No, it comes factory-calibrated and supports full component interchangeability.

Q5: What are the primary applications for this probe?

A5: Used in turbines, compressors, and motors for position and vibration monitoring.

Q6: What is the recommended probe-to-target gap setting?

A6: Approximately 1.27 mm (50 mils) resulting in -9 VDC output.

Q7: How is the cable protected from environmental damage?

A7: It features armored construction and optional connector protectors.

Q8: Can this be used for overspeed protection?

A8: Yes.

Q9: What’s the output voltage characteristic?

A9: Voltage is proportional to the distance from the probe tip to the target surface.

Q10: Does it comply with industrial standards?

A10: Yes, it meets API 670 requirements and has CE, FCC, RoHS, and SIL certifications.

Related Models in the Same Series

| Model Number | Description | Thread Type | Length | Armor | Weight |

|---|---|---|---|---|---|

| 330104-00-06-10-02-00 | 3300 XL 8 mm Probe, M10, armored | M10 | 0.6 m | Yes | ~0.300 kg |

| 330104-01-05-50-02-00 | 3300 XL 8 mm Probe, M10, armored | M10 | 5.0 m | Yes | ~0.700 kg |

| 330103-00-02-10-02-05 | 3300 XL 8 mm Probe, M10, no armor | M10 | 1.0 m | No | ~0.200 kg |

| 330101-00-08-10-02-05 | 3300 XL 8 mm Probe, 3/8-24 UNF, armored | UNF | 1.0 m | Yes | ~0.323 kg |

| 330105-02-12-10-02-00 | 3300 XL 8 mm Reverse Mount Probe, 3/8-24, no armor | UNF | 1.0 m | No | ~0.280 kg |

| 330106-05-30-10-02-05 | 3300 XL 8 mm Reverse Mount Probe, M10, armored | M10 | 3.0 m | Yes | ~0.450 kg |

Popular Models from Bently Nevada

| Model Number | Description | Application | Weight |

|---|---|---|---|

| 330104-08-14-10-02-05 | 3300 XL 8 mm Probe with armor, M10 thread | Shaft vibration/position monitoring | 0.323 kg |

| 330130-030-00-05 | 3300 XL Standard Extension Cable, 3.0 m | Cable for proximity system | 0.102 kg |

| 330180-50-05 | 3300 XL Proximitor Sensor, 5 m, panel mount | Converts signal for monitoring | 0.246 kg |

| 3500/42M-01-00 | Proximitor Seismic Monitor Module | Machinery health monitoring | 0.300 kg |

| 3300 XL NSv | Narrow Side View Proximity Probe System | Tight-space installations | ~0.250 kg |

| 3300/16 | 16-Channel Monitor System | General-purpose monitoring system | ~0.500 kg |

Excellent PLC

Excellent PLC