| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

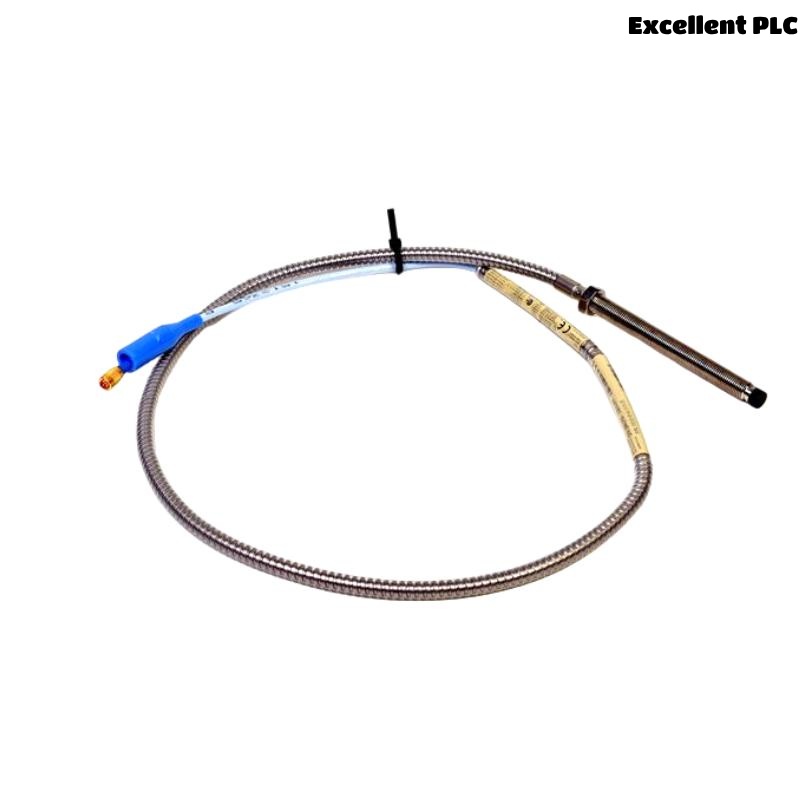

The Bently Nevada 330104-08-15-10-02 3300 XL 8mm Proximity Probe is a highly reliable and precise sensor designed for monitoring the displacement and vibration of rotating machinery shafts. This probe is part of the 3300 XL series, known globally for its robustness and accuracy in critical industrial applications. The 8mm probe tip length provides an ideal sensing range that ensures sensitive detection of shaft movement, critical for predictive maintenance and preventing unplanned downtime.

Manufactured using high-quality stainless steel and employing eddy current technology, the probe delivers consistent performance even in harsh operating conditions including extreme temperatures and vibration. Its compatibility with the Bently Nevada 3300 XL monitoring system makes it an excellent choice for industrial operators looking to maintain continuous, reliable asset monitoring.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330104-08-15-10-02 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Probe Tip Length | 8 mm |

| Probe Diameter | 12.7 mm (0.5 inches) |

| Total Length | 1 meter |

| Operating Temperature | -40°C to 120°C (-40°F to 248°F) |

| Output Signal Type | AC Voltage Signal |

| Sensing Technology | Eddy Current |

| Housing Material | Stainless Steel |

| Connector Type | 2-pin military-style connector |

| Weight | 0.323 kg |

| Shock Resistance | 100 g (11 ms half sine) |

| Vibration Resistance | 10 g (20 Hz to 2 kHz) |

Applications

The 330104-08-15-10-02 proximity probe is widely used in many industries that depend on accurate monitoring of rotating equipment, including:

-

Power Generation: Continuous monitoring of turbine shafts, generators, and motors to ensure safe operation.

-

Oil & Gas: Protecting pumps, compressors, and drilling equipment from unexpected failures.

-

Aerospace: Monitoring engine components and rotary machinery for safety and reliability.

-

Manufacturing: Used in high-speed spindles, gearboxes, and conveyor systems to detect early signs of wear.

-

Mining and Metals: Monitoring crushers, mills, and conveyor belts under demanding conditions.

-

Chemical Processing: Monitoring pumps and agitators critical to continuous production processes.

Advantages

-

High Accuracy: Uses eddy current sensing technology for precise measurement of displacement and vibration.

-

Durable Construction: Stainless steel housing ensures corrosion resistance and mechanical toughness.

-

Wide Temperature Range: Suitable for use in environments ranging from -40°C to 120°C.

-

System Compatibility: Fully compatible with Bently Nevada 3300 XL monitoring systems for seamless integration.

-

Compact and Easy to Install: Standard connectors and compact size simplify installation and maintenance.

-

Stable Signal Output: Provides consistent AC voltage signals to ensure reliable condition monitoring.

-

Shock and Vibration Resistant: Designed to endure harsh industrial mechanical stresses.

-

Custom Cable Lengths: Available to meet diverse installation requirements.

Frequently Asked Questions (FAQ)

-

What is the main use of the 330104-08-15-10-02 proximity probe?

It measures shaft displacement and vibration to help detect mechanical faults early. -

Is this probe compatible with the Bently Nevada 3300 XL system?

Yes, it is designed for full compatibility with the 3300 XL series monitoring equipment. -

What kind of output signal does the probe produce?

The probe outputs an AC voltage signal proportional to shaft displacement. -

Can I get the probe with a longer cable?

Yes, while the standard total length is 1 meter, custom lengths can be provided. -

What temperature range can the probe operate within?

It operates reliably between -40°C and 120°C. -

Does the probe require external power?

No, the probe functions without external power by using eddy current principles. -

How often should the probe be calibrated or maintained?

Regular inspections and annual calibration are recommended for optimal performance. -

Is the probe suitable for use on high-speed rotating shafts?

Yes, it is designed for high-speed shaft applications. -

What should I do if the probe cable is damaged?

The cable should be replaced promptly to maintain accurate signal transmission. -

Can this probe detect issues like shaft misalignment?

Yes, by monitoring changes in displacement and vibration, it helps identify misalignment.

Related and Recommended Models

| Related Models (3300 XL Series) | Description |

|---|---|

| 330104-08-15-10-02 | 8mm Proximity Probe (Current Model) |

| 330103-17-22-10-02-05 | 8mm Proximity Probe Alternate Model |

| 330103-15-23-05-02-CN | 8mm Proximity Probe Alternate Specification |

| 330101-00-44-10-02-05 | 8mm Proximity Probe |

| 330102-13-23-05-02-00 | 12mm Proximity Probe |

| 330130-00-00-00-10-02 | Probe Extension Cable |

| Popular Models from Bently Nevada Brand | Description |

|---|---|

| 330104-08-15-10-02 | 8mm Proximity Probe (Current Model) |

| 3500/05/01-01 | 3500 Series Monitor Module |

| 73011-00-00-10-00-00 | 3300 XL Monitor Amplifier |

| 330104-00-00-10-05-02 | 18mm Proximity Probe |

| 330101-00-44-10-02-05 | 8mm Proximity Probe |

| 330121-00-00-05-00-02 | Vibration Sensor |

Excellent PLC

Excellent PLC