| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

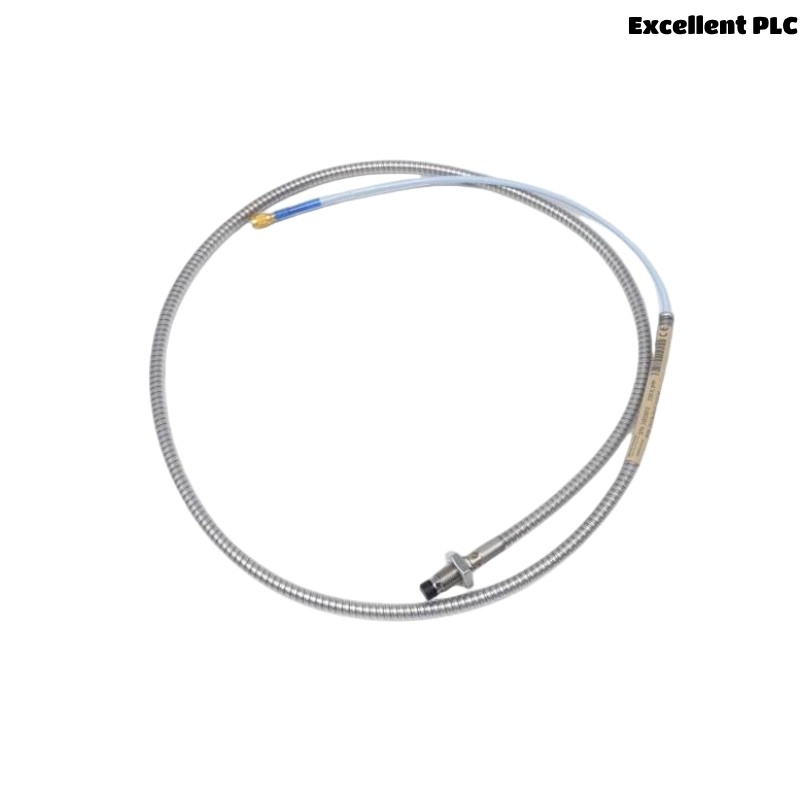

The Bently Nevada 330104-09-19-10-02-00 is part of the 3300 XL 8 mm Proximity Transducer System, a high-performance sensor solution designed for machinery condition monitoring and protection. Engineered for precision and reliability, this proximity probe is used extensively in industrial applications such as turbines, compressors, pumps, and motors to detect shaft vibration, axial position, and other dynamic measurements.

The 3300 XL 8 mm system includes the proximity probe, extension cable, and Proximitor sensor. Together, they deliver accurate non-contact displacement measurements of conductive targets, primarily rotating shafts. The model 330104-09-19-10-02-00 features a 9-meter system length and is fully API 670 compliant, ensuring compatibility with critical industrial applications.

Key Features

-

Non-contact vibration measurement for rotating machinery

-

8 mm probe tip designed for standard industrial target materials (e.g., AISI 4140 steel)

-

Rugged stainless steel construction for durability in harsh environments

-

Fully API 670 compliant for condition monitoring systems

-

Wide temperature tolerance suitable for extreme operating conditions

-

Precision calibration for accurate displacement detection

-

Shielded construction for minimal electrical interference

-

Factory matched probe and cable for guaranteed system performance

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 330104-09-19-10-02-00 |

| Series | 3300 XL 8 mm Proximity Probe |

| Sensing Principle | Eddy current |

| Probe Tip Diameter | 8 mm (0.315 in) |

| Tip Material | PPS (Polyphenylene sulfide) |

| Body Material | AISI 304 Stainless Steel |

| Thread Type | 3/8-24 UNF-2A |

| Target Material | AISI 4140 steel or equivalent |

| Sensitivity | 7.87 mV/μm (200 mV/mil) ±5% |

| Linear Range | 2 mm (80 mils) |

| Frequency Response | 0 to 10 kHz |

| Temperature Range | -35°C to +177°C (-31°F to +351°F) |

| Vibration Limit (Probe) | 50 g pk-pk @ 5-2,000 Hz |

| Weight | 0.323 kg |

| Dimensions | Total Length : 1.0 meter |

| Connector Type | Miniature coaxial |

| Compliance | API 670, CE, RoHS |

Industry Applications

The Bently Nevada 330104-09-19-10-02-00 proximity probe is widely adopted in industrial settings that demand precise, reliable machinery monitoring and protection. It is ideal for:

-

Steam and gas turbines

-

Compressors (centrifugal, axial, reciprocating)

-

Industrial pumps and blowers

-

Motors and generators

-

Gearboxes and gear-driven systems

-

Machine train alignment verification

-

Axial thrust position detection

-

Shaft radial vibration monitoring

Product Advantages

-

Highly reliable: Trusted by leading industries for over three decades with proven long-term stability

-

Excellent linearity and sensitivity: Ensures accurate readings across the linear range, supporting predictive maintenance

-

Durable and corrosion-resistant: Stainless steel construction ensures performance in corrosive and high-vibration environments

-

Easy installation and interchangeability: Probe and cable assemblies are matched at the factory, minimizing field calibration effort

-

Extended operating range: Withstands elevated temperatures, making it suitable for demanding applications like gas turbines

-

API 670 compliance: Ensures compatibility with standard machine protection systems

-

Enhanced EMI/RFI shielding: Ensures performance in electrically noisy environments

-

Modular system: Compatible with all 3300 XL extension cables and Proximitor sensors

Frequently Asked Questions (FAQ)

-

What is the function of the 330104-09-19-10-02-00 probe?

It measures the non-contact displacement of a conductive target, such as a rotating shaft, for machinery monitoring and protection. -

What is the difference between this model and other 3300 XL probes?

The main difference lies in the system length, tip configuration, and mounting thread specifications. -

Is the probe compatible with other Bently Nevada systems?

Yes, it is compatible with 3300 XL Proximitor sensors and extension cables when used as part of a matched set. -

Can this probe be used in high-temperature environments?

Yes, it supports operation up to 177°C (351°F), suitable for high-performance turbines and similar equipment. -

What is the accuracy of this probe?

It provides ±5% accuracy at 7.87 mV/μm sensitivity, delivering highly reliable data. -

Does this probe comply with API 670?

Yes, the 3300 XL series, including this model, meets API 670 standards for critical machinery protection. -

Is the probe resistant to oil and harsh industrial conditions?

Yes, its PPS tip and stainless-steel body offer resistance to oil, chemicals, and vibration. -

What target materials is it compatible with?

It is factory-calibrated for AISI 4140 steel but can be adapted for other conductive materials if required. -

Is calibration necessary in the field?

No, when used with factory-matched cables and Proximitor sensors, no field calibration is needed. -

What is the recommended mounting torque for this probe?

28 to 34 in·lb (3.2 to 3.8 N·m) is the standard mounting torque for secure installation.

Related Models

| Model Number | Description |

|---|---|

| 330104-00-05-10-02-00 | 8 mm probe, 0.5 in thread, 5 m system |

| 330104-00-12-10-02-05 | 8 mm probe, 1.2 in thread, 5 m system, armored |

| 330104-00-07-10-02-00 | 8 mm probe, 0.7 in thread, 5 m system |

| 330104-00-18-10-02-05 | 8 mm probe, 1.8 in thread, 5 m system, armored |

| 330104-01-08-50-01-CN | 8 mm probe, 8 m system, 50 Ω connector, China version |

| 330104-04-10-05-01-05 | 8 mm probe, 10 in length, 5 m system, armored |

Popular Models

| Model Number | Description |

|---|---|

| 330101-00-14-10-02-05 | 3300 XL 8 mm Proximity Probe, 14 ft, standard version |

| 330130-045-00-00 | 3300 XL Extension Cable, 45 ft |

| 330180-91-05 | 3300 XL Proximitor Sensor, 5 m system |

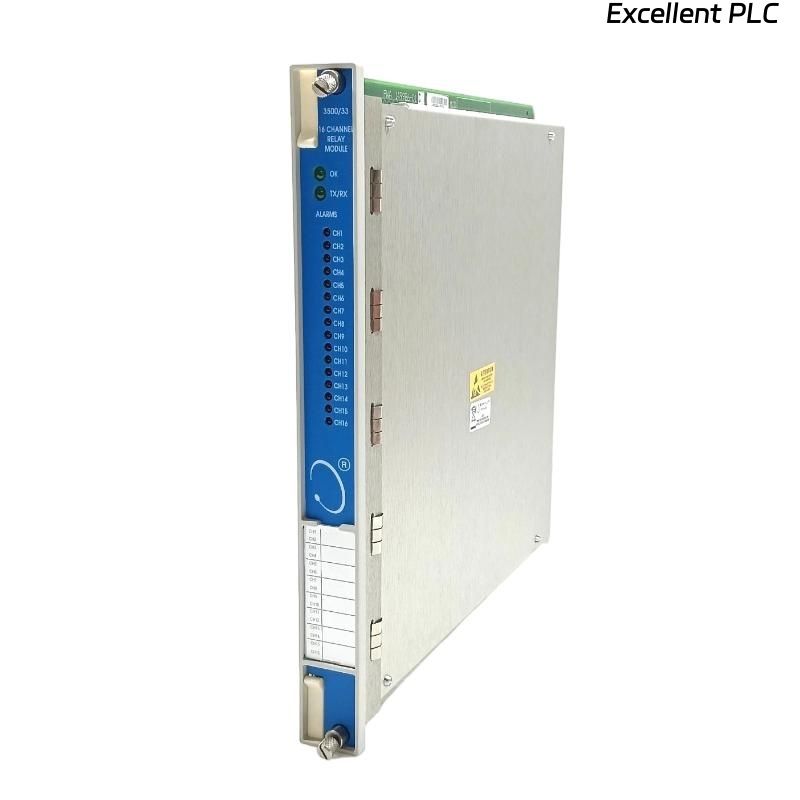

| 3500/22M-01-01-00 | 3500/22M Transient Data Interface Module |

| 3500/42M-01-00 | 3500/42M Proximitor Monitor |

| 144181-01 | Velocity Transducer, used for casing vibration measurement |

Excellent PLC

Excellent PLC