| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

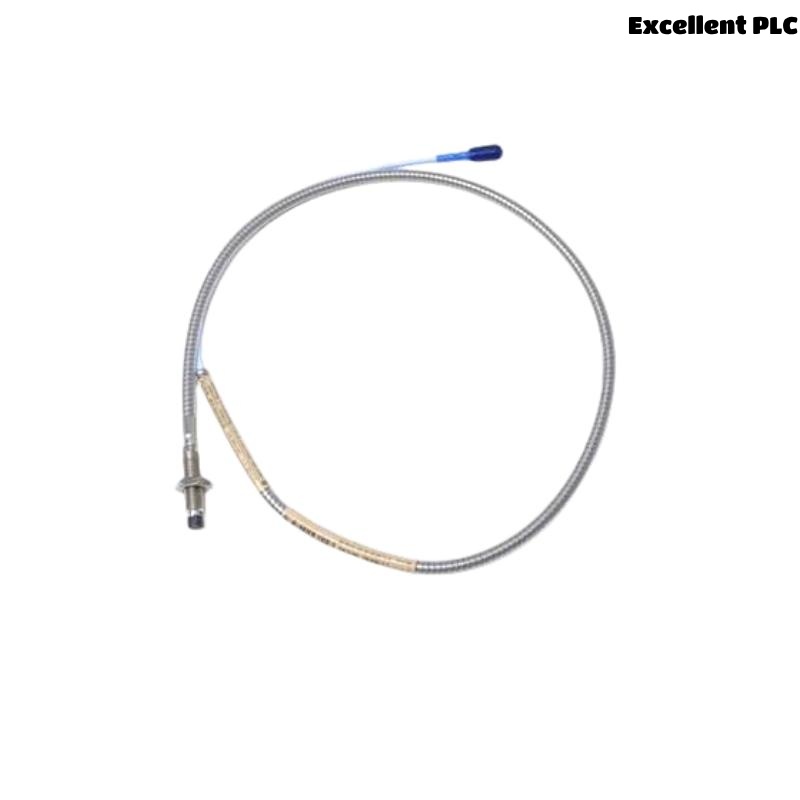

The Bently Nevada 330104-15-23-50-02-00 is an 8 mm proximity probe from the 3300 XL series, renowned for its high performance, precision, and reliability in monitoring machinery health. The 3300 XL proximity probes are widely used across industries that require accurate vibration and position measurements for rotating machinery. This sensor offers a robust solution for proactive machinery condition monitoring, detecting early signs of wear, imbalance, misalignment, and other mechanical issues that could lead to costly downtime.

Designed for use in demanding industrial environments, the 3300 XL 8 mm probe provides real-time feedback and highly accurate measurements, helping operators identify potential failures before they occur. The 3300 XL series, including this model, is ideal for use in power generation, oil & gas, mining, and manufacturing industries, where maintaining operational efficiency and machinery reliability is critical.

Product Parameters

The following table outlines the key specifications of the Bently Nevada 330104-15-23-50-02-00 3300 XL 8 mm proximity probe:

| Parameter | Value |

|---|---|

| Model | 330104-15-23-50-02-00 |

| Total Length | 5.0 meters |

| Weight | 1.615 kg |

| Sensing Range | 8 mm |

| Measurement Type | Proximity/Vibration Sensor |

| Operating Temperature | -40°C to +85°C |

| Mounting Style | Threaded/Stud Mount |

| Material | Stainless Steel |

| Voltage Rating | 24V DC |

| Output | 4-20 mA |

| Application | Vibration Monitoring, Machinery Health Monitoring |

Product Applications

The Bently Nevada 330104-15-23-50-02-00 3300 XL 8 mm proximity probe is versatile and widely applicable across several industries where machinery monitoring is crucial. The following are key applications for this probe:

-

Turbine Monitoring: In power generation plants, turbines need continuous monitoring for vibrations to avoid failures and ensure optimal performance. The 3300 XL probe provides precise readings, enabling operators to detect problems like misalignment or unbalanced components.

-

Compressor Monitoring: Compressors in industries such as petrochemical or HVAC systems need to be constantly checked for wear and vibrations that could indicate potential failure. This proximity probe is essential for maintaining efficient and safe operation.

-

Pump Monitoring: Pumps used in industries like water treatment, oil & gas, and chemical processing can benefit from real-time vibration analysis. This probe helps detect issues like misalignment or bearing failure, which could disrupt operations and lead to costly repairs.

-

Motor Monitoring: Industrial motors, often working under heavy loads and high stress, require continuous monitoring. The 3300 XL proximity probe offers critical data on motor health, enabling early intervention before a failure occurs.

-

Rotating Equipment Monitoring: Any rotating machinery, such as fans, gearboxes, or conveyors, can benefit from the 3300 XL probe. By continuously monitoring vibrations and position, this probe ensures these machines run smoothly and efficiently.

In all these applications, the 3300 XL probe helps to avoid unexpected breakdowns and extend the lifespan of machinery, leading to better operational efficiency and reduced maintenance costs.

Product Advantages

The Bently Nevada 330104-15-23-50-02-00 3300 XL 8 mm proximity probe offers several advantages, making it an ideal choice for condition monitoring in industrial environments:

-

High Precision: The 8 mm sensing range of the probe ensures accurate and reliable measurements of machinery vibrations and position, even in complex applications.

-

Long Length: With a total length of 5.0 meters, this probe can be used in a variety of installations, providing flexibility in measuring distances from machinery to sensors without losing accuracy.

-

Durability: Made from high-grade stainless steel, the 3300 XL probe is built to last and withstand harsh industrial environments, ensuring long-term performance with minimal maintenance.

-

Wide Operating Temperature Range: The probe operates within a broad temperature range of -40°C to +85°C, making it suitable for a variety of environments, including extreme heat or cold.

-

Versatile Output: The 4-20 mA output is standard for industrial monitoring systems, making integration into existing equipment and systems simple and effective.

-

Easy Installation: The 3300 XL 8 mm probe is designed with a threaded or stud mount for easy and secure installation on rotating machinery, reducing downtime and setup time.

-

Proactive Maintenance: By detecting early signs of wear, misalignment, or imbalance, this probe allows for proactive maintenance, preventing costly unscheduled downtimes and extending machinery life.

Frequently Asked Questions (FAQ)

-

What is the purpose of the Bently Nevada 3300 XL 8 mm proximity probe?

-

This probe is used for monitoring the vibration and position of rotating machinery, providing accurate measurements that help detect potential mechanical issues before they lead to failures.

-

-

What is the length of the Bently Nevada 330104-15-23-50-02-00 probe?

-

The total length of the probe is 5.0 meters, providing flexibility for various installations.

-

-

How much does the 3300 XL 8 mm proximity probe weigh?

-

The probe weighs 1.615 kg.

-

-

What is the sensing range of the Bently Nevada 3300 XL 8 mm proximity probe?

-

The sensing range is 8 mm, ideal for vibration and position monitoring.

-

-

What is the operating temperature range for the 3300 XL probe?

-

The probe operates in temperatures ranging from -40°C to +85°C, making it suitable for use in diverse environments.

-

-

How is the 3300 XL 8 mm proximity probe mounted?

-

It can be mounted using a threaded or stud mount, ensuring a secure and reliable installation.

-

-

What output does the Bently Nevada 3300 XL 8 mm probe provide?

-

The probe provides a 4-20 mA output, which is compatible with most industrial monitoring systems.

-

-

In what industries is the 3300 XL 8 mm probe used?

-

The probe is used in power generation, oil & gas, manufacturing, mining, and other industries where machinery health monitoring is essential.

-

-

How does the probe improve machinery reliability?

-

By continuously monitoring vibrations and positional shifts, the probe detects issues early, allowing for timely intervention and reducing the risk of unexpected machinery failures.

-

-

Can the 3300 XL proximity probe detect small mechanical issues?

-

Yes, the 8 mm sensing range is designed to detect even minor vibrations and shifts, making it ideal for early detection of misalignment, imbalance, and other small issues that could lead to bigger problems.

-

Related Models from the 3300 XL Series

| Model | Description |

|---|---|

| 330104-10-20-10-02-05 | Advanced control system for large-scale industrial operations |

| 330104-10-20-10-02-CN | Specialized module for automation in Chinese industrial sectors |

| 330104-10-20-10-02-06 | Modular control unit for energy-efficient manufacturing |

| 330104-10-20-10-02-07 | High-performance system for automated process optimization |

| 330104-10-20-10-02-08 | Flexible unit for power management and industrial automation |

| 330104-10-20-10-02-09 | Robust controller for real-time process monitoring in factories |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330104-10-23-50-02-00 | High-performance control unit for large-scale industrial systems |

| 330104-12-17-10-01-05 | Modular controller for real-time industrial process monitoring |

| 330104-10-23-50-02-01 | Specialized unit for energy-efficient manufacturing operations |

| 330104-12-17-10-01-06 | Flexible control module for automated production environments |

| 330104-10-23-50-02-02 | Robust system designed for optimized process control in factories |

| 330104-12-17-10-01-07 | Advanced control unit for power and energy management systems |

Excellent PLC

Excellent PLC