| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

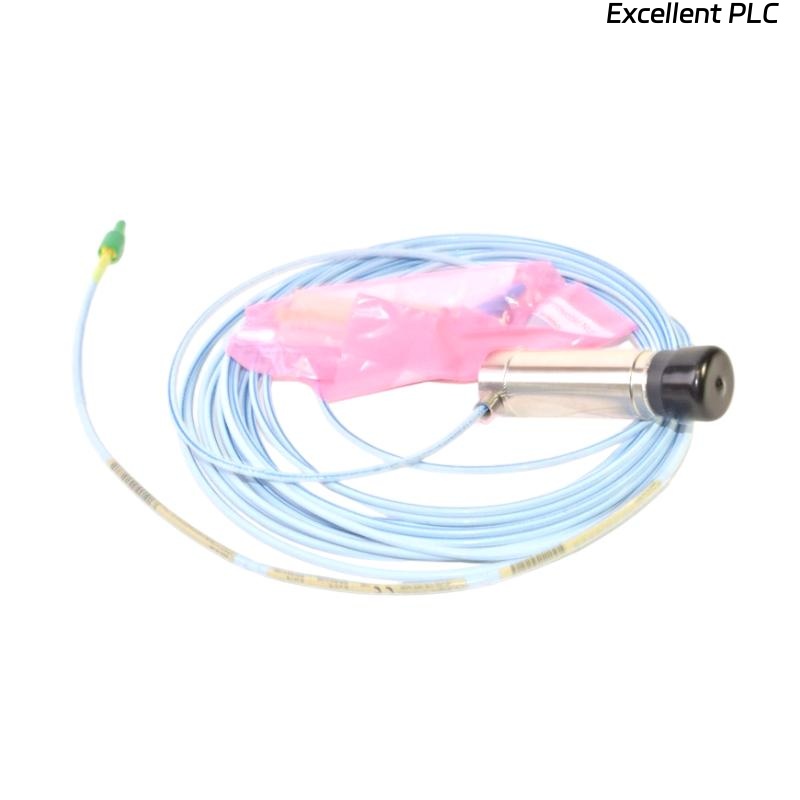

The Bently Nevada 330105-02-02-10-02-00 3300 XL 8 mm Reverse Mount Probe is a high-precision, non-contact sensor designed for shaft displacement measurement in applications where space constraints require a reverse mounting configuration. It provides accurate, real-time data for machinery monitoring, protection, and predictive maintenance, ensuring safe and reliable operation of turbines, compressors, pumps, and motors.

Key Features

-

8 mm eddy-current non-contact measurement

-

Reverse mount configuration for space-limited installations

-

High-precision shaft displacement detection

-

Compatible with 3300 XL monitoring systems

-

Resistant to oil, dust, and industrial contaminants

-

Robust and compact design for easy installation

-

Supports predictive maintenance and trend monitoring

Technical Specifications

| Item | Specification |

|---|---|

| Manufacturer | Bently Nevada |

| Part Number | 330105-02-02-10-02-00 |

| Product Type | 3300 XL 8 mm Reverse Mount Probe |

| Dimensions | Total Length : 1.0 meter |

| Weight | 0.323 kg |

| Sensing Range | 0–1.27 mm (0–50 mil) |

| Linearity | ±1% of full scale |

| Frequency Response | DC to 10 kHz |

| Operating Temperature | –20 °C to +125 °C |

| Storage Temperature | –40 °C to +150 °C |

| Humidity | 0–95% RH, non-condensing |

| Mounting | Reverse mount on bearing housing or shaft collar |

| Applications | Shaft displacement, vibration monitoring, predictive maintenance |

Industry Applications

-

Steam and gas turbines

-

Industrial pumps and motors

-

Compressors and blowers

-

Gearboxes and heavy-duty rotating machinery

-

Oil, gas, and power generation sectors

-

Condition monitoring and machinery protection

Frequently Asked Questions (FAQ)

Q1: What is the main function of the 330105-02-02-10-02-00 probe?

It measures shaft displacement for machinery monitoring and protection.

Q2: What is the sensing range of the probe?

The typical sensing range is 0–1.27 mm (0–50 mil).

Q3: Can it be installed on existing machinery?

Yes, it can be reverse mounted on bearing housings or with shaft collars.

Q4: What is the operating temperature range?

The probe operates between –20 °C and +125 °C.

Q5: Is it resistant to industrial contaminants?

Yes, it is designed to withstand oil, dust, and other harsh conditions.

Q6: What type of output signal does it provide?

It provides analog displacement signals compatible with 3300 XL monitoring systems.

Q7: Which industries commonly use this probe?

It is widely used in turbines, compressors, pumps, motors, and other rotating machinery.

Q8: Is it suitable for predictive maintenance applications?

Yes, it supports continuous condition monitoring and trend analysis.

Related Bently Nevada Modules

| Model | Description |

|---|---|

| 330104-05-10-10-01-05 | 3300 XL 8 mm Proximity Probe |

| 330104-05-13-10-02-05 | 3300 XL 8 mm Proximity Probe |

| 330104-10-23-10-01-00 | 3300 XL 8 mm Proximity Probe |

| 330105-02-02-10-02-05 | 3300 XL 8 mm Reverse Mount Probe |

| 330105-02-05-10-02-00 | 3300 XL 8 mm Reverse Mount Probe |

| 330130-045-01-05 | 3300 XL Extension Cord |

Popular Bently Nevada Modules

| Model | Description |

|---|---|

| 330105-02-02-10-02-00 | 3300 XL 8 mm Reverse Mount Probe |

| 330104-05-10-10-01-05 | 3300 XL 8 mm Proximity Probe |

| 330104-05-13-10-02-05 | 3300 XL 8 mm Proximity Probe |

| 330104-10-23-10-01-00 | 3300 XL 8 mm Proximity Probe |

| 330105-02-02-10-02-05 | 3300 XL 8 mm Reverse Mount Probe |

| 330105-02-05-10-02-00 | 3300 XL 8 mm Reverse Mount Probe |

Excellent PLC

Excellent PLC