| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

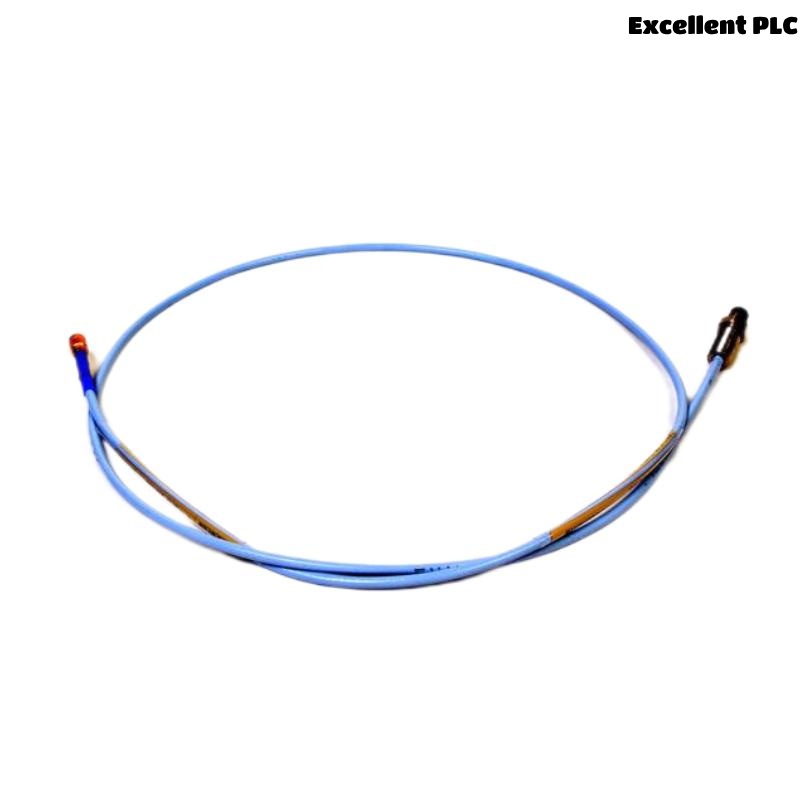

The Bently Nevada 330105-02-12-10-12-00 3300 XL 8mm Reverse Mounting Probe is a high-performance vibration sensor designed for use in demanding industrial environments. Part of the Bently Nevada 3300 XL series, this probe is engineered to provide precise and reliable vibration measurements in applications such as turbine monitoring, compressor vibration analysis, and other machinery condition monitoring systems.

With its 8mm diameter and robust construction, the 3300 XL probe is built to deliver accurate readings even in harsh operating conditions, ensuring the safety and performance of critical machinery. The reverse mounting design allows for flexible installation options, which are particularly beneficial in confined or challenging spaces where traditional mounting methods might be difficult.

This probe is widely recognized for its ease of integration with Bently Nevada’s monitoring systems and its durability, making it a trusted choice for industries such as oil and gas, energy production, manufacturing, and other sectors requiring continuous machinery health monitoring.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 330105-02-12-10-12-00 |

| Type | 3300 XL 8mm Reverse Mounting Probe |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Diameter | 8 mm |

| Material | Stainless steel and high-quality insulating materials |

| Mounting Type | Reverse mounting |

| Temperature Range | -40°C to +85°C |

| Frequency Range | 0.1 to 10,000 Hz |

| Vibration Sensitivity | High sensitivity for accurate readings |

| Application Compatibility | Compatible with Bently Nevada 3300 XL monitoring systems |

| Certifications | CE, UL, RoHS compliant |

| Protection Class | IP67 (dustproof and waterproof) |

Product Applications

The Bently Nevada 330105-02-12-10-12-00 3300 XL 8mm Reverse Mounting Probe is widely used across various industries for its precision and versatility in vibration monitoring. Some of the key applications include:

-

Turbine Vibration Monitoring: Essential for continuous monitoring of turbines in power plants, ensuring that any deviations in vibration are detected early, thus preventing equipment failure.

-

Compressor Condition Monitoring: Used in compressors to track vibrations, enabling predictive maintenance and avoiding costly downtime.

-

Pump Vibration Monitoring: The probe is used to monitor pumps in industrial systems, helping to detect imbalances or misalignments early.

-

Rotating Machinery: Suitable for monitoring rotating machinery in sectors like petrochemical, manufacturing, and aerospace, providing accurate readings for condition-based maintenance.

-

Motor Monitoring: Integrated into motor systems for real-time vibration feedback, enhancing maintenance strategies and improving operational efficiency.

-

Centrifugal Machines: Used in centrifugal machines to detect unusual vibrations, indicating potential mechanical problems or system imbalances.

-

Industrial Manufacturing: In manufacturing facilities, the probe ensures machine health and uptime by providing continuous vibration data to the central control system.

Product Advantages

-

Reverse Mounting Design: The reverse mounting feature allows for easy installation even in confined or challenging spaces, making it ideal for complex machinery setups.

-

Precision Vibration Measurement: The 8mm diameter probe offers high accuracy and sensitivity, ensuring precise measurements even in high-vibration environments.

-

Durability: Made with stainless steel and rugged materials, the probe is built to withstand harsh industrial conditions, including extreme temperatures, moisture, and dust.

-

Long Measurement Range: With a frequency range from 0.1 to 10,000 Hz, the probe is highly versatile, capable of measuring low and high-frequency vibrations in a variety of machinery.

-

Wide Temperature Range: The -40°C to +85°C temperature tolerance ensures reliable operation even in extreme environmental conditions, making the probe suitable for a wide range of industries and applications.

-

Compact Design: With a total length of 1.0 meter and a weight of just 0.323 kg, the probe’s compact size and lightweight nature make it easy to install without adding unnecessary bulk to the monitoring system.

-

High Sensitivity: The high sensitivity of the probe allows for the detection of minute vibrations, helping to identify early signs of wear, misalignment, or imbalance in machinery.

-

Seamless Integration with Bently Nevada Systems: The probe is fully compatible with Bently Nevada’s 3300 XL monitoring systems, ensuring smooth integration and easy system setup.

-

IP67 Rating: The probe’s IP67 rating ensures it is dustproof and waterproof, providing reliable operation in harsh industrial environments.

-

Cost-Effective Maintenance Tool: By enabling predictive maintenance, the 3300 XL probe reduces unexpected downtime and maintenance costs, improving overall equipment reliability.

Frequently Asked Questions (FAQ)

-

What is the purpose of the Bently Nevada 330105-02-12-10-12-00 3300 XL probe?

The 3300 XL 8mm Reverse Mounting Probe is used for vibration monitoring in industrial machinery, ensuring early detection of faults such as misalignment or imbalance. -

What is the total length of the probe?

The probe has a total length of 1.0 meter. -

What is the weight of the Bently Nevada 330105-02-12-10-12-00 probe?

The probe weighs 0.323 kg. -

What is the temperature range for the probe?

The probe can operate in temperatures ranging from -40°C to +85°C. -

What is the frequency range of this probe?

The probe has a frequency range of 0.1 to 10,000 Hz, making it suitable for both low and high-frequency vibration monitoring. -

What types of machinery can this probe monitor?

It can monitor turbines, compressors, pumps, motors, centrifugal machines, and other rotating machinery. -

How is the probe mounted?

The 3300 XL probe features a reverse mounting design, which allows for easy installation even in constrained or hard-to-reach spaces. -

Is this probe compatible with other Bently Nevada monitoring systems?

Yes, the probe is fully compatible with the Bently Nevada 3300 XL monitoring systems, ensuring smooth integration. -

What certifications does the probe have?

The 3300 XL probe is CE, UL, and RoHS certified, ensuring compliance with international safety and environmental standards. -

What is the protection rating of the probe?

The probe is rated IP67, meaning it is dustproof and waterproof, providing reliable performance even in harsh environments.

Recommended Related Models (Same Series or Related)

| Model | Description | Notes |

|---|---|---|

| 330105-02-12-10-12-01 | 3300 XL 8mm Reverse Mounting Probe | Slight variation in design and application |

| 330104-02-12-10-12-00 | 3300 XL 4mm Reverse Mounting Probe | Smaller diameter for tighter spaces |

| 330106-02-12-10-12-00 | 3300 XL 8mm Standard Mounting Probe | Standard mounting for traditional setups |

| 330107-02-12-10-12-00 | 3300 XL 5mm Reverse Mounting Probe | Compact option for space-constrained areas |

| 330110-02-12-10-12-00 | 3300 XL 10mm Reverse Mounting Probe | Larger diameter for higher vibration levels |

| 330108-02-12-10-12-00 | 3300 XL 8mm Axial Mounting Probe | Axial mounting for specific applications |

Popular Bently Nevada Models (Same Brand)

| Model | Module Type | Description |

|---|---|---|

| 3300/05 | Vibration Transducer | Used for measuring machinery vibrations |

| 3300/06 | Vibration Probe | Vibration sensor for general machinery use |

| 3300/10 | Proximity Probe | Measures displacement and proximity of rotating machinery |

| 3300/11 | Vibration Monitor | Monitors vibration and provides predictive maintenance data |

| 3500/42 | Machinery Protection System | Advanced protection system for rotating machinery |

| 3500/72 | Vibration Monitor | Monitors vibration, temperature, and other parameters for machinery protection |

Excellent PLC

Excellent PLC