| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

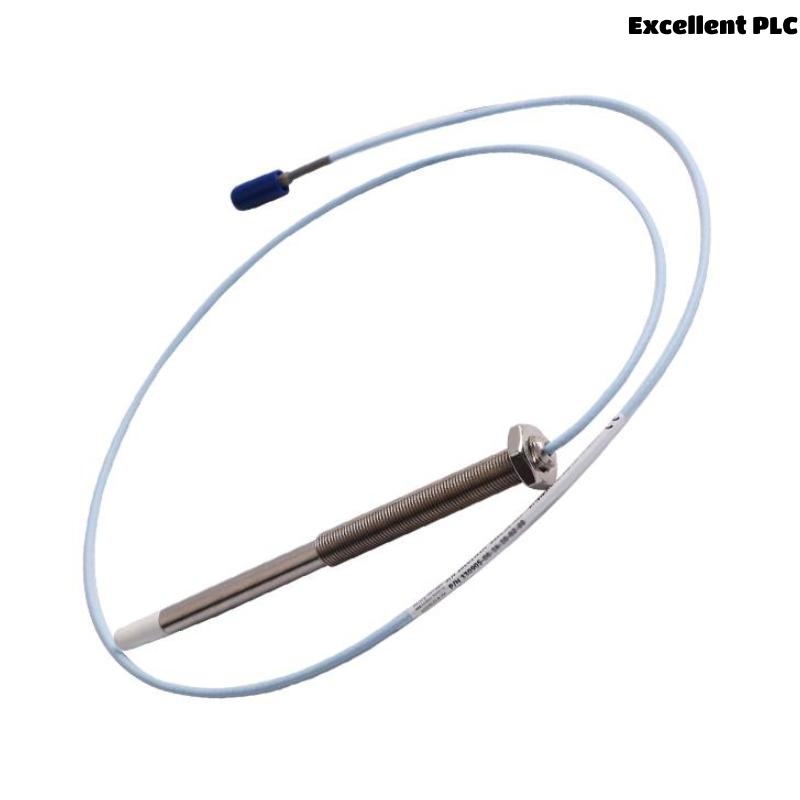

The Bently Nevada 330105-02-12-15-12-05 3300 XL 8mm Reverse Mounting Probe is a high-precision vibration sensor designed for critical monitoring applications in industrial machinery. As part of the Bently Nevada 3300 XL series, it offers outstanding performance in a variety of harsh industrial environments, including power plants, oil rigs, and manufacturing facilities.

This probe provides a unique reverse mounting design, making it ideal for installations where traditional mounting options may be impractical. With its 8mm diameter and 1.5-meter total length, this sensor is highly versatile and suitable for a wide range of machinery, including turbines, compressors, and pumps.

The 3300 XL 8mm Reverse Mounting Probe is designed to deliver accurate and reliable vibration measurements, even in extreme conditions. It is compatible with Bently Nevada’s 3300 XL monitoring systems, enabling seamless integration into advanced machinery health management solutions.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 330105-02-12-15-12-05 |

| Type | 3300 XL 8mm Reverse Mounting Probe |

| Total Length | 1.5 meter |

| Weight | 0.485 kg |

| Diameter | 8 mm |

| Material | Stainless steel, durable insulating materials |

| Mounting Type | Reverse mounting |

| Temperature Range | -40°C to +85°C |

| Frequency Range | 0.1 to 10,000 Hz |

| Vibration Sensitivity | High sensitivity for accurate readings |

| Application Compatibility | Compatible with Bently Nevada 3300 XL monitoring systems |

| Certifications | CE, UL, RoHS compliant |

| Protection Class | IP67 (dustproof and waterproof) |

Product Applications

The Bently Nevada 330105-02-12-15-12-05 3300 XL 8mm Reverse Mounting Probe is designed for vibration monitoring in industrial machinery, especially in applications where high reliability and accuracy are crucial. Some of the key applications include:

-

Turbine Vibration Monitoring: The probe is commonly used in turbines for real-time vibration monitoring, helping prevent catastrophic failures by detecting misalignments and imbalances early.

-

Compressor Monitoring: It provides continuous vibration data for compressors in industrial environments, enabling predictive maintenance to optimize performance and avoid downtime.

-

Pump Condition Monitoring: In water treatment plants and manufacturing facilities, this probe helps monitor pump health by detecting any unusual vibrations indicative of mechanical failure.

-

Rotating Machinery: Widely used in rotating machinery, the probe offers precise vibration readings that aid in identifying faults and improving maintenance strategies.

-

Motor Vibration Monitoring: The probe is an excellent choice for motor systems, helping monitor vibrations that can indicate wear, imbalance, or misalignment.

-

Centrifugal Machines: It is ideal for use in centrifugal machines, providing early warning of mechanical issues that could lead to downtime.

-

Manufacturing Equipment: In manufacturing settings, the 3300 XL probe ensures the reliable operation of machinery, facilitating continuous monitoring to reduce the risk of unplanned outages.

-

Automated Industrial Systems: The probe can be integrated into automated systems to monitor the vibration levels of critical equipment, providing early alerts for preventive maintenance.

Product Advantages

-

Reverse Mounting Design: The reverse mounting feature provides flexibility for installations in tight spaces, making it easier to use in complex machinery setups.

-

High Sensitivity: With 8mm diameter and excellent vibration sensitivity, this probe provides precise readings of even the smallest changes in vibration.

-

Durable Construction: Built with stainless steel and durable insulating materials, the probe is designed to withstand the most demanding industrial conditions, including temperature extremes, moisture, and harsh vibrations.

-

Wide Frequency Range: The 0.1 to 10,000 Hz frequency range makes it suitable for a broad array of vibration monitoring applications, from low to high-frequency detection.

-

Longer Length Option: With a total length of 1.5 meters, the probe allows for more flexible installations and can be adapted to various machine configurations.

-

Wide Temperature Range: The probe operates reliably in environments ranging from -40°C to +85°C, making it suitable for both cold and hot industrial environments.

-

IP67 Rating: With an IP67 rating, the probe is dustproof and waterproof, ensuring consistent operation in challenging environments.

-

Compatibility with Bently Nevada Systems: The probe is designed for seamless integration with Bently Nevada’s 3300 XL monitoring systems, ensuring reliable data collection and analysis.

-

Compact and Lightweight: Despite its robust construction, the probe is compact and lightweight, with a weight of 0.485 kg, making it easy to handle and install.

-

Improved Maintenance Planning: By providing accurate vibration data, this probe helps implement predictive maintenance, reducing downtime and maintenance costs.

Frequently Asked Questions (FAQ)

-

What is the purpose of the Bently Nevada 330105-02-12-15-12-05 3300 XL probe?

The probe is used to monitor the vibration levels of industrial machinery, providing real-time data for predictive maintenance and fault detection. -

What is the total length of this probe?

The total length of the 3300 XL probe is 1.5 meters. -

What is the weight of the probe?

The probe weighs 0.485 kg, making it lightweight and easy to handle during installation. -

What is the temperature range for the Bently Nevada 330105-02-12-15-12-05 probe?

The probe operates in a temperature range from -40°C to +85°C. -

What is the frequency range of the 3300 XL 8mm Reverse Mounting Probe?

The frequency range is 0.1 to 10,000 Hz, allowing it to detect both low and high-frequency vibrations. -

How is the probe mounted?

The probe features a reverse mounting design, which enables flexible installation in tight or challenging spaces. -

What types of machinery can this probe be used on?

It is suitable for use on turbines, compressors, pumps, motors, centrifugal machines, and other rotating equipment. -

Is the 3300 XL 8mm Reverse Mounting Probe compatible with other Bently Nevada systems?

Yes, it is fully compatible with Bently Nevada’s 3300 XL monitoring systems. -

What certifications does the probe have?

The probe is CE, UL, and RoHS compliant, ensuring it meets international safety and environmental standards. -

What protection rating does the 3300 XL probe have?

The probe is rated IP67, meaning it is dustproof and waterproof, providing reliable performance in harsh industrial environments.

Recommended Related Models (Same Series or Related)

| Model | Description | Notes |

|---|---|---|

| 330105-02-12-15-12-00 | 3300 XL 8mm Reverse Mounting Probe | Same design with slightly different length |

| 330104-02-12-15-12-05 | 3300 XL 4mm Reverse Mounting Probe | Smaller diameter for tighter spaces |

| 330106-02-12-15-12-00 | 3300 XL 10mm Reverse Mounting Probe | Larger diameter for high-vibration systems |

| 330103-02-12-15-12-05 | 3300 XL 5mm Reverse Mounting Probe | Compact probe for smaller applications |

| 330109-02-12-15-12-05 | 3300 XL 8mm Standard Mounting Probe | Standard mounting for conventional installations |

| 330110-02-12-15-12-00 | 3300 XL 8mm Axial Mounting Probe | Axial mounting for specific applications |

Popular Bently Nevada Models (Same Brand)

| Model | Features | Application Areas |

|---|---|---|

| 330106-05-30-05-02-00 | Multi-channel I/O, high accuracy | Industrial automation, data acquisition |

| 330106-05-30-05-02-05 | Enhanced connectivity, robust design | Control systems, machine monitoring |

| 330106-05-30-05-02-BR | Isolated I/O, high reliability | Process control, instrumentation |

| 330106-05-30-05-03-00 | High-speed signal processing | PLC systems, real-time monitoring |

| 330106-05-30-05-03-05 | Multi-input/output, flexible configuration | Distributed control, smart devices |

| 330106-05-30-05-03-BR | Low power consumption, extended range | Robotics, automated control |

Excellent PLC

Excellent PLC