| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

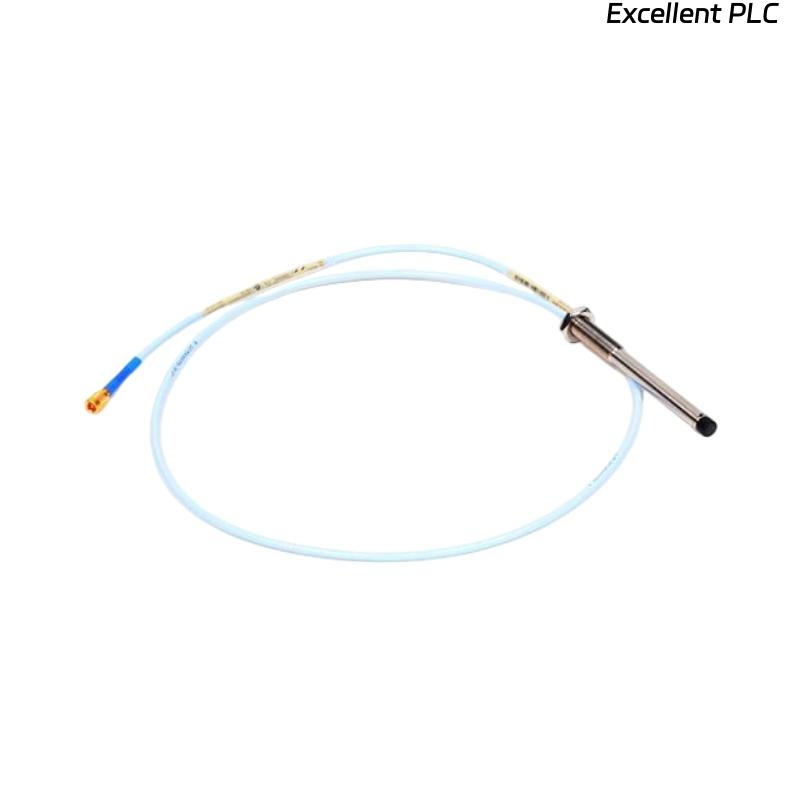

The Bently Nevada 330105-02-15-05-02-02 is a part of the highly reliable 3300 XL series, designed to provide high-precision vibration measurements for machinery condition monitoring. This 8mm reverse-mounted probe is engineered specifically for applications where space is limited or installation is challenging. The reverse-mounting capability allows it to be installed in hard-to-reach places, providing a flexible solution for machinery protection. The probe works seamlessly with Bently Nevada’s 3300 XL vibration monitoring system, delivering real-time data for predictive maintenance, helping to prevent costly failures.

This probe is ideal for industries such as power generation, oil & gas, manufacturing, and any field where rotational machinery needs constant monitoring to prevent catastrophic failures due to vibration. Its durability and precision make it a reliable tool in challenging environments, delivering actionable insights that contribute to effective predictive maintenance strategies.

Key Features

-

Reverse Mounting: The probe’s reverse-mount design makes it adaptable to tight spaces and difficult-to-access installation points.

-

Precision Measurement: Offers high accuracy in vibration monitoring, essential for detecting early signs of mechanical failure.

-

Seamless Integration: Fully compatible with the 3300 XL system, providing enhanced diagnostics and integrated performance.

-

Durability: Built to withstand harsh industrial conditions, the probe provides continuous, reliable performance.

-

Flexible Use: Suitable for a wide range of machinery, from pumps to turbines, across various industrial sectors.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 330105-02-15-05-02-02 |

| Probe Type | Reverse-Mounted 8mm Vibration Probe |

| Total Length | 0.5 meter |

| Weight | 0.162 kg |

| Measurement Range | 0 – 1000 Hz (ideal for rotating machinery) |

| Signal Output | 4-20mA or compatible with 3300 XL monitoring systems |

| Operating Temperature Range | -40°C to 85°C |

| Frequency Response | Broad range suitable for industrial machinery applications |

| Probe Diameter | 8mm |

| Vibration Measurement Type | Vibration in rotating machinery |

| Installation Type | Reverse mounting for versatility in installation |

| Protection Class | Designed for industrial environments with IP65 rating (environment dependent) |

Applications

The Bently Nevada 330105-02-15-05-02-02 8mm reverse-mounted probe is widely used in a variety of critical industrial applications where accurate vibration monitoring is essential:

-

Power Generation: Used in power plants for monitoring turbines, pumps, compressors, and other vital machinery.

-

Oil & Gas: Essential in refineries and offshore platforms for keeping rotating equipment in check, including pumps, motors, and compressors.

-

Manufacturing: Applied in industries where large, high-speed machines are in use, such as steel mills, automotive plants, and paper mills.

-

Process Industries: Helps in the maintenance of machinery like mixers, grinders, and other rotating equipment in chemical processing facilities.

-

General Industrial Machinery: Provides monitoring solutions for any machinery that requires vibration analysis, including motors, blowers, and fans.

Advantages

-

High Accuracy: Delivers precise vibration readings, enabling early detection of faults before they lead to failure.

-

Versatile Installation: Reverse mounting allows easy installation in tight spaces or difficult-to-reach locations, maximizing installation flexibility.

-

Durability and Reliability: Built to last in harsh industrial environments, it offers long-term reliable performance, reducing maintenance efforts.

-

Seamless System Integration: Works perfectly with Bently Nevada’s 3300 XL system for complete vibration monitoring and predictive maintenance solutions.

-

Reduced Downtime: By providing early fault detection, the probe contributes to minimizing unexpected downtime, ensuring a more efficient and cost-effective operation.

-

Cost-Effective: Helps in reducing maintenance costs by providing advanced warning of potential issues, preventing costly machinery failures and repairs.

FAQ

-

What types of machinery can the Bently Nevada 330105-02-15-05-02-02 probe monitor?

Answer: The probe is designed for use with rotating machinery such as turbines, pumps, motors, compressors, and other similar equipment. -

How does the reverse-mount design benefit the probe?

Answer: The reverse-mount design allows for easy installation in difficult-to-access or tight spaces, increasing the versatility of the probe for various machine types and environments. -

What signal does the 330105-02-15-05-02-02 probe provide?

Answer: It provides a 4-20mA output signal or can be directly integrated into the 3300 XL vibration monitoring system for enhanced diagnostics. -

Can the probe be used in hazardous environments?

Answer: Yes, the probe is designed for industrial environments, but it is important to verify specific environmental certifications, especially for hazardous locations. -

What is the frequency range of the 3300 XL 8mm reverse-mounted probe?

Answer: The probe supports a broad frequency range suitable for most industrial machinery, typically up to 1000 Hz. -

What temperature range can the 330105-02-15-05-02-02 probe withstand?

Answer: The probe can operate in temperatures from -40°C to 85°C, making it suitable for extreme conditions in many industrial settings. -

Can the probe be used for both axial and radial vibration measurements?

Answer: Yes, the probe can measure both axial and radial vibrations in rotating machinery, offering versatility for different types of machinery. -

How is the probe installed?

Answer: The reverse-mount design allows the probe to be installed in a variety of positions, even in spaces where conventional probes would be difficult to install. -

How does the 3300 XL system enhance the functionality of the 330105-02-15-05-02-02 probe?

Answer: When integrated with the 3300 XL system, the probe provides real-time vibration data, which is crucial for effective predictive maintenance and early fault detection. -

What are the benefits of using the Bently Nevada 330105-02-15-05-02-02 probe in predictive maintenance?

Answer: The probe helps detect vibration anomalies early, which leads to more effective predictive maintenance, reducing downtime and preventing costly failures.

Related / Same-Series Model Recommendations

| Model | Description |

|---|---|

| 330105-02-12-10-02-BR | 3300 XL 8mm probe with Brazilian certification, standard configuration. |

| 330105-02-12-10-02-RU | 3300 XL 8mm probe with Russian certification, standard configuration. |

| 330105-02-12-08-02 | 3300 XL 8mm probe variant with 8mm probe diameter for specific installations. |

| 330105-02-12-15-02 | 3300 XL 8mm probe with extended 15-meter cable for large machinery applications. |

| 330105-02-12-10-05 | 3300 XL 8mm probe with 5-meter cable, optimized for general-purpose monitoring. |

| 330105-02-12-10-00 | Base version of the 3300 XL 8mm probe without regional or certification customization. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330103-11-16-10-12-05 | Standard 3300 XL 8mm probe with 5-meter cable length. |

| 330103-11-16-10-12-RU | 3300 XL 8mm probe variant designed for Russian certification requirements. |

| 330103-11-16-05-05-02 | 3300 XL 8mm probe with 2-meter cable length for compact installations. |

| 330103-11-16-10-05-05 | 3300 XL 8mm probe with 5-meter cable, optimized for general-purpose monitoring. |

| 330103-11-16-15-05-02 | Extended length probe (15-meter cable) for large machinery applications. |

| 330103-11-16-10-00-00 | Base version of the 3300 XL 8mm probe without regional customization. |

Excellent PLC

Excellent PLC