| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

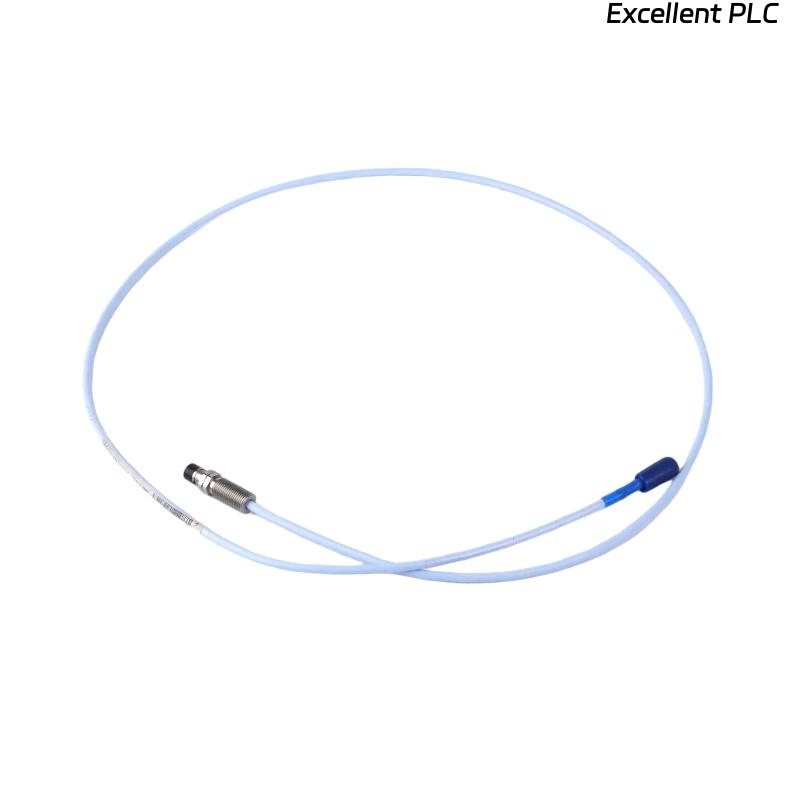

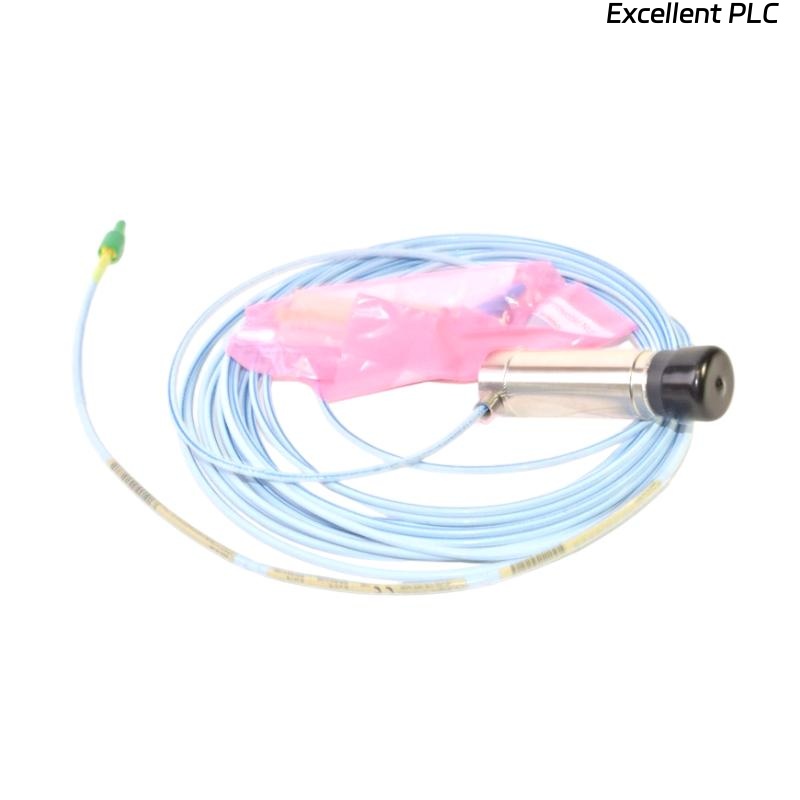

The Bently Nevada 330106-05-03-10-02-CN 3300 XL 8 mm Reverse Mount Probe is a precision-engineered proximity probe designed for shaft vibration and position monitoring in critical machinery. Part of the 3300 XL series, this reverse mount probe is specifically designed for applications requiring extended sensor reach or installation in confined spaces. Its 8 mm probe tip allows accurate radial measurements, ensuring reliable detection of vibration and shaft displacement under demanding operational conditions.

The probe is optimized for high-speed rotating machinery, including turbines, compressors, and generators. The reverse mounting capability provides flexibility for installations where standard forward-mount probes are not feasible, without compromising measurement accuracy. Combined with 3300 XL monitoring systems, it supports predictive maintenance, machinery protection, and operational safety.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330106-05-03-10-02-CN |

| Series | 3300 XL |

| Probe Type | Reverse mount proximity probe |

| Probe Tip Diameter | 8 mm |

| Measurement Range | ±0.25 mm typical displacement |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Sensor Type | Eddy current |

| Mounting Style | Reverse mount |

| Connector | Integral cable with 4-pin MIL-style connector |

| Operating Temperature | -40°C to +120°C (-40°F to +248°F) |

| Humidity | 0–95% RH, non-condensing |

| Frequency Response | DC to 20 kHz typical |

| Material | Stainless steel probe body, ceramic tip for durability |

| Maximum Shaft Speed | Up to 60,000 RPM (application dependent) |

| Certifications | CE, UL, CSA compliant |

Applications

The 3300 XL 8 mm Reverse Mount Probe is widely used for critical machinery monitoring in industries where operational reliability is essential:

-

Steam and Gas Turbines: Shaft vibration and proximity measurement for high-speed rotors.

-

Compressors: Monitoring radial vibration and displacement for centrifugal and axial compressors.

-

Generators: Detecting shaft movement to prevent mechanical damage and maintain alignment.

-

Industrial Pumps: Continuous monitoring for imbalance, misalignment, or mechanical wear.

-

Rotating Equipment in Power Plants: Provides precision measurements for machinery protection systems.

-

Petrochemical and Oil & Gas Facilities: Suitable for harsh environments and confined installations where reverse mounting is required.

Advantages

The 3300 XL 8 mm Reverse Mount Probe offers multiple benefits for industrial operations:

-

High Accuracy: Provides precise vibration and displacement measurements for predictive maintenance.

-

Reverse Mount Capability: Ideal for installations with space constraints or unusual geometry.

-

Robust Design: Stainless steel body and ceramic tip ensure durability under harsh industrial conditions.

-

High-Frequency Response: Supports high-speed rotating machinery with frequencies up to 20 kHz.

-

Ease of Integration: Fully compatible with Bently Nevada 3300 XL monitoring systems.

-

Flexible Cable Length: 1.0 meter total length allows flexible installation without additional extensions.

-

Wide Operating Temperature Range: Reliable operation from -40°C to +120°C.

-

Certified Safety and Compliance: CE, UL, CSA certifications ensure global installation compliance.

FAQ

-

What type of measurement does the 3300 XL reverse mount probe provide?

It provides radial displacement and vibration measurements using eddy current technology. -

What is the maximum shaft speed the probe can monitor?

It is suitable for shafts up to 60,000 RPM, depending on the application and system configuration. -

Can the probe be used in reverse mount applications?

Yes, it is specifically designed for reverse mount installations in confined spaces. -

What type of connector does the probe use?

It uses an integral 4-pin MIL-style connector compatible with 3300 XL monitoring systems. -

What is the probe’s frequency response?

The typical frequency response is DC to 20 kHz, suitable for high-speed machinery. -

What is the operational temperature range?

It operates reliably from -40°C to +120°C (-40°F to +248°F). -

Is the probe suitable for high-humidity or wet environments?

Yes, it supports 0–95% relative humidity, non-condensing. -

What is the measurement range of the probe?

Typical displacement range is ±0.25 mm, providing precise monitoring of shaft movement. -

Can the probe be integrated with other 3300 XL system modules?

Yes, it is fully compatible with all Bently Nevada 3300 XL monitoring modules. -

What materials are used for the probe tip and body?

The body is stainless steel, and the tip is ceramic to provide durability and wear resistance.

Related and Similar Models

| Model | Function |

|---|---|

| 330106-05-03-10-01 | 3300 XL 5 mm reverse mount probe |

| 330106-05-03-12-01 | 3300 XL 12 mm forward mount probe |

| 330106-05-03-08-01 | 3300 XL 8 mm forward mount probe |

| 330106-05-03-10-03 | 3300 XL 10 mm reverse mount probe with extended cable |

| 330106-05-03-06-02 | 3300 XL 6 mm reverse mount probe |

| 330106-05-03-08-02 | 3300 XL 8 mm reverse mount probe with high-temperature rating |

Popular Bently Nevada Models

| Model | Function |

|---|---|

| 3300 XL 330106-05-03-01 | Standard 3300 XL proximity probe for high-speed machinery |

| 3300 XL 330106-05-03-02 | Forward mount 8 mm probe for turbine monitoring |

| 3300 XL 330106-05-03-03 | Reverse mount 6 mm probe for compressors |

| 3500/92 | Complete machinery protection system with integrated monitoring |

| 3500/55 | Overspeed and gap monitoring system |

| 3300/01 | Standard proximity and vibration monitoring module |

Excellent PLC

Excellent PLC